REPLACING CYLINDERS —

SINGLE PANE GLASS

When cylinders need to be replaced, the lifting

force of the cylinder must be known. The lifting

force can be determined by the data printed on the

cylinder being replaced. The following shows the

part number for the 300N and 400N cylinders.

300N Cylinder – P/N 0412539

400N Cylinder – P/N 0406925

1. Raise the front glass to open completely.

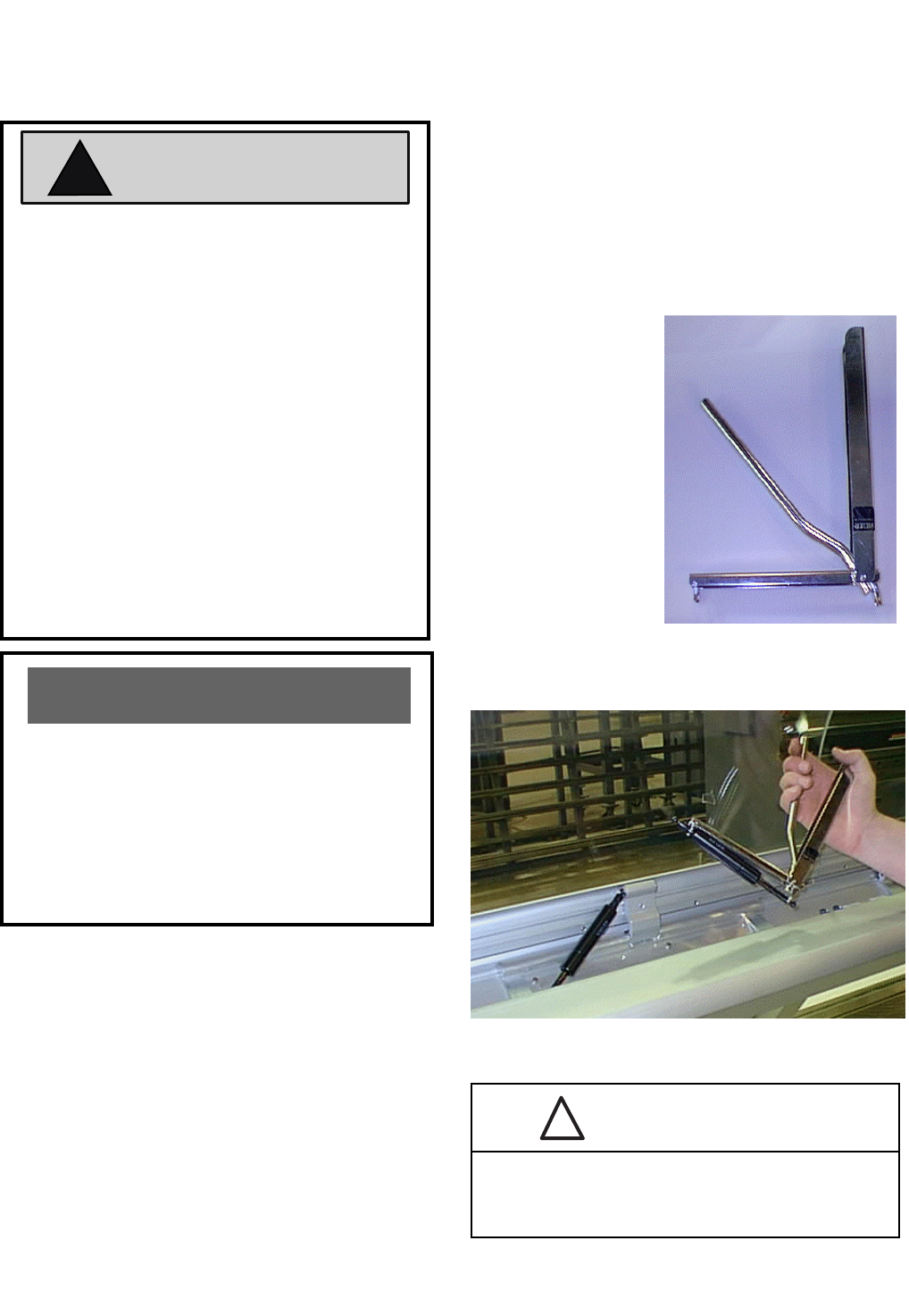

2. Use special hand tool, shown in photo, to

compress and remove cylinder.

Note: Cylinders cannot be removed without

special hand tool.

Cylinder

Removal

Tool

P/N 0425326

P/N 0420057_B 6-5

Service Merchandisers

HUSSMANN CORPORATION, Bridgeton, MO 63044-2483 U.S.A.

Cylinder rods must point down so

oil will lubricate the rod and seals. Failure to

lubricate will severely shorten cylinder life.

CAUTION

!

Removing a Cylinder

Check each glass section monthly to

determine if support cylinders are worn

and need to be replaced. If the glass

does not stay in a raised position, have

the cylinders replaced.

Each front curved glass section weighs

about 40 lb (18 kg). To prevent glass

from falling during installation, use or

maintenance and causing injury to

customers or personnel, Hussmann

recommends one person hold the glass

in a raised position while the other

person performs cylinder replacement.

Support the front glass at all times until

cylinder is replaced or the glass is low-

ered.

Cylinders are a wear item.

They are designed:

• to support the glass when fully open.

• to allow the glass to come down

(or close) slowly.

Have your Service Contractor replace the

cylinders when required.

NOTICE

WARNING

!