69

CVHE-SVU01E-EN

Current Overload Protection

Motor currents are continuously

monitored for over current protection

and locked rotor protection. This

protects the Chiller itself from

damage due to current overload

during starting and running modes

but is allowed to reach full load

amps. This overload protection logic

is independent of the current limit.

The overload protection will

ultimately shut the unit down

anytime the highest of the three

phase currents exceeds the time-trip

curve. A manual reset diagnostic

describing the failure will be

displayed.

Overload protection for the motor

starts based on the Maximum Time

to Transition permitted for a

particular motor .

Running Over Current Protection

In the run mode, a “time-to-trip”

curve is looked at to determine if a

diagnostic should be called. The

UCP continuously monitors

compressor line currents to provide

running over current and locked rotor

protection. Over current protection is

based on the line with the highest

current. It triggers a manually

resettable diagnostic shutting down

the compressor when the current

exceeds the specified time-trip curve.

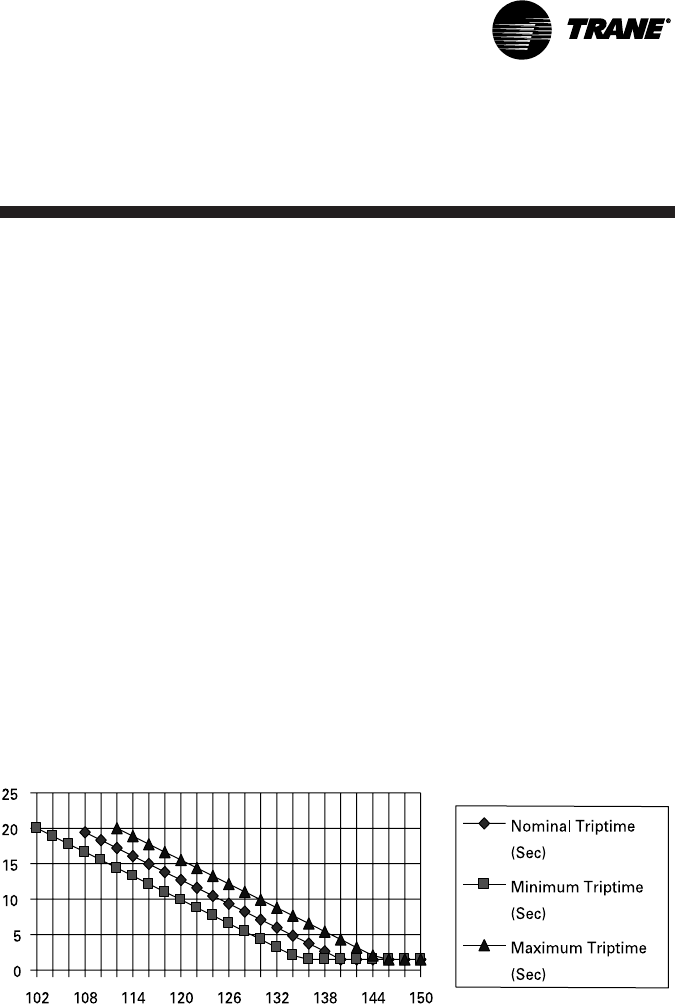

The compressor overload time trip

curve is expressed as a percent of the

Rated Load Amps of the compressor

and is not adjustable:

Overload Must Hold = 102 Percent

RLA.

Overload Must Trip in 20 (+0 -3)

seconds = 112 Percent RLA

(Note the above gives a nominal 20

second must trip point of 107 Percent

RLA.)

Overload Must Trip in 1.5 seconds =

140 Percent RLA (Nominal)

The linear time-trip curve is as

follows:

Figure 26. Overload trip time versus percent RLA

The Maximum Acceleration Time

Setting and Current Transformer

Setting are factory set however can

be set with the service tool;

Machine Protection

and Adaptive

Control