Installation

9

Ventilation

DIRECT FLUE ARRANGEMENT

When the installation of a mechanically driven ex-

haust hood is impractical the oven may be vented

by a direct flue arrangement.

WARNING!!

It is essential that the direct flue be

installed as follows. Incorrect installation

will result in unsatisfactory baking and

oven damage.

ThefluemustbeclassBorbetterwithadiameter

of 10” (25.4 cm). The height of the flue should rise

6-8 ft (2-2.5 m) above the roof of the building or any

proximate structure. Never direct vent the oven

into a hood. The flue should be capped with a UL

Listed type vent cap to isolate the unit from exter-

nal environmental conditions.

Thedirectventcannotreplaceairconsumedand

vented by the oven. Provisions must be made to

supply the room w ith sufficient make-up air. Total

make-up air requirements for each oven section

should be approximately 30 CFM per section. To

increase the supply air entering the room, a ven-

tilation expert should be consulted.

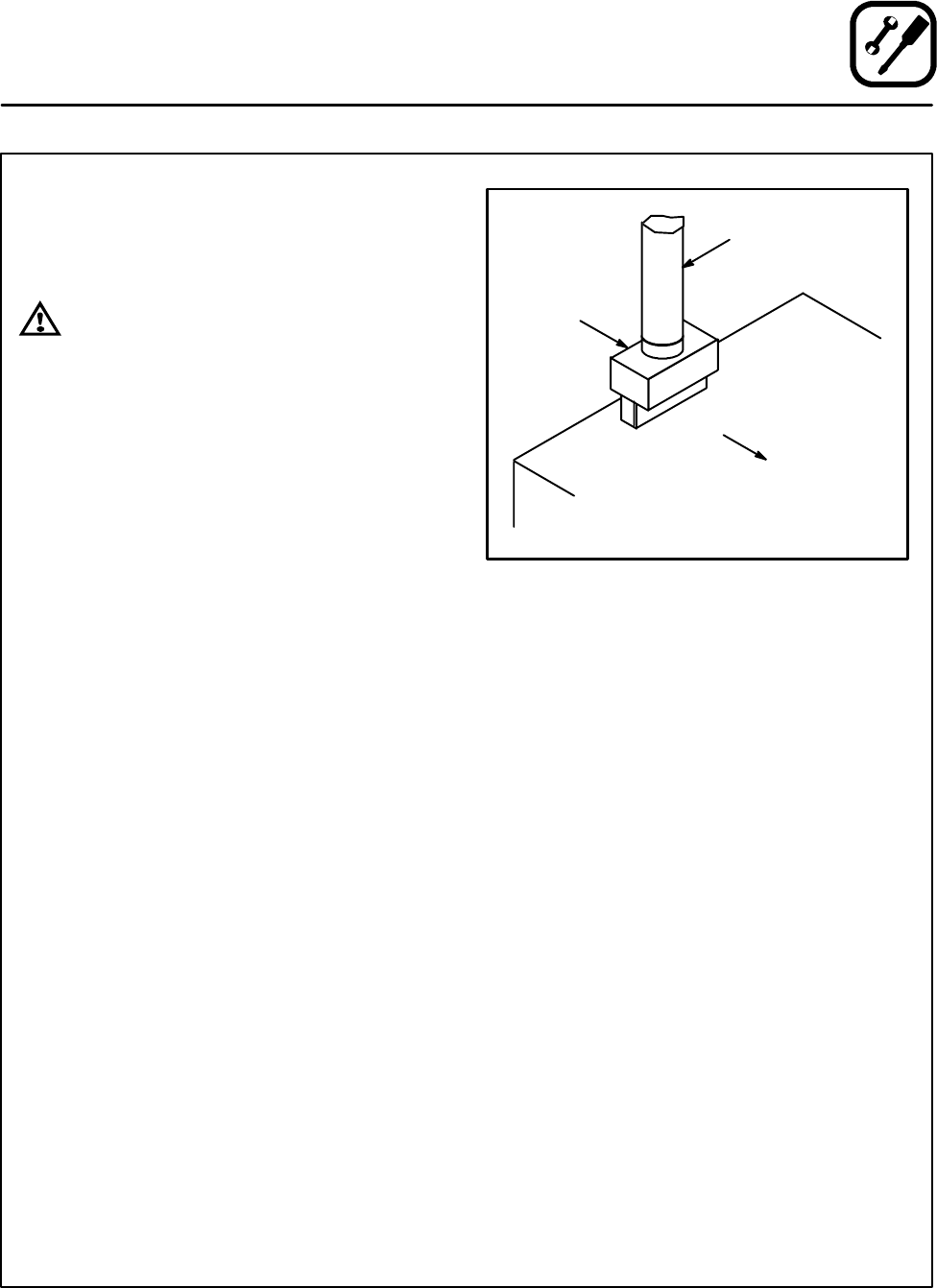

Installing the draft hood

Ovens ordered for direct venting are supplied with

a draft hood. Install the draft hood as follows:

1. Place the draft hood over the flue connector.

SeeFigure7.

2. Secure both ends with the sheet metal s crew s

provided.

Front of

Oven

Draft Hood

Flue

Figure 7

VENTING PROBLEMS

Blodgett gas deck ovens use the natural principal

of heat rising as the basic method of ventilation.

If the venting of any deck oven is either restricted

or forced in any w ay the baking characteristics of

theovenwillbeadverselyaffected.

Examples of forced venting include:

D installation of a fan in a direct vent pipe

D use of a canopy type hood w ithout t he draft di-

verter

Examples of restricted venting include:

D use of tees and elbows

D long horizontal runs

Insufficient make-up air can cause heated air and

combustibles to remain in the oven shortening the

life of the components.