35

NOTES FOR FIG. 44

GENERAL

1.0 Variable frequency drive (VFD) shall be designed and

manufactured in accordance with Carrier engineering

requirements.

1.1 All field-supplied conductors, devices and the field-

installation wiring, termination of conductors and devices,

must be in compliance with all applicable codes and job

specifications.

1.2 The routing of field-installed conduit and conductors and the

location of field-installed devices, must not interfere with

equipment access or the reading, adjusting or servicing of

any component.

1.3 Equipment installation and all starting and control devices,

must comply with details in equipment submittal drawings

and literature.

1.4 Contacts and switches are shown in the position they would

assume with the circuit de-energized and the chiller

shutdown.

1.5

POWER WIRING TO VFD

2.0 Provide a means of disconnecting branch feeder power to

VFD. Provide short circuit protection and interrupt capacity

for branch feeder in compliance with all applicable codes.

2.1 If metal conduit is used for the power wires, the last 4 feet or

greater should be flexible to avoid transmitting unit vibration

into the power lines and to aid in serviceability.

2.2 Line side power conductor rating must meet VFD nameplate

voltage and chiller minimum circuit ampacity.

2.3 Lug adapters may be required if installation conditions

dictate that conductors be sized beyond the minimum

ampacity required. Circuit breaker lugs will accommodate

the quantity (#) and size cables (per phase) as shown in

Table 12.

2.4 Compressor motor and controls must be grounded by using

equipment grounding lug provided inside unit mounted VFD

enclosure.

CONTROL WIRING

3.0 Field-supplied control conductors to be at least 18 AWG or

larger.

3.1 Ice build start/terminate device contacts, remote start/stop

device contacts and spare safety device contacts, (devices

not supplied by Carrier), must have 24 VAC rating. Max cur-

rent is 60 mA, nominal current is 10 mA. Switches with gold

plated bifurcated contacts are recommended.

3.2 Remove jumper wire between TB1-19 and TB1-20 before

connecting auxiliary safeties between these terminals.

3.3 Each integrated contact output can control loads (VA) for

evaporator pump, condenser pump, tower fan low, tower fan

high, and alarm annunciator devices rated 5 amps at

115 VAC and up to 3 amps at 277 VAC.

Do not use control transformers in the control center as the

power source for external or field-supplied contactor coils,

actuator motors or any other loads.

3.4 Do not route control wiring carrying 30 V or less within a

conduit or tray which has wires carrying 50 V or higher or

along side wires carrying 50 V or higher.

3.5 Spare 4-20 mA output signal is designed for controllers with

a non-grounded 4-20 mA input signal and a maximum input

impedance of 500 ohms.

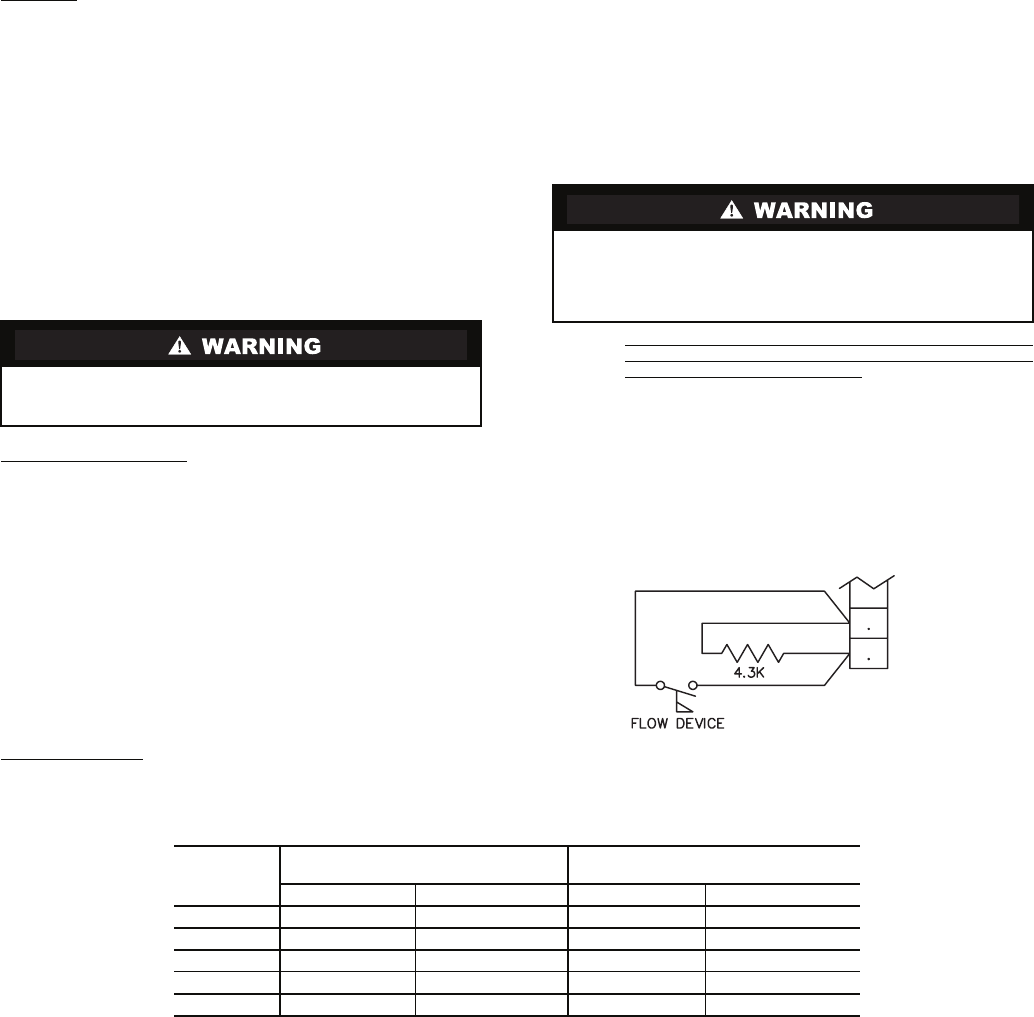

3.6 Flow devices to confirm evaporator or condenser pump flow

are not required. However; if flow devices are used, wire as

shown on drawing 23XRC1-1 (J3 lower). Remove jumper

installed at these terminals and wire in a 4.3 K resistor in its

place.

The flow device and resistor must be installed in parallel at

these terminals such that the resistor provides a signal when

the flow device is open.

Table 12 — Lug Capacity

NOTE: If larger lugs are required, they can be purchased from the manufacturer of the circuit

breaker (Cutler-Hammer or Square D).

Do not use aluminum conductors. Contractor/installer assumes all

liability resulting from the use of aluminum conductors within the

VFD enclosure.

Control wiring required for Carrier to start pumps and tower fan

motors and establish flows must be provided to assure machine

protection. If primary pump, tower fan and flow control is by other

means, also provide a parallel means for control by Carrier. Failure

to do so could result in machine freeze-up or over-pressure.

CCM

J3 (LOWER)

a23-1587

VFD

MAX. INPUT

AMPS.

STANDARD 65K AIC LUG CAPACITY

(PER PHASE)

OPTIONAL 100K AIC LUG CAPACITY

(PER PHASE)

No. Conductors Conductor Range No. Conductors Conductor Range

225A 3 3/0 — 500MCM 2 3/0 — 250MCM

338A 3 3/0 — 500MCM 2 400 — 500MCM

440A 3 3/0 — 500MCM 2 400 — 500MCM

520A 3 3/0 — 500MCM 3 3/0 — 400MCM

608A 3 3/0 — 500MCM 3 3/0 — 400MCM