III. j - REMOTE CONDENSING UNIT REQUIREMENTS:

This section applies only to models RBC200/200RT and

RBC400/400RT. A remote condensing unit, operating on

R-404A refrigerant, is required for Blast Chill operation

on these models. The remote condensing unit should

be capable of providing 18,700 BTU/hr @ -10°F evapora-

tor temperature in a 90°F ambient environment.

4 HP air-cooled and 3 HP water-cooled remote condens-

ing units are available from Traulsen as an optional ac-

cessory. Increased capacity of the remote condensing

unit and line sizing will depend on the length and layout

of the connecting piping from the remote condensing

unit to the Blast Chill unit. Proper line sizing should be

defined by a qualified refrigeration engineer or techni-

cian.

III. k - REMOTE UNIT CUT-OUT SETTINGS:

This section applies only to models RBC200/200RT and

RBC400/400RTRT. The low pressure cut-out of the re-

mote condensing unit should be adjusted to obtain an

evaporator coil temperature NO LOWER THAN -15°F. If

the length of the connecting piping is 40 feet or less, the

condensing unit low pressure cut-out settings will be

approximately 15 +/- 2 PSIG cut-out and 25+/- 3 PSIG

cut-in.

III. l - SEALING ROLL-IN/ROLL-THRU UNITS:

This section applies only to models RBC200/200RT and

RBC400/400RTRT Roll-In and Roll-Thru cabinets set

on the floor require the floor area to be flat and level. In

addition, after the cabinet is set in place, sealant should

be used around the perimeter of the base to comply with

NSF International requirements. After sealing the unit,

the enclosed ramp should then be installed.

III. m - ON/OFF SWITCH:

The Traulsen Blast Chiller models are all equipped with

a power ON/OFF switch intended to cut power to the

control as needed. In the event of routine maintenance

and/or service is needed, be certain to disconnect the

electrical power to the machine and follow lockout/tagout

Procedures.

This is located on top of models RBC100, RBC200,

RBC200RT, RBC400 and RBC400RT behind the louver

panel assembly. On model RBC50, this switch is located

on the right side of the control tower.

III. INSTALLATION (continued)

-7-

Front

Of Unit

Front

Of Unit

Floor

Drain

Evaporative

Pan Kit

Fig. 8

↑↑

↑↑

↑

↑↑

↑↑

↑

Front

Of Unit

Evaporative

Pan Kit

↑↑

↑↑

↑

Pipe

Thread

Plug

Fig. 7

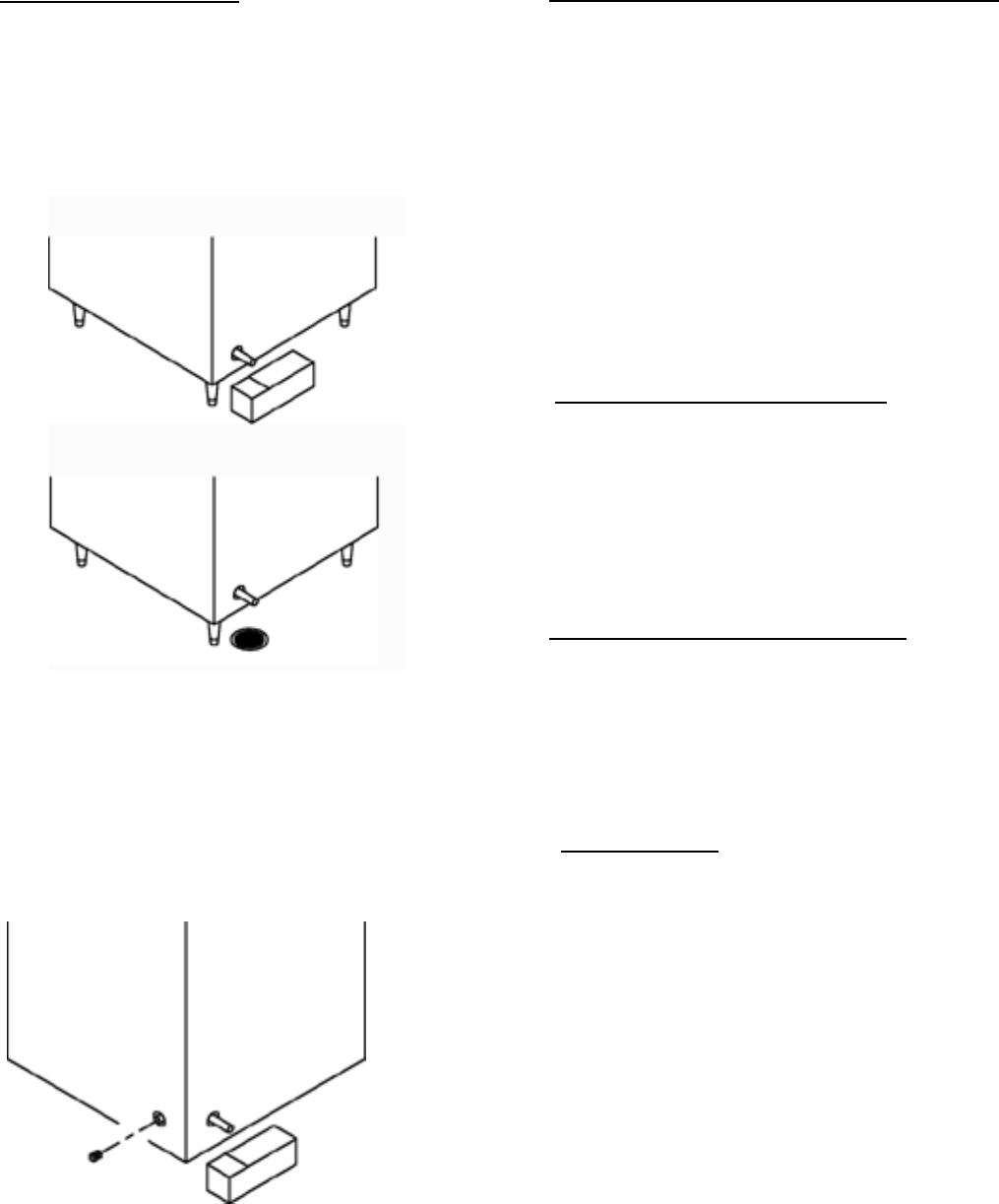

III. i - CONDENSATE REMOVAL:

All Traulsen Blast Chill models (except model RBC50)

require the use of a floor drain or floor mounted electric

condensate evaporator.

Model RBC100 requires either a floor drain or the use of

an optional bottom mounted electric condensate evapo-

rative pan kit (BCACC-BMCE) for condensate removal.

The standard drain port location is at the rear of the unit

(see figure 7).

Models RBC200 and RBC200RT require either a floor

drain or the use of an optional floor mounted electric

condensate evaporative pan kit (BCACC-FMCE) for con-

densate removal. Two drain ports are provided, located

at the right side and rear of the unit. Plug the unused

drain port with the male pipe thread plug supplied (see

figure 8).

NOTE: Local code should be consulted when plumbing

to drain port.