2

CONTENTS

Page

SAFETY CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . 1

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Job Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-42

Receiving the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

• INSPECT SHIPMENT

• IDENTIFY MACHINE

• INSTALLATION REQUIREMENTS

• PROVIDE MACHINE PROTECTION

Rigging the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

• RIG MACHINE ASSEMBLY

• RIG MACHINE COMPONENTS

Separate Machine Components . . . . . . . . . . . . . . . . . 13

• SEPARATE COOLER AND CONDENSER

• REMOVE THE CONTROLS/DRIVE ENCLOSURE

FROM THE CONDENSER

• REMOVE THE DISCHARGE PIPE ASSEMBLY

FROM THE CONDENSER

• SEPARATE THE COMPRESSOR FROM THE

CONDENSER

• SEPARATE THE VAPORIZER FROM THE

CONDENSER

VFD Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Install Machine Supports . . . . . . . . . . . . . . . . . . . . . . . . 22

• INSTALL STANDARD ISOLATION

• INSTALL ACCESSORY ISOLATION

• INSTALL SPRING ISOLATION

Connect Piping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

• INSTALL WATER PIPING TO HEAT

EXCHANGERS

• INSTALL VENT PIPING TO RELIEF VALVES

Make Electrical Connections . . . . . . . . . . . . . . . . . . . . 30

• GROUNDING THE CONTROLS/DRIVE

ENCLOSURE

• INSTALLING INPUT POWER WIRING

• WIRING THE FIELD WIRING TERMINAL STRIPS

• CONNECT CONTROL INPUTS

• CONNECT CONTROL OUTPUTS

• CONNECT STARTER

COMPLETING THE INSTALLATION . . . . . . . . . . . 43-47

Checking the Installation . . . . . . . . . . . . . . . . . . . . . . . . 43

Oil Pump and Oil Heater . . . . . . . . . . . . . . . . . . . . . . . . . 43

Connect Control Wiring . . . . . . . . . . . . . . . . . . . . . . . . . 43

Carrier Comfort Network Interface. . . . . . . . . . . . . . . 43

Lead-Lag Control Wiring . . . . . . . . . . . . . . . . . . . . . . . . 44

Install Field Insulation and Lagging . . . . . . . . . . . . . 44

INSTALLATION START-UP REQUEST

CHECKLIST . . . . . . . . . . . . . . . . . . . . . . . . . . . CL-1, CL-2

INTRODUCTION

General —

The 23XRV machine is factory assembled,

wired, and leak tested. Installation (not by Carrier) consists

primarily of establishing water and electrical services to the

machine. The rigging, installation, field wiring, field piping,

and insulation of waterbox covers are the responsibility of the

contractor and/or customer. Carrier has no installation respon-

sibilities for the equipment.

Job Data — Necessary information consists of:

• job contract or specifications

• machine location prints

• rigging information

• piping prints and details

• field wiring drawings

• starter manufacturer’s installation details

• Carrier certified print

INSTALLATION

Receiving the Machine

INSPECT SHIPMENT

1. Inspect for shipping damage while machine is still on ship-

ping conveyance. If machine appears to be damaged or

has been torn loose from its anchorage, have it examined

by transportation inspectors before removal. Forward

claim papers directly to transportation company. Manufac-

turer is not responsible for any damage incurred in transit.

2. Check all items against shipping list. Immediately notify

the nearest Carrier representative if any item is missing.

3. To prevent loss or damage, leave all parts in original pack-

ages until beginning installation. All openings are closed

with covers or plugs to prevent dirt and debris from enter-

ing machine components during shipping. A full operating

oil charge is placed in the oil sump before shipment.

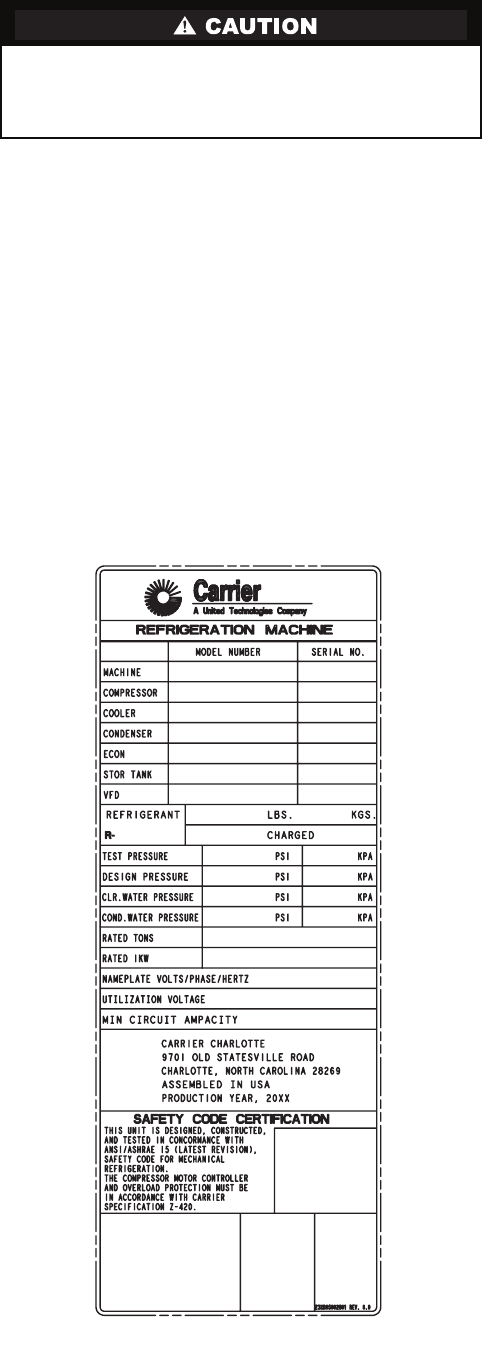

IDENTIFY MACHINE (Fig. 1-4) — Refer to machine name-

plate in Fig. 1. The machine model number, serial number, and

heat exchanger sizes are stamped on the Refrigeration Machine

nameplate located on the side of the VFD (variable frequency

drive) enclosure. Check this information against shipping

papers and job data.

Do not open any valves or loosen any connections. The

23XRV machine may be shipped with a full refrigerant

charge. Some machines may be shipped with a nitrogen

holding charge as an option.

Fig. 1 — Refrigeration Machine Nameplate

a23-1547