REEL

DIAMETER

REV/MIN DIAL

READING

4 375 10.00

5 300 7.70

6 250 6.25

7 215 5.40

8 190 4.75

9 170 4.30

10 150 3.80

RPM Setting

Figure 3-11

13. Start the wheel head.

PROLONGED CONTACT BETWEEN THE STONE

AND REEL MAY CAUSE THE STONE TO CHIP OR

BREAK APART, CAUSING SERIOUS INJURY TO

THE OPERATOR. DAMAGE TO THE REEL MAY

ALSO RESULT.

14. With the carriage in the center of the reel, care-

fully adjust wheel head “in” toward reel until slight

contact is made. Manually move grinding car-

riage left and right. If excessive vibrations or loud

grinding sounds occur, quickly adjust wheel head

“out,” away from the reel or press the “master kill”

button. Check mounting brackets, reel bearings,

etc., to make sure all are secure.

NOTE

Sometimes reels wear in either a concave or convex

fashion. If the grinding wheel makes contact with the

reel only in the center it indicates convex wear. Set

limit stops so wheel head travels just beyond points

of contact. Read through the following steps, then

grind reel until contact is make throughout wheel

head’s range of travel. Repeat step 15. If no contact

is made beyond points just ground, move limit stops

out slightly and regrind. Continue this procedure until

contact is make throughout entire length of reel. If

wear is concave, reel will have to be ground at each

end. Set limit stops as indicated by step 6 and grind

until contact is make throughout entire length of reel.

15. If the results of step 14 are satisfactory, engage

and start traverse.

Engaging Traverse

5100 Series—Traverse engage lever is located on

the left side of the carriage plate. Move it to the cen-

ter position.

16. Start the coolant pump, using only a “trickle” of

coolant for spin grinding.

17. Begin the spin grinding operation. Grind the reel

until the leading edge has a square and sharp

edge. For best results, infeed the wheel at

0.001” (one tooth per stroke). See the following

instructions to set the auto infeed indexing ratchet

wheel.

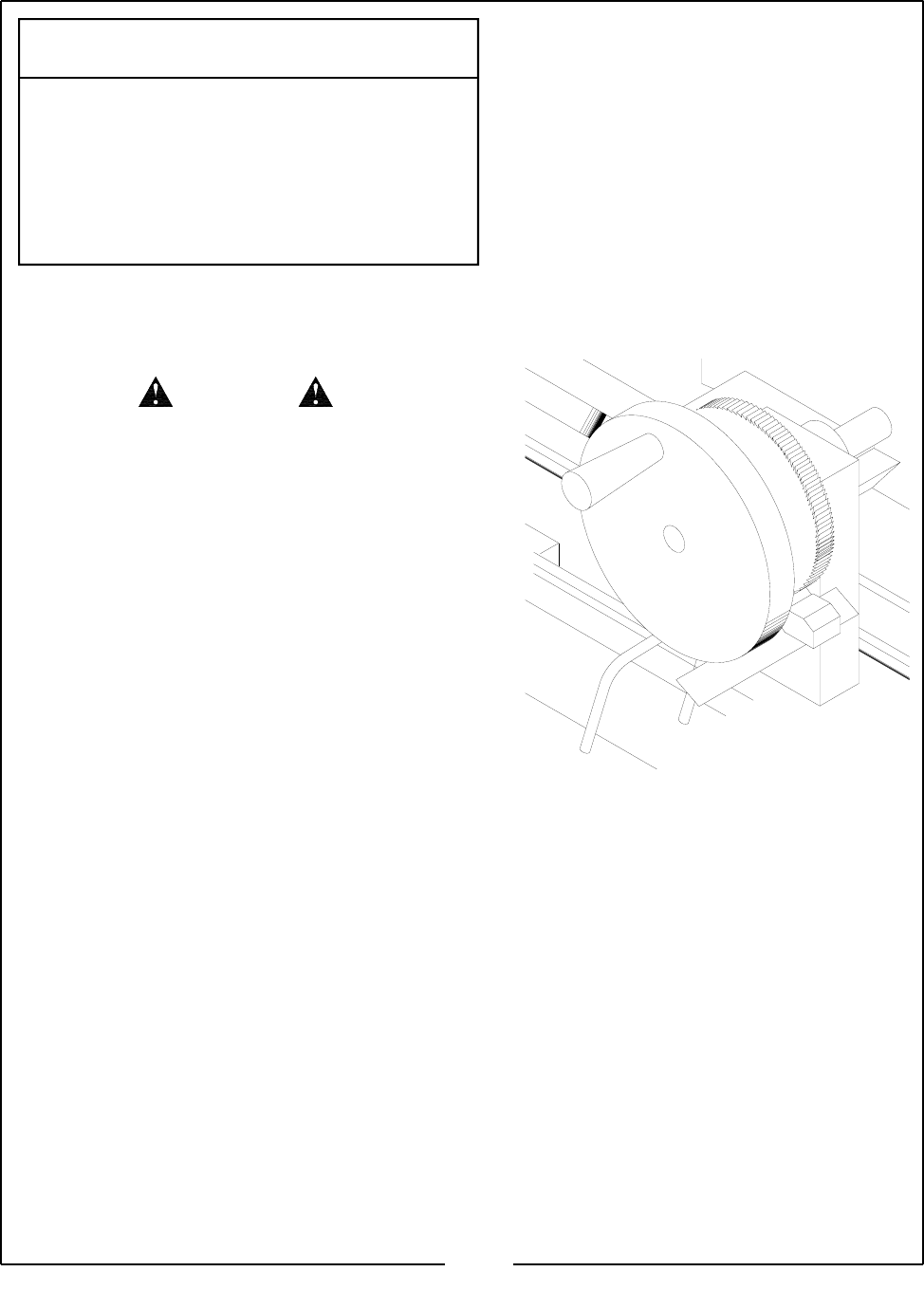

Indexing The Ratchet Wheel

The ratchet wheel, located just behind the hand

wheel, is used to automatically index the amount of

“in-feed” of the wheel head. Figure 3-12

The amount of “in-feed” per traverse cycle is set by

adjusting the screw on the center limit stop. One, two

or three teeth can be indexed, infeeding the grinding

wheel 0.001, 0.002 or 0.003 inch per traverse cycle

respectively.

IMPORTANT

For reels, only 0.001 inch per traverse cycle

is recommended by the manufacturer.

NOTE

The distance of travel will vary slightly with

the speed of travel. The carriage will

“overrun” the return stop if the speed is in-

creased without readjusting the screw.

CAUTION

16

Ratchet Wheel

Figure 3-12