VENTILLATION REQUIREMENTS

A single WFGA-60FS gas-fired fryer requires a minimum of 700 cubic

feet per hour (12 CFM) make-up air. The ventilation for the kitchen

must have sufficient capacity to prevent a negative-pressure condition.

DO NOT obstruct or restrict ventilation and make-up air required to

support combustion.

PLUMBING INSTALLATION

The installation of this fryer must conform to local codes. In the

absence of local codes, the installation of this fryer must conform with

the National Fuel Gas Code (ANSI Z223.1). In Canada, the National

Gas Installation Code (CAN/CGAB149.2) is applicable.

In any instance where gas supply pressure is in excess of 15” water

pressure (1/2 psi or 3.45kP), the fryer must be isolated from the supply

piping by closing its two individual manual shut-off valves (see fig. 3).

IMPORTANT: Failure to isolate the fryer from excessive pressure will

damage the gas valves and allow raw gas to leak into the room.

This fryer is orificed at the factory for natural gas at a pressure of 3.5” of

water column. The installed orifice is suitable for use at -280 to 2999

feet (-85 to 914 meters) elevation. It is the responsibility of the installer

to install the factory recommended orifice and pressure regulator kit

suitable for the fuel type and elevation at the final installation site.

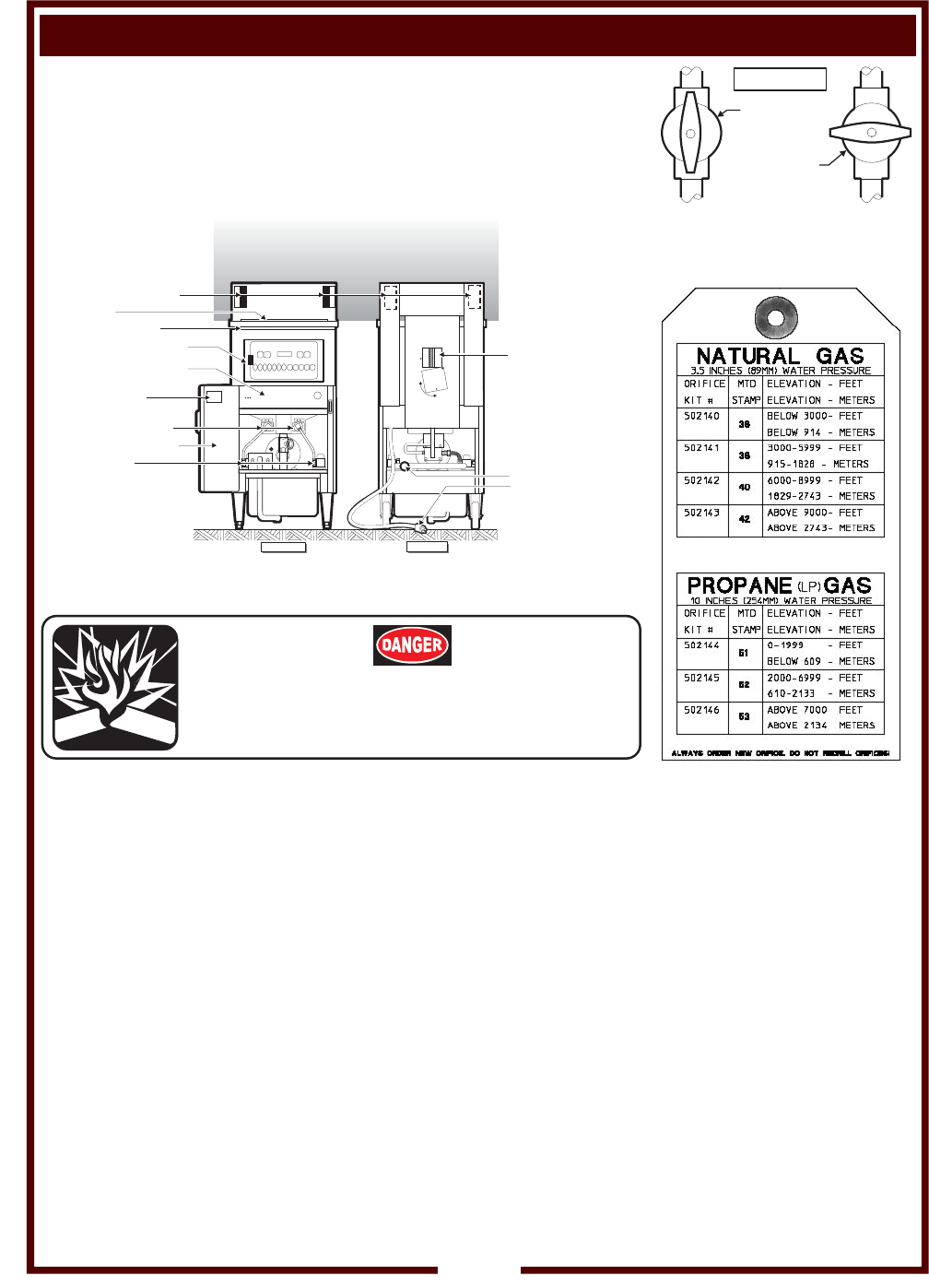

The red tag (p/n 301217) attached to the gas connection provides

pressure settings and part numbers for conversion kits applicable to

various fuels and altitudes. (See fig.4 below)

INSTALLATION (continued)

7

Fig. 3 Gas Shut-Off Valves

Fig. 4 Fuel and Altitude

Conversion Tag

NOTE: Failure to install

proper orifices can burn

cooking oil and cause

potential burner and flue

system failure. Damaged

caused by improper orifice

installation is NOT covered

by warranty.

IMPORTANT:

Conversion for fuel and/or

altitude must be performed by

a licensed plumber certified in

gas installation only.

371 301098 OpManual for WFGA-60FS Gas Fryer

FIRE AND EXPLOSION HAZARD

GAS CONNECTIONS AND GAS ADJUSTMENTS MUST BE MADE BY

A LICENSED PLUMBER, CERTIFIED IN GAS INSTALLATION.

A gas explosion will cause death or serious injury

GAS VALVE

OPEN

CLOSED

FRONT VIEW

BACK VIEW

KEEP THIS AREA CLEAR

14. EXHAUST GAS FLUE

16. COOLING SLOT

23. DATA PLATE

LIFT MOTOR

ACCESS

23. GAS CONNECTION

22. ELECTRICAL

CONNECTION

UPPER CONTROL PANEL

LOWER CONTROL PANEL

FRONT ACCESS DOOR

BURNER ASSEMBLIES

GAS VALVES

FRYPOT