OV500 SERIES RACK OVEN - SERVICE PROCEDURES AND ADJUSTMENTS

IGNITION MODULE SELF

DIAGNOSTICS

Ignition module makes three attempts to light burner

before proceeding to lock-out mode.

1. Turn oven on and set controller to call for heat.

2. Access the ignition module by removing

component panel cover.

3. Check ignition module indicator LED for fault

codes as stated in following chart.

NOTE: LED will briefly illuminate during pre-purge.

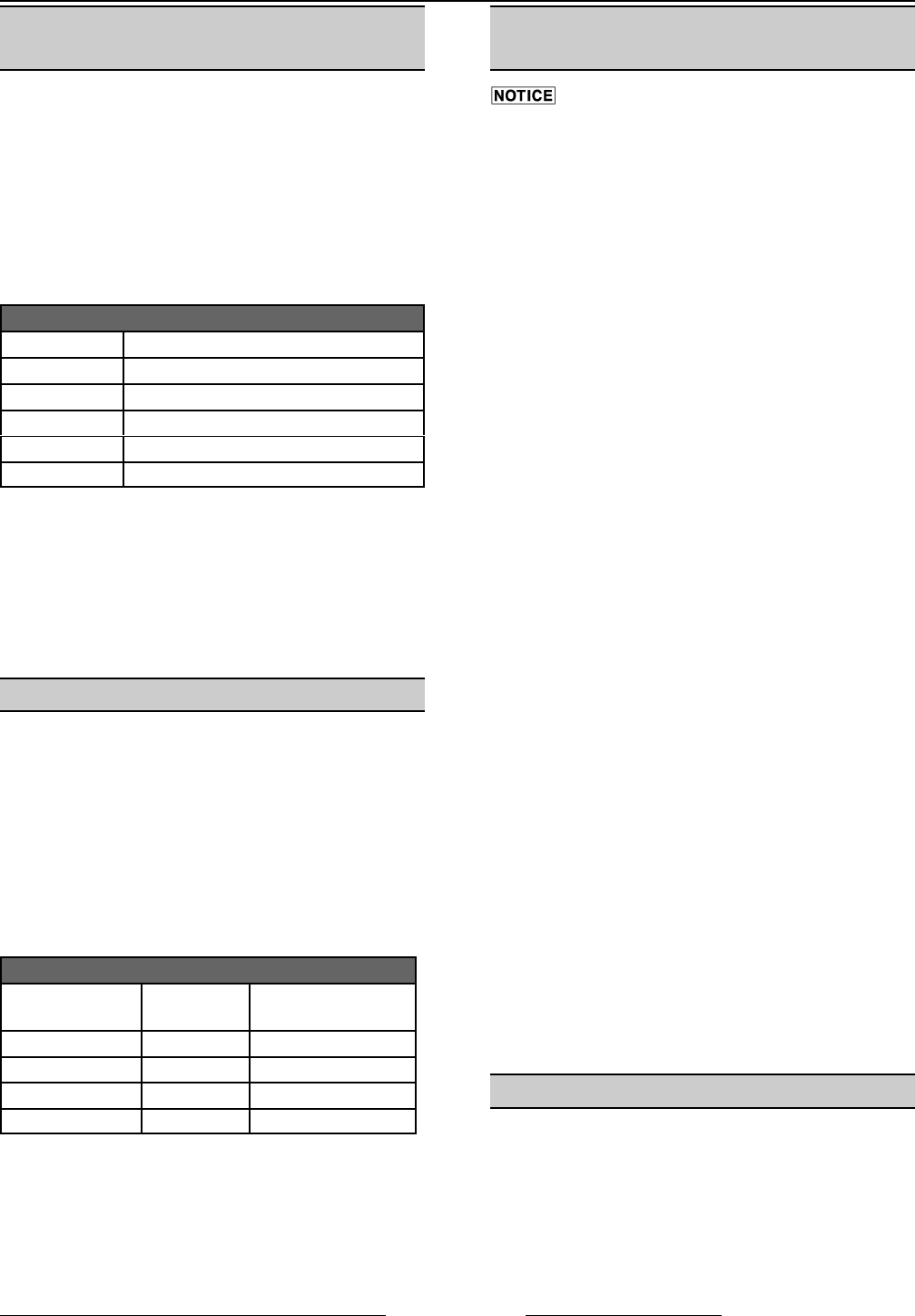

LED DIAGNOSTIC INDICATOR CODES

LED CODES

LED off No Fault

LED on Control Fault

'1' Flash Air Flow Fault

'2' Flash Flame No Call For Heat*

'3' Flash Ignition Lockout

* Flame continues after controller set temperature is

satisfied. (Gas valve sticks open.)

4. Disconnect power to oven.

5. Correct the fault.

6. Re-apply power.

7. Check ignition module for correct operation.

TEMPERATURE PROBE TEST

1. Access controller board.

2. Disconnect temperature probe lead wires from

controller board.

3. Set the multi meter to milli volt scale and

connect positive lead (red) to the (white) probe

lead wire and negative lead (black) to (red)

probe lead wire.

4. Verify the multi meter reading to the

temperature conversion chart as follows.

TEMPERATURE CONVERSION CHART

FAHRENHEIT CELSIUS

MILLIVOLT

RANGE

100 38 -1.8 to 1.2

200 93 1.5 to 4.3

300 149 4.5 to 7.3

400 204 7.5 to 10.6

5. If multi meter reading indicates an open or is

outside the millivolt range, replace the

temperature probe as outlined under

TEMPERATURE PROBE.

CONTROLLER TEMPERATURE

CALIBRATION

Certain components in this system are

subject to damage by electrostatic discharge during

field repairs. A field service grounding kit is available

to prevent damage. The field service grounding kit

must be used anytime the control board is handled.

1. Check setting of controller temperature offset

(P4) as outlined under CONTROLLER

DEFAULT SETTINGS and record setting.

2. Verify that the probe is functioning properly as

outlined under TEMPERATURE PROBE TEST.

3. Place a thermocouple of a temperature tester in

the center of right incoming air slot of the bake

chamber.

A. Route thermocouple through hinge side of

door to the outside of the oven. Make sure

that the lead wire is kept clear of the rack

carrier.

4. Turn the oven on.

5. Set the controller temperature to 400EF.

6. Allow the oven temperature to stabilize

(minimum 3 cycles).

7. Note temperature reading on temperature tester

and controller at the exact time the heat light on

the controller goes out.

8. If the temperature difference between the two

readings is greater than ±2EF or ±1EC, adjust

the temperature offset (P4) as outlined under

CONTROLLER DEFAULT SETTINGS.

A. If temperature test shows a temperature

higher than controller, increase offset (P4)

the amount of difference.

B. If temperature test shows a temperature

lower than controller, decrease offset (P4)

the amount of difference.

C. If temperature difference is greater than

the range of the controller, replace

controller (range ±50EF. or ±10EC.).

9. Check for proper operation.

10. Remove temperature tester thermocouple from

the oven.

CONTROLLER SETTINGS

CLOCK SETTING

1. Press the Power On/Off keypad to turn the

oven on.

2. Press and hold either Auto On/Off Timer

Up/Down Arrows for 3 seconds.

3. After the colon stops flashing use the Up/Down

Arrows to adjust the clock setting.

F25361 (January 2010)

Page 29 of 60