– 6 –

WATER QUALITY STATEMENT

The fact that a water supply is potable is no guarantee that it is suitable for steam generation. Proper

water quality can improve the taste of the food prepared in the oven, reduce scale build-up or corrosion,

and extend equipment life. Local water conditions vary from one location to another and can change

throughout the year. The recommended water treatment for effective and effi cient use of this equipment

will vary depending on the local water conditions. Your water supply must be within the general guidelines

outlined in the chart below at all times during use of this machine or service issues not covered under

warranty may result.

Water hardness should be treated by removing the impurities (water softener with carbon block or de-

chlorinator and/or in-line water treatment). Low water hardness may also require a water treatment system

to reduce potential corrosion. Water treatment has been shown to reduce costs associated with machine

cleaning, reduce deliming and reduce corrosion of metallic surfaces.

Daily washing and rinsing of the cavity is required. In some cases it may be needed more than once a day

to prevent compounding of contaminants deposited inside cavity even with acceptable fi ltration. Failure

to wash and rinse down the cavity daily could result in damage of the oven cavity and interior parts. A

Reverse Osmosis water treatment system can be installed to eliminate chlorides or other contaminates

from the water if needed.

NOTE: Failure to properly maintain water quality or preventative procedures for water can lead to issues

not covered under warranty.

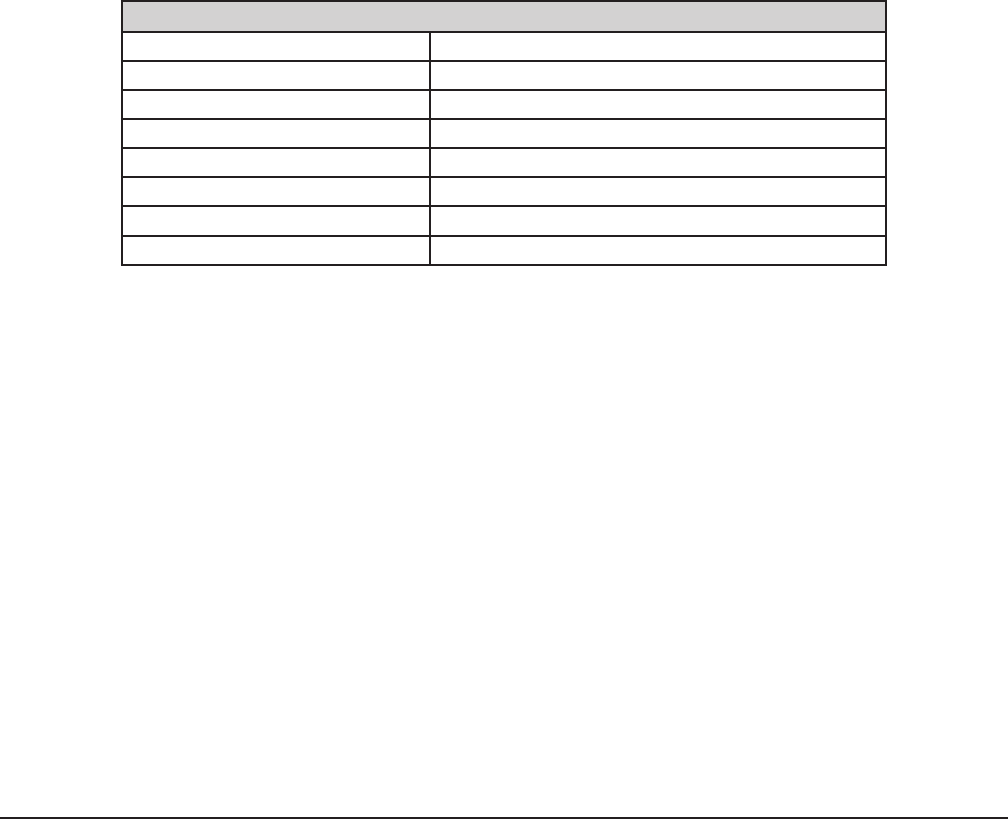

WATER SUPPLY GENERAL GUIDELINES*

Supply Pressure (dynamic fl ow) 30-60 psig

Hardness less than 3 grains (17.1 ppm = 1 grain of hardness)

Silica less than 13 ppm

Chloramines** zero

Chlorides** less than 30 ppm***

Total Chlorine**** zero

PH range 7-8

Un-Dissolved Solids less than 5 microns

* Testing of water is always done AFTER water fi lter or water treatment used. Water quality does change

with usage and should be checked after idle times to see if the condition worsens.

** A carbon block fi lter system should always be used to remove Chlorine and Chloramine. If a water

softener is used, a carbon block is still required. Check with your local water treatment specialist for proper

sizing and replacement intervals for the carbon block cartridge.

*** If the Chlorides exceed 30 ppm and the oven is used more than 8 hours during the day in steam or

combination mode the cavity will require rinsing every 8 hours. Failure to do so will result in corrosion and

rusting of the oven cavity and interior parts. A Reverse Osmosis water treatment system can be installed

to eliminate chlorides from the water and reduce the hardness. Preventative washing and rinsing may be

needed more than once a day to prevent compounding of contaminants inside cavity.

**** Total Chlorine of 4.0 ppm is the max limit for the building water supply. A carbon block fi lter must still

be used to remove all Chlorine and Chloramines from the water. Failure to do so will result in corrosion

and rust in the cooking cavity which is not covered under warranty.