Improved

Acoustical

Performance

5

RLC-PRC005-E4

The sound levels of the Series R Model

RTAA have been steadily improved

since its introduction. With the advent of

the Model RTAC, sound levels are

reduced significantly by addressing two

major sources: the compressor and the

refrigerant piping. First, the compressor

has been specifically designed to

minimize sound generation. Second, the

refrigerant components and piping have

been optimized to reduce sound

propagation throughout the system. The

result: sound levels achieved on the

Model RTAC represent the lowest sound

levels ever on Trane air-cooled helical-

rotary compressor water chillers.

Superior Efficiency Levels:

The Bar Has Been Raised

The standard-efficiency Trane Model

RTAC has COP levels up to 2.90 kW/kW

[9.9 EER] (including fans), while the

premium-efficiency, or high-efficiency,

units leap to COP levels of 3.08 kW/kW

[10.51 EER] (including fans).

The modern technology of the RTAC

with the efficient direct-drive

compressor, the flooded evaporator, the

unique design to separate liquid and

vapor, the electronic expansion valve,

and the revolutionary Tracer

™

Chiller

Controls, has permitted Trane to achieve

these efficiency levels, unmatched in the

industry.

Precise Rotor Tip Clearances

Higher energy efficiency in a helical-

rotary compressor is obtained by

reducing the rotor tip clearances. This

next-generation compressor is no

exception. With today’s advanced

manufacturing technology, clearances

can be controlled to even tighter

tolerances. This reduces the leakage

between high- and low-pressure cavities

during compression, allowing for more

efficient compressor operation.

Capacity Control and Load Matching

The combination patented unloading

system on Trane helical-rotary

compressors uses the variable

unloading valve for the majority of the

unloading function. This allows the

compressor to modulate infinitely, to

exactly match building load and to

maintain chilled-water supply

temperatures within ± 0.3°C [±0.5°F] of

the set point. Reciprocating and helical-

rotary chillers that rely on stepped

capacity control must run at a capacity

equal to or greater than the load, and

typically can only maintain water

temperature to around ± 1°C [±2°F].

Much of this excess capacity is lost

because overcooling goes toward

removing building latent heat, causing

the building to be dried beyond normal

comfort requirements. When the load

becomes very low, the compressor also

uses a step unloader valve, which is a

single unloading step to achieve the

minimum unloading point of the

compressor. The result of this design is

optimized part-load performance far

superior to single reciprocating

compressors and step-only helical-

rotary compressors.

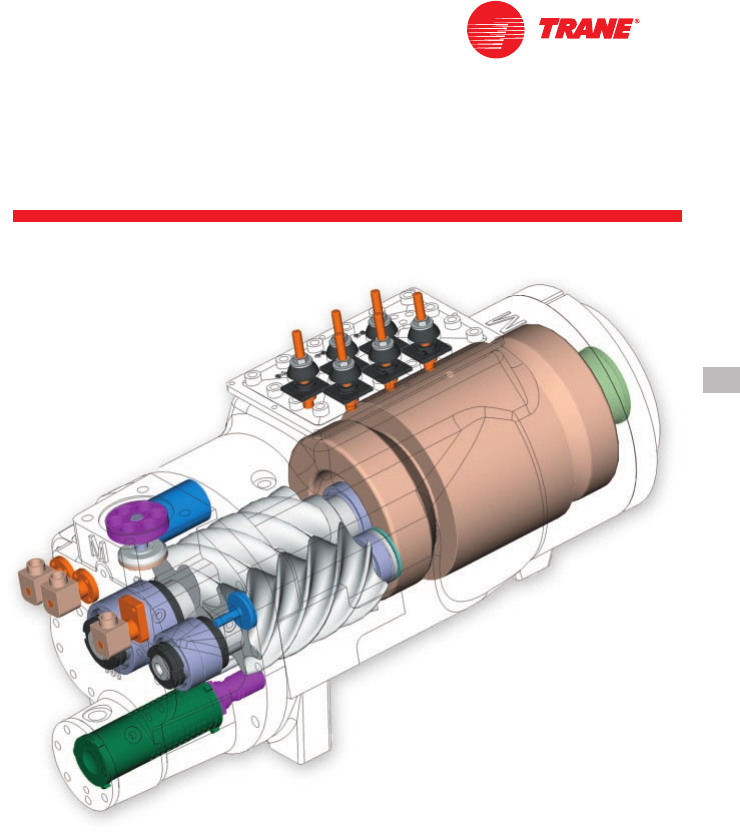

Figure 2 Cutaway of a compressor