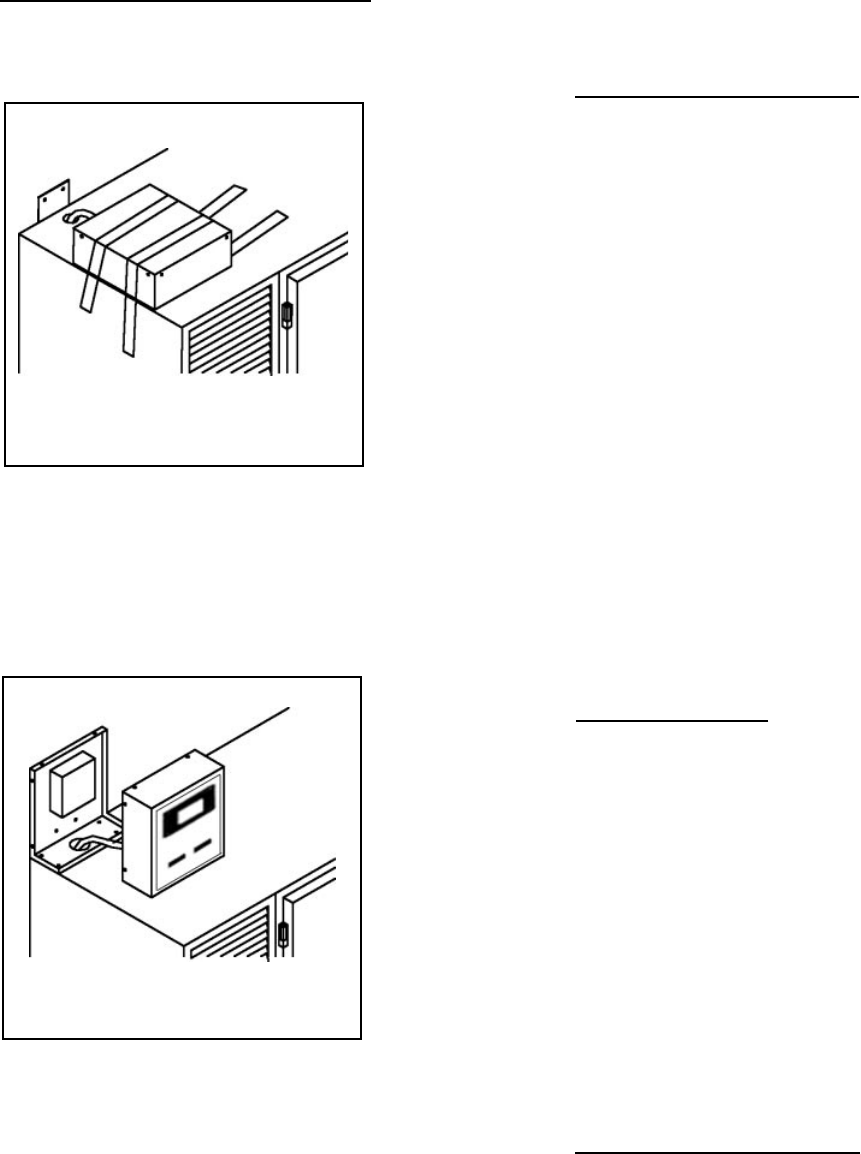

III. n - INSTALLING RBC50 CONTROL PANEL:

Model RBC50 is shipped with the control panel detached,

and laid flat, taped to the cabinet top (see figure 9). This

must be installed before use. To install:

Remove the packing material and tape holding the con-

trol to the top. Remove and retain the six (6) Phillips head

screws attaching the control cover to the frame. Also, re-

move and retain the 1/4- 20 x 1/2” screws found in the

cabinet top. Next, position the control frame over the hole

in the unit top and attach using 1/2-20x1/2” screws (see

figure 10).

NOTE: Extreme care needs to be taken to insure that:

a- all wires connecting the control cover to the RBC50 are

not damaged in any way, nor mistakenly mounted between

the cover and cabinet during installation, which could re-

sult in a short circuit, or...

b- that no connections are pulled off the control.

NOTE: Ensure that grommet is firmly in place, aligning

round hole in bottom of control housing with round hole

in unit top.

Inspect paper roll, label roll, and spindles from rear of con-

trol panel before installing panel. Reattach the control

cover to the frame using the six (6) Phillips head screws

previously removed.

III. INSTALLATION (continued)

-8-

Fig. 9

Fig. 10

IV. CARE & MAINTENANCE

WARNING: DISCONNECT ELECTRICAL POWER

SUPPLY BEFORE CLEANING ANY PARTS OF THE

UNIT.

IV. a - CLEANING THE CONDENSER:

The most important thing you can do to insure a long,

reliable service life for your Traulsen is to regularly

clean the condenser coil. The self-contained condens-

ing unit requires regularly scheduled cleaning to keep

the finned condenser clean of lint and dust accumula-

tion. Keeping the condenser clean allows the cabinet

to operate more efficiently and use less energy.

To clean the self-contained condenser, first discon-

nect electrical power to the cabinet and lift up the front

louver assembly. To lift this, remove the two screws

located on both sides at the bottom of the louver as-

sembly. Once the screws are removed, the panel can

be pivoted upwards allowing full access to the front

facing condenser (for model RBC50, remove the four

Phillips head screws from the front louver panel, and

lift-off). Vacuum or brush any dirt, lint or dust from

the finned condenser coil, the compressor and other

cooling system parts. If significant dirt is clogging

the condenser fins, use compressed air to blow this

clear. Lower louver assembly and replace screws to

hold it in place. For care of the remote condensing

unit(s) used for models RBC200 & RBC200RT, consult

the manufacturer’s product literature.

IV. b - PRINTER SUPPLIES:

Supplies to support the both standard SmartChill

®

control printers are available directly from our Parts

Department, or from your local Hobart Sales and

Service Office. In addition it may also be possible to

obtain one of these locally. The record printer paper is

standard thermal paper which is readily available at

most office supply outlets. Specifications are 2-1/2"

wide by 85" long:

Traulsen P/N 400-60003-00

Office Depot #302-224

Staples #PMF-5233

The label printer uses a special peel-off label stock,

Traulsen part number 400-60004-00. Each roll contains

225 labels.

IV. c - INSTALLING PRINTER PAPER:

To load the record printer paper, place a roll on the roll

shaft. Position the paper such that the paper feeds

from the back of the roll. This allows the thermal sen-

sitive side of the paper to be on the upper surface as it

feeds through the printer. The ends of the roll shaft

are installed in the two roll holders.

Gently pull the feed door down and slightly forward. It

is located on the bottom of the printer and will open

about 90 degrees. Feed the paper into the loading slot

directly behind the door and push it up until the paper