Page 30

SERVICE (cont.)

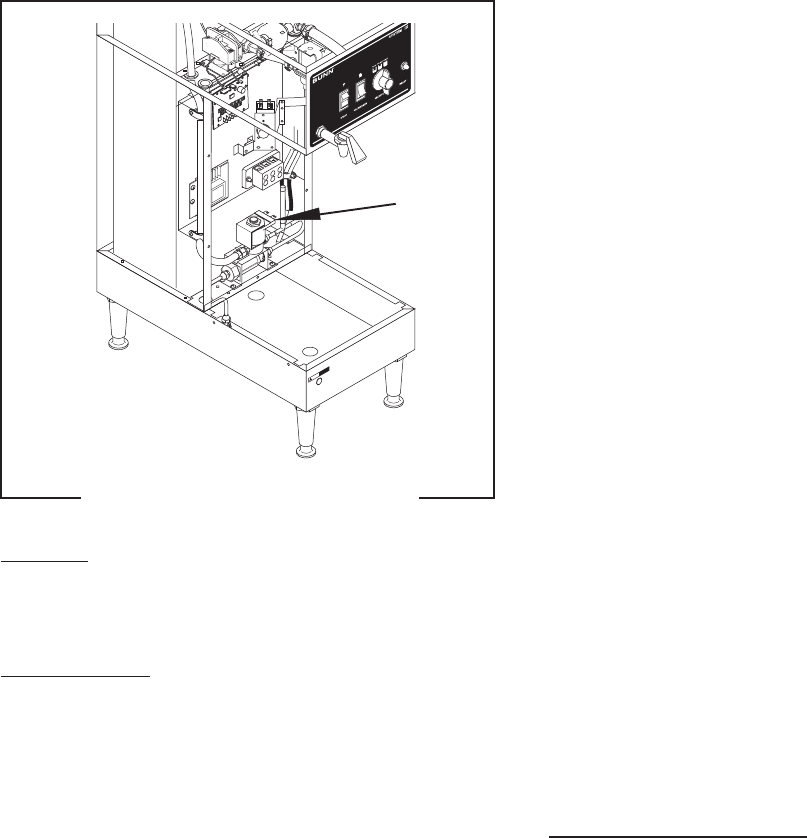

SOLENOID VALVE (Refill)

Location:

The inlet solenoid valve is located inside the trunk

on top of the flow control bracket.

Test Procedure:

1. Disconnect the brewer from the power source.

2. Disconnect both wires from the solenoid valve coil

terminals and check for continuity across the

solenoid valve coil terminals.

If continuity is present as described, reconnect the

white and violet wires on the electro/mechanical con-

trolled 120/208 and 120/240 volt brewers, white and

white/blue on DBC 120/208 and 120/240 volt brew-

ers, red and violet on electro/mechanical controlled

200 or 240 volt brewers and red and white/blue on

DBC 200 or 240 volt brewers.

If continuity is not present as described, replace the

solenoid valve.

3. With a voltmeter, check the voltage across the

solenoid valve terminal wires:

a.) White and violet wires on 120/208 and 120/

240 volt electro/mechanical controlled models.

b.) White and white/blue wires on 120/208 and

120/240 volt DBC models.

B

U

N

N

9

0

p

s

i

g

m

a

x

o

p

e

r

a

t

i

n

g

p

r

e

s

s

u

r

e

S

t

r

a

i

n

e

r

/

F

l

o

w

C

o

n

t

r

o

l

#

2

2

3

0

0

.

0

5

0

0

(

R

e

p

l

.

F

l

o

w

W

a

s

h

e

r

#2

0

5

2

6

.

0

5

0

0

)

(

R

e

p

l

.

S

c

r

e

e

n

#

2

3

7

2

1

.

0

0

0

0

)

.

5

0

0

g

p

m

F

L

O

W

!

C

A

U

T

IO

N

H

O

T

W

A

T

E

R

J2

SE

T

L

O

C

K

L

O

CK

SET

T

L

1

T

L

2

T

L

3

T

L

4

T

L

5

J

1

P2231.35

FIG. 23 REFILL SOLENOID VALVE

c.) Red and violet wires on 200 and 240V volt

electro/mechanical controlled models.

d.) Red and white/blue wires on 200 and 240 volt

DBC models.

Connect the brewer to the power source. The indica-

tion must be:

a.) 120 volts ac for three wire 120/208 volt mod-

els and three wire 120/240 volt models.

b.) 200 to 240 volts ac for two wire 200 or 240 volt

models.

4. Disconnect the brewer from the power source.

If voltage is present as described, proceed to #5.

If voltage is not present as described, refer to the

Wiring Diagrams

and check brewer wiring harness.

5. Check the solenoid valve for coil action. Connect

the brewer to the power source and draw water

from the faucet. Listen carefully in the vicinity of

the solenoid valve for a "clicking" sound after

approximately 1 second, as the coil magnet at-

tracts.

6. Disconnect the brewer from the power source.

If the sound is heard as described and water will not

pass through the solenoid valve, there may be a

blockage in the water line before or after the solenoid

valve or, the solenoid valve may require inspection for

wear, and removal of waterborne particles.

If the sound is not heard as described, replace the

solenoid valve.

Removal and Replacement:

1. Remove all wires from the solenoid valve coil.

2. Turn off the water supply to the brewer.

3. Disconnect the water lines to and from the sole-

noid valve.

4. Disconnect water line from the flow control to the

solenoid and remove.

5. Remove the four #8-32 screws securing the flow

control bracket to the support bracket and slide

bracket and solenoid over flow control.

6. Remove bracket and solenoid as an assembly.

7. Remove the two #10-32 screws and lockwashers

securing the solenoid valve to the flow control

bracket.

8. Using two #10-32 screws securely install the new

solenoid valve to the flow control bracket.

27362 092900