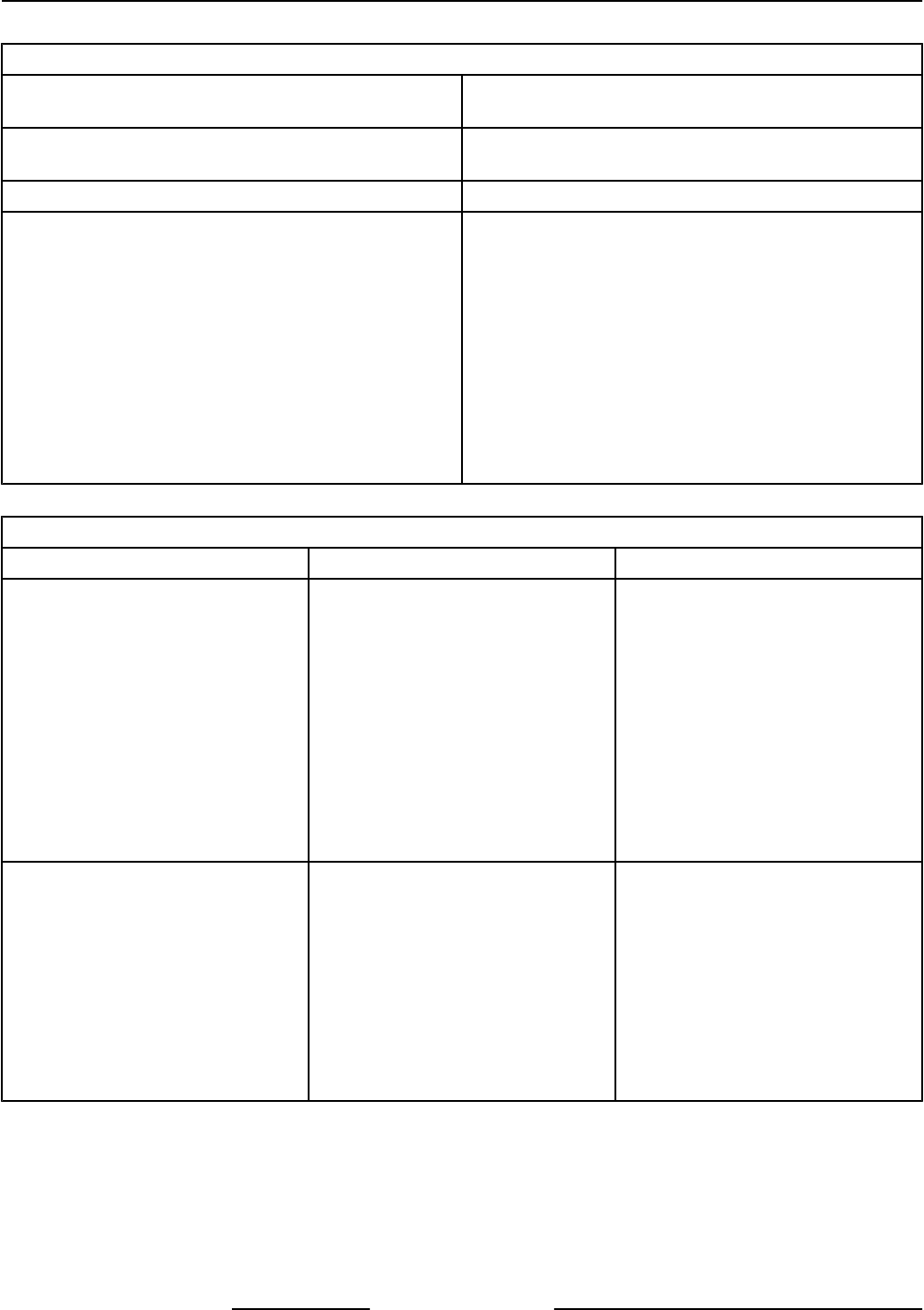

Clean Cycle Troubleshooting (KA7E Only)

Nothing seems to be happening in clean mode.

1. Time delays are programmed between steps during

clean cycle. This is normal operation.

Oven uses too much chemical.

1. Typical usage is approximately 1/2 gallon per day.

Contact Product Service.

Grease or liquids running outside of oven. 1. Pump tubing needs to be replaced.

Chemical pump not pulling chemical cleaner.

1. Chemical bottle may be empty.

2. Ensure tubing is cut at an angle and that standpipe

is in place to prevent tube from curling inside

chemical bottle.

3. Check chemical pump ON time (P31).

4. Clog inside hose inlet or outlet.

5. Hose leaking or air gaps at connections.

6. Pump not receiving power or malfunction.

7. Control board malfunction.

Clean Cycle Troubleshooting - Error Messages (KA7E Only)

Display Shows When Displayed Cause

ERROR 1

CHECK DETERGENT

OR

CHECK DETERGENT

CHECK DETER PUMP

When cleaning agent flow from

container into sump is not detected by

sensor.

1. Insufficient liquid level in

cleaning agent bottle.

2. Pick up tube not submerged in

cleaner. Ensure tubing is cut at

an angle and that standpipe is in

place to prevent tube from

curling inside chemical bottle.

3. Defective hose (broken,

squeezed closed).

4. Chemical pump or control not

working. Test in P22.

ERROR 2

PRESS STOP

OR

ATTEMPTING TO

DRAIN SUMP

DRAIN FAIL

CHECK DRAIN, PUMP

When there is water in the sump at

the start of a clean cycle.

1. Oven drain plugged/not flowing.

2. Drain pump plugged.

3. Drain pump fails to operate or

control not working. Test in P22.

KA SERIES ELECTRIC ROTARY OVENS - TROUBLESHOOTING

F25294 Rev. A (0412) Page 66 of 72