NSF CERTIFICATION

These merchandisers are manufactured to meet

ANSI / National Sanitation Foundation (NSF

®

)

Standard #7 requirements. Proper installation is

required to maintain certification. Near the serial

plate, each case carries a label identifying the

type of application for which the case was certi-

fied.

ANSI/NSF-7 Type I – Display Refrigerator / Freezer

Intended for 75°F / 55%RH Ambient Application

ANSI/NSF-7 Type II – Display Refrigerator / Freezer

Intended for 80°F / 55%RH Ambient Application

ANSI/NSF-7 – Display Refrigerator

Intended for Bulk Produce

LOCATION

These merchandisers are designed for displaying

products in air conditioned stores where tempera-

ture is maintained at or below the ANSI/NSF-7

specified level and relative humidity is main-

tained at or below 55%.

Placing refrigerated merchandisers in direct sun-

light, near hot tables or near other heat sources

could impair their efficiency.

Like other merchandisers, these are sensitive to

air disturbances. Air currents passing around

merchandisers will seriously impair their opera-

tion. Do NOT allow air conditioning, electric

fans, open doors or windows, etc. to create air

currents around the merchandisers.

Product should always be maintained at proper

temperature. This means that from the time the

product is received, through storage, preparation

and display, the temperature of the product

must be controlled to maximize the life of the

product.

P/N 0420057_B 1-1

Service Merchandisers

HUSSMANN CORPORATION, Bridgeton, MO 63044-2483 U.S.A.

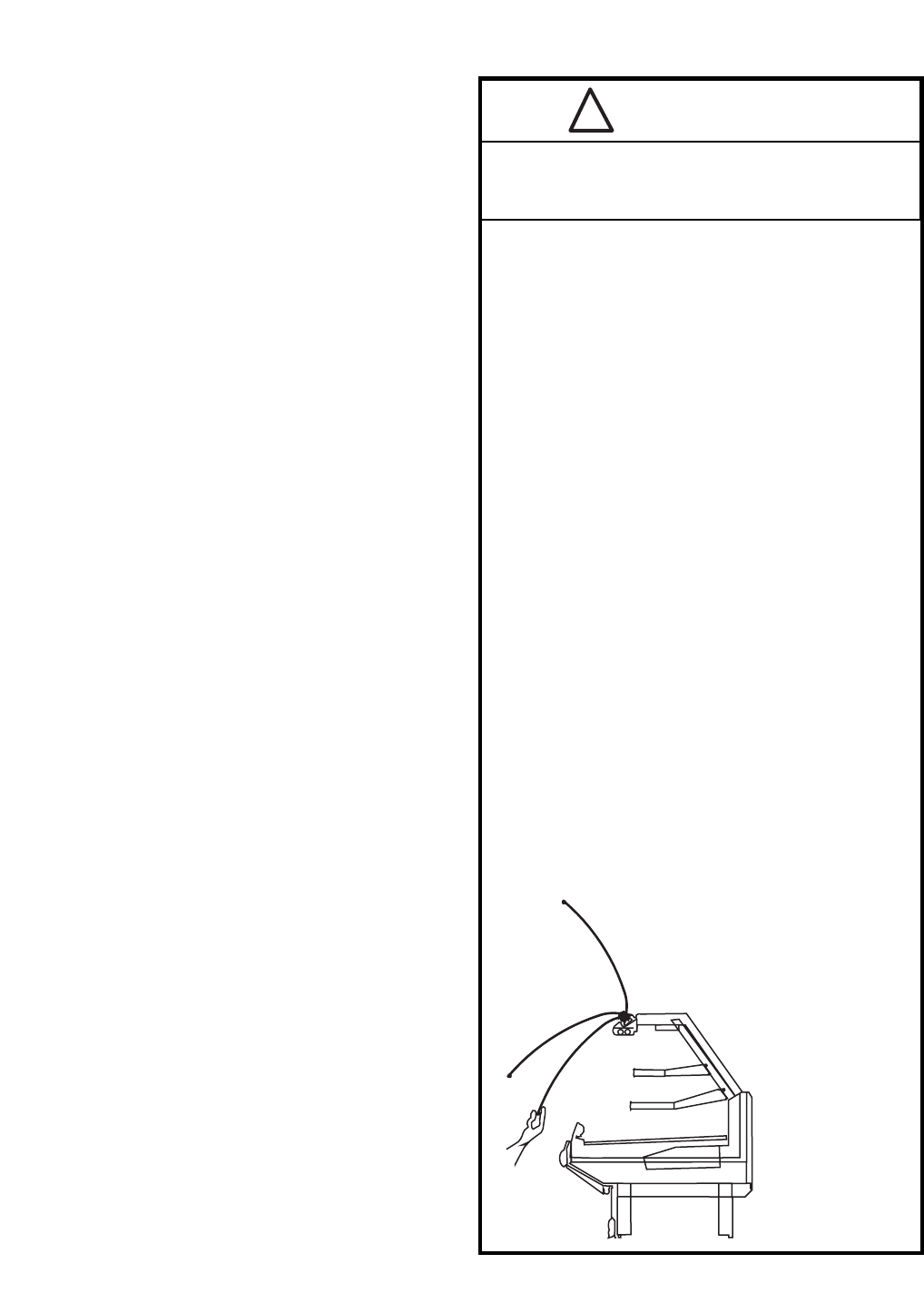

INSTALLATION

The top cylinders, which allow the raising and

lowering of this glass, have been carefully

installed and tested for the proper tension before

shipment. However, during shipment and stor-

age, the lubricant inside the cylinders may have

settled. This settling can cause excessive or

uneven tension on the glass to the point of

breakage.

To avoid any damage, please do the follow-

ing before completely raising the front

glass.

1. Slowly raise and lower each glass section

6 times to a height of 6 in. (152 mm).

2. Increase the height to about 12 in. (305

mm) and raise and lower the glass 6 times.

3. Then raise the glass to the full extension

and lower.

This should release any settled lubricant in the

cylinders and prevent any stress on the front

glass.

Leveling and adjustment

procedures begin on

Page 1-3.

Read before raising front glass to prevent

injury from broken or falling glass.

CAUTION

!

6 in.

6 in.