31

Table 11 — Relief Valve Locations

NOTE: All valves relieve at 185 psi (1275 kPa).

These instructions are intended for qualified electrical per-

sonnel familiar with servicing and installing AC drives. Any

questions or problems with the products described in this man-

ual should be directed to your local Carrier Service Office.

Wiring diagrams in this publication are for reference only

and are not intended for use during actual installation; follow

job specific wiring diagrams.

GROUNDING THE CONTROLS/DRIVE ENCLOSURE —

Use the following steps to ground the drive.

1. Open the left door of the control center.

2. Run a suitable equipment grounding conductor unbroken

from the drive to earth ground. Tighten these grounding

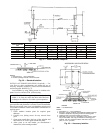

connections to the proper torque. See Fig. 6 and 29.

3. Close the door to the control center.

INSTALLING INPUT POWER WIRING — All wiring should

be installed in conformance with the applicable local, national,

and international codes (e.g., NEC/CEC). Signal wiring, control

wiring, and power wiring must be routed in separate conduits to

prevent interference with the drive operation. Use grommets,

when hubs are not provided, to guard against wire chafing.

Use the following steps to connect AC input power to the

main input circuit breaker:

1. Turn off, lock out, and tag the input power to the drive.

2. Remove the input power wiring panel above the VFD

circuit breaker and drill the number of openings for the

AC input leads (refer to Fig. 6). Mount all conduit hard-

ware on the input power wiring panel before re-installing

the input power wiring panel on the VFD enclosure.

Take care that metal chips and hardware do not enter the

enclosure.

3. Wire the AC input leads by routing them through the

openings in the input power wiring panel.

4. Connect the three-phase AC input power leads (per job

specifications) to the appropriate input terminals of the

circuit breaker. See Fig. 6.

5. Tighten the AC input power terminals and lugs to the

proper torque as specified on the input circuit breaker.

LOCATION

FRAME

SIZE

RELIEF VALVE OUTLET SIZE

QUANTITY WITHOUT

ISOLATION VALVES

QUANTITY WITH

ISOLATION VALVES

Discharge Pipe Assembly 3-5 1

1

/

4

-in. NPT FEMALE CONNECTOR 0 1

Cooler 3-5 1

1

/

4

-in. NPT FEMALE CONNECTOR 2 1

Condenser 3-5 1

1

/

4

-in. NPT FEMALE CONNECTOR 2 2

Optional Storage Tank N/A 1-in. NPT FEMALE CONNECTOR 2 2

DC bus capacitors in the VFD retain hazardous voltages

after input power has been disconnected. After disconnect-

ing input power, wait 5 minutes for the DC bus capacitors

to discharge then check both the VFD DPI Communica-

tions Interface Board Status LEDs and the VFD with a

voltmeter to ensure the DC bus capacitors are discharged

before touching any internal components. Failure to

observe this precaution could result in severe bodily injury

or loss of life.

The drive can operate at and maintain zero speed. The user

is responsible for assuring safe conditions for operating

personnel by providing suitable guards, audible or visual

alarms, or other devices to indicate that the drive is operat-

ing or may operate at or near zero speed. Failure to observe

this precaution could result in severe bodily injury or loss

of life.

Do not install modification kits with power applied to the

drive. Disconnect and lockout incoming power before

attempting such installation or removal. Failure to observe

this precaution could result in severe bodily injury or loss

of life.

The drive contains ESD (Electrostatic Discharge) sensitive

parts and assemblies. Static control precautions are

required when installing, testing, servicing, or repairing the

drive. Erratic machine operation and damage to, or destruc-

tion of, equipment can result if this procedure is not

followed. Failure to observe this precaution could result in

bodily injury.

The user is responsible for conforming with all applicable

local, national and international codes. Failure to observe

this precaution could result in damage to, or destruction of,

the equipment.

Do not attempt to start compressor (even for a rotation

check) or apply test voltage of any kind while machine is

under dehydration vacuum. Motor insulation breakdown

and serious damage may result.

Low oil level may result if the oil pump is manually oper-

ated for more than a few minutes when the chiller is not

running. The oil reclaim system does not return oil to the

sump when the compressor is de-energized.

Do not route signal and control wiring with power wiring

in the same conduit. This can cause interference with con-

trol and drive operation. Failure to observe this precaution

could result in damage to, or destruction of, the equipment.