15

3. Remove the nuts that secure the terminal box transition

piece to the motor housing.

4. Disconnect the motor leads from the motor terminals

(Fig. 17). Note the position of the motor terminal cable

lugs so they can be reinstalled with sufficient clearance

away from surrounding structure.

5. Remove the motor temperature sensor leads (Fig. 17), the

motor ground lead, and the bolts that secure the VFD

enclosure to the terminal box transition piece.

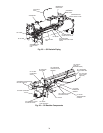

6. Disconnect the communication cables from the back of

the ICVC (Fig. 18).

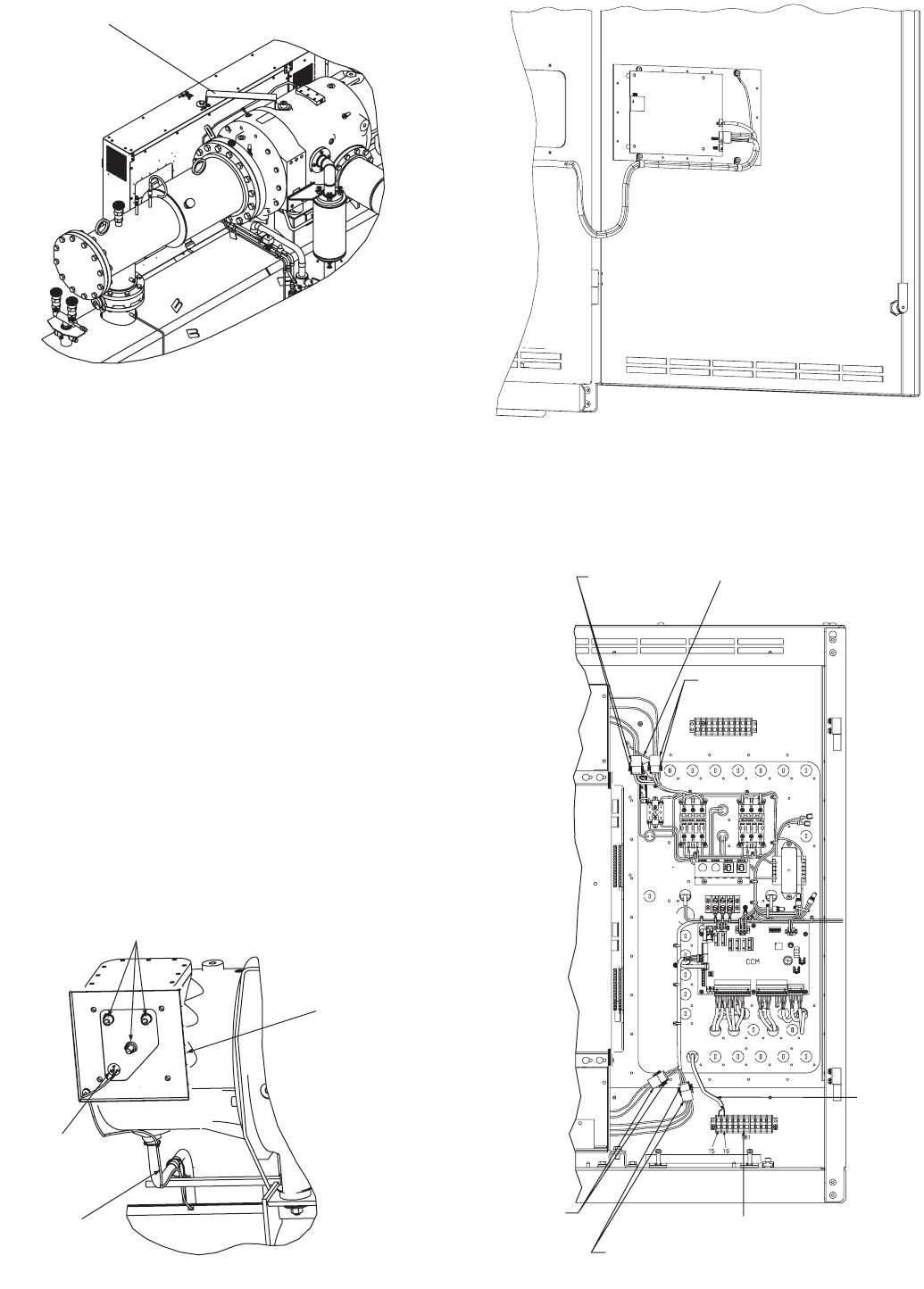

7. Disconnect the high pressure switch leads from terminal

strip TB1, terminals 15 and 16 (Fig. 19).

8. Unplug connectors CN1A, CN1B, CN2, and CN3

(Fig. 19).

9. Disconnect the control panel ground wire (Fig. 19) that is

located next to connectors CN1A and CN1B.

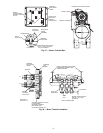

10. Disconnect the VFD cooling lines (Fig. 20) and cover all

openings.

11. Remove the 12 screws that secure the control panel to the

VFD enclosure. Tilt the control panel away from the back

of the control center.

12. Position the control panel on top of the condenser and

secure it in place to prevent damage.

SHIPPING

BRACKET

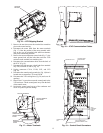

Fig. 16 — VFD Shipping Bracket

a23-1565

MOTOR TERMINAL

BOX FRAME

MOTOR

TEMPERATURE

CABLE

MOTOR

TEMPERATURE

SENSOR TERMINAL

BLOCK

MOTOR TERMINALS

Fig. 17 — Motor Terminals

a23-1566

Fig. 18 — ICVC Communication Cables

a23-1567

CONNECTOR CN1A

CONNECTOR CN1B

CONTROL PANEL

GROUND WIRE

CONNECTOR

CN2

CONNECTOR CN3

LOW VOLTAGE FIELD

WIRING TERMINAL STRIP

HIGH

PRESSURE

SWITCH

CABLE

Fig. 19 — Control Panel Connectors

a23-1570