22

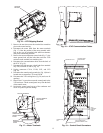

Insulate Motor Terminals and Lead Wire Ends — Locate

heat shrink tubing (RCD P/N LF33MM114) over power

connections so that they are completely covered and

tubing is against motor housing. Shrink into position.

Slide foam tubing (3 in. inner diameter closed cell vinyl,

neoprene, or nitrile foam) part way over the heat shrink

tubing. Apply adhesive for closed cell foam insulation to

motor side end of the foam tubing and push tubing the

rest of the way over the terminal and against the sheet

insulation on the motor side. Secure the opposite end of

the foam tubing with a wire tie as shown in Fig. 28.

Alternate Insulation for Motor Terminals and Lead Wire

Ends — Insulate compressor motor terminals, lead wire

ends, and electrical wires to prevent moisture condensa-

tion and electrical arcing. Obtain Carrier approved insula-

tion material from RCD (Replacement Components

Division) consisting of 3 rolls of insulation putty and one

roll of vinyl tape.

a. Insulate each terminal by wrapping with one layer

of insulation putty (RCD P/N 19EA411-1102).

b. Overwrap putty with 4 layers of vinyl tape.

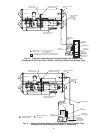

6. Orient PE/ground lug as shown in Fig. 28. Assemble

internal/external tooth lock washer between the terminal

box frame and the PE/ground cable. Torque PE/ground

lug nut to 55 to 65 ft-lb (75 to 89 N-m). See section H-H

in Fig. 29 for PE/ground cable routing.

7. Center terminal enclosure frame over terminal box frame

assembly so the space between the frames is equal within

3

/

16

-in. (5 mm) at the top and bottom. Use the slots in the

terminal enclosure frame. Adjust spacing between the

sides of the terminal enclosure frame and terminal box

frame assemblies by moving the control center to the left

or right.

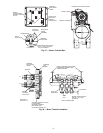

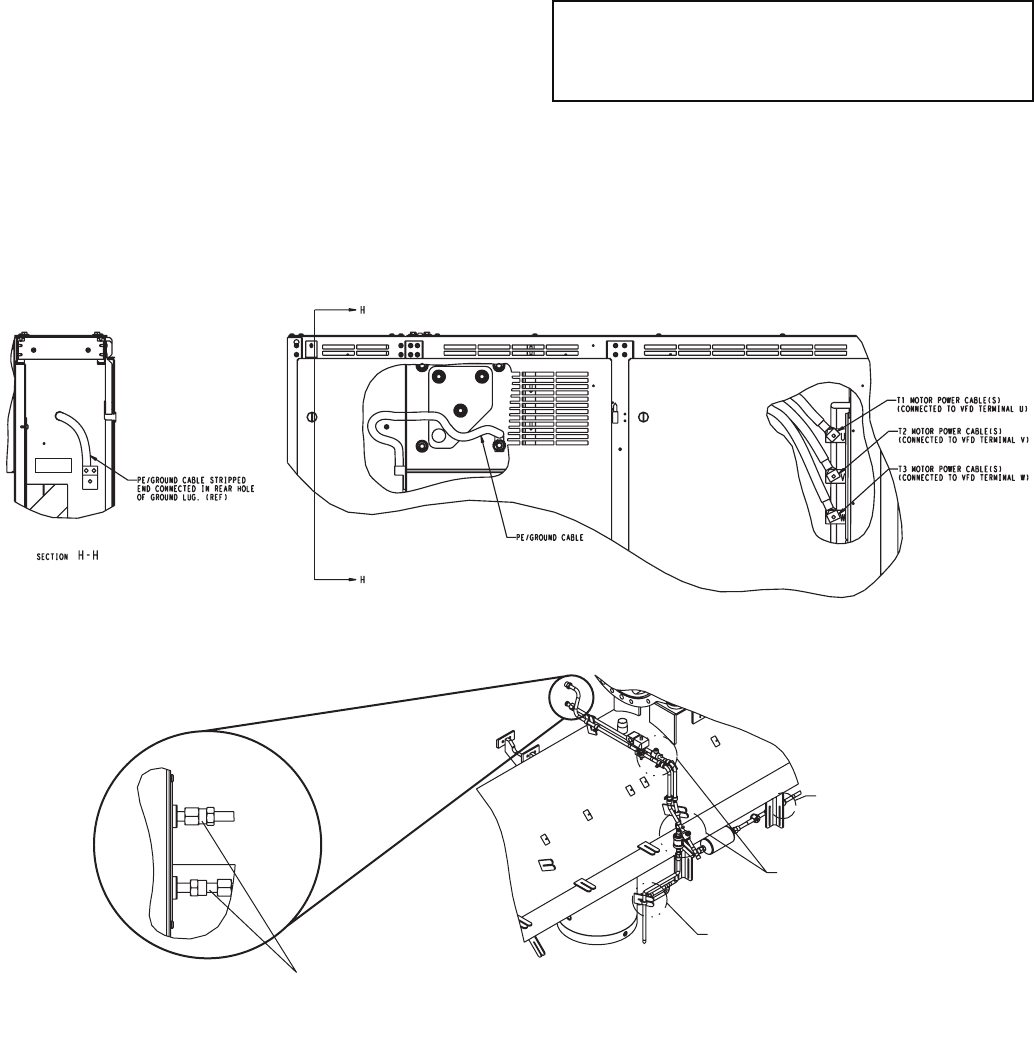

8. Install O-rings on VFD refrigerant connections using

silicone grease. Tighten connector using two wrenches to

27 to 33 ft-lb (37 to 45 N-m). (See Detail A in Fig. 30.)

9. Evacuate all piping between the VFD and the VFD isola-

tion valves after assembly and tightening of VFD fittings.

Dehydration/evacuation is complete to equalize VFD

piping pressure with machine pressure if machine is

charged with refrigerant (see Fig. 30).

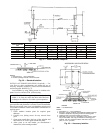

Install Machine Supports

INSTALL STANDARD ISOLATION — Figures 31 and 32

show the position of support plates and shear flex pads, which

together form the standard machine support system.

Service clearance under the chiller can be enhanced if the

grout is not extended along the entire length of the heat

exchangers.

IMPORTANT: Chiller housekeeping pad, anchor

bolts and attachment points to be designed by others in

accordance with all applicable national and local

codes.

VFD COOLING

LINE O-RING

FACE SEAL

COUPLINGS

DETAIL A

SEE

DETAIL A

FILTER DRIER

ISOLATION VALVE

VFD ISOLATION

VALVES (2)

FILTER DRIER

ISOLATION VALVE

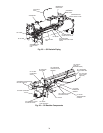

Fig. 29 — Motor Ground Cable

Fig. 30 — VFD Refrigerant Connectors

a23-1578

a23-1579