Installation

12

Gas Connection

PRESSURE REGULATION AND TESTING

Each section of the 1060-B series oven is rated at

120,000 BTU per hour (35.2 kW). The 1060-BL se-

ries ovens are rated at 85,000 BTU per hour (24.9

kW). At full demand, each section 1060-B requires

120 cubic feet per hour (3.2 m

3

) Natural gas or 47

cubic feet per hour (1.3 m

3

)Propanegas.Each

section 1048-BL oven requires 85 cubic feet per

hour (2.4 m

3

) Natural gas or 33 cubic feet per hour

(0.9 m

3

) Propane gas. Each oven has been ad-

justed at the factory to operate with the type of gas

specified on the rating plate.

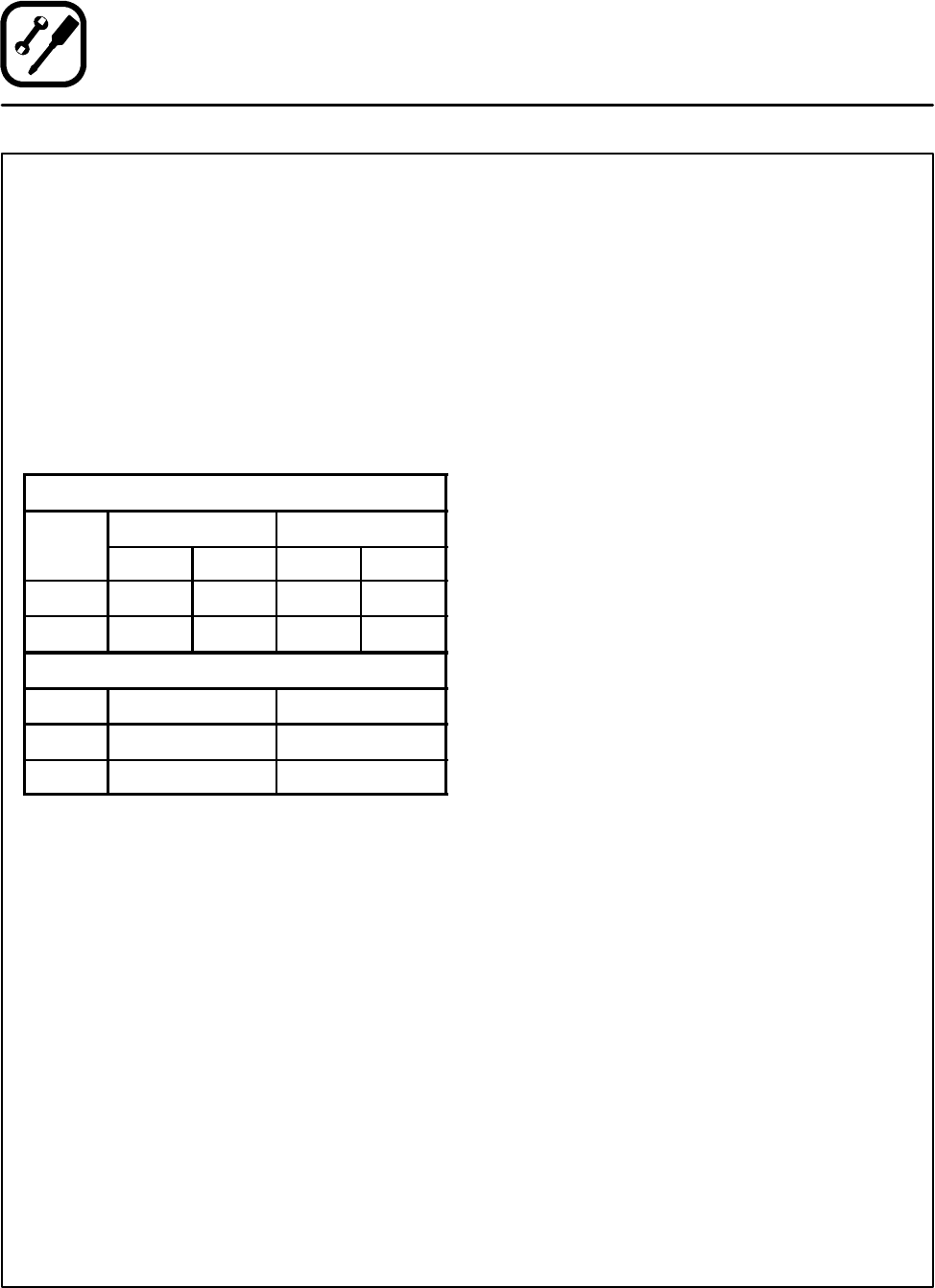

Inlet Pressure

Natural Propane

Min Max Min Max

W.C. 7.0 10.5 11.0 13.0

kPa 1.43 2.61 2.74 3.23

Manifold Pressure

Natural Propane

W.C. 3.5 10.0

kPa .87 2.49

D Inlet Pressure --- the pressure of the gas before

it reaches the oven.

D Manifold Pressure --- the pressure of the gas

as it enters the main burner(s).

D Min --- the minimum pressure recommended to

operate the oven.

D Max --- the maximum pressure at which t he

manufacturer warrants the oven’s operation.

Each oven is supplied with a regulator to maintain

the proper gas pressure. The regulator is essen-

tial to the proper operation of the oven and

must be installed. It is preset to provide the oven

with 3.5” W.C. (0.87 kPa) for natural gas and 10.5”

W.C. (2.50 kPa) for Propane at the manifold.

DO NOT INSTALL AN ADDITIONAL REGULATOR

WHERE THE OVEN CONNECTS TO THE GAS

SUPPLY UNLESS THE SUPPLY EXCEEDS THE

MAXIMUM PRESSURE.

Due to the decrease in oxygen at higher eleva-

tions, above 2000’ , the unit may need to be re-

rated. (The orifice size may need to be adjusted to

accomodate different air pressures at higher

elevations.) If not rerated, incomplete combustion

may occur releasing Aldehydes and CO or Carbon

Monoxide. Any of these are unacceptable and

may be hazardous to the health of the operator.

Prior to connecting the oven, gas lines should be

thoroughly purged of all metal filings, shavings,

pipe dope, and other debris. After connection, the

oven should be checked for correct gas pressure.

Installation must conform with local codes, or in

the absence of local codes, with the National Fuel

Gas Code, NFPA 54/ANSI Z223.1 ---Latest Edition,

the Natural Gas Installation Code CAN/CGA-

B149.1 or the Propane Installation Code, CAN/

CGA-B149.2 as applicable.

The oven and its individual shutoff valve must be

disconnected from the gas supply piping system

during any pressure testing of that system at test

pressuresinexcessof1/2psig(3.45kPa).

The oven must be isolated from the gas supply

piping system by closing its individual manual

shutoff valve during any pressure testing of the

gas piping system at test pressures equal or less

than 1/2 psig (3.45kPa).