Now attach the drive coupler from the spin motor to the

reel. In most cases, town wobble extensions work well.

Figure 3-8

Be sure the extension is as straight as possible. Ad-

justing the spin motor on its bracket may be necessary.

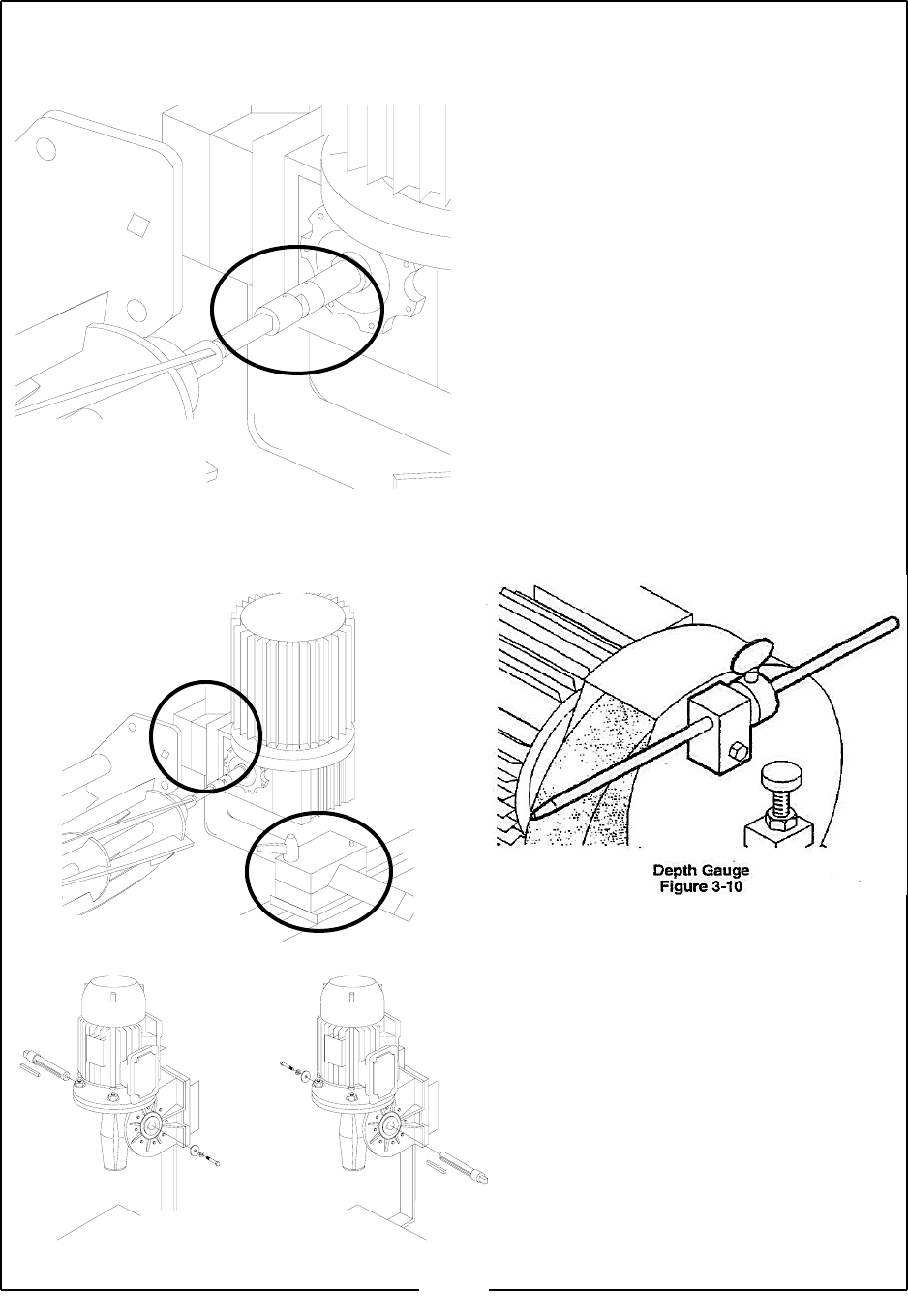

Good alignment eliminates drive line chatter. Figure 3-

9

NOTE

The spin motor shaft must be removed and in-

stalled on the opposite side of the drive unit for

left drive reels. Do not turn drive assembly

around on work table bars. (Fig 3-9A)

Once these steps have been completed, all mounting

brackets on the reel unit and bases should be se-

curely tightened. When grinding reels of the same

make and model, subsequent units will be easier to

place after the initial setup.

7. Close the rear canopy.

8. Open the front canopy.

9. A depth gauge is supplied to check that the reel’s

center shaft is parallel with the wheel head travel.

Loosen the screw in the alignment stem collar

and slide the alignment stem for ward until it

makes contact with the reel’s center shaft.

Tighten the screw in the collar and remove depth

gauge. Move carriage to opposite end of the reel

and repeat instructions; taking notice of any dif-

ferences, make adjustments accordingly. Figure

3-10

10. After checking the alignment, remove the depth

gauge and close the front canopy.

11. Start the spin motor.

12. Adjust the dial on the RPM control to the proper

speed setting for the diameter of the reel being

ground. Refer to the chart located on the front

panel for the proper setting. Figure 3-11

15

Wobble Extensions

Figure 3-8

Spin Motor Brackets

Figure 3-9

Shaft Being Reversed

Figure 3-9 A