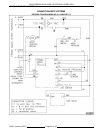

OV500 SERIES RACK OVEN - ELECTRICAL OPERATION

1) CR4 de-energized.

2) Door input removed from control board

(A2 not lit).

3) Circuit to rotator motor continues thru

CR4 N.C.

D. Rack continues to rotate until rack pointer

operates rack position switch #1 and #2.

(Rack centered in door).

NOTE: In some instances when the door is opened,

the rack may be centered in door. CR3 will energize.

Rack will stay centered in door and then lower.

E. Rack position switch #2 N.O. contacts

close.

F. Rack position switch #1 N.O. contacts

close. Input signals control board that rack

is centered in door for the first time since

stop button was pushed and door was

opened.CR3 energized thru rack position

switch #1 N.O. contacts. Latching circuit

keeps CR3 energized if rack would coast

past pointer.

1) CR3 N.C. contacts open and rotator

motor M4 de-energized.

2) CR3 N.O. contacts close and lift motor

is energized thru LS2 N.C. contacts,

lowering the rack.

3) As the rack starts to lower LS1 N.O.

contacts open and LS1 N.C. contacts

close.

13. When rack is completely lowered, LS2 N.C.

contacts open and LS2 N.O. contacts close.

Lift motor is de-energized.

14. Remove rack.

15. Shut door and oven will continue to maintain

set temperature (preheat mode). The rack lift

will remain in load/unload position and not

rotate.

BURNER SEQUENCE OF

OPERATION

1. Power (24VAC) to ignition module L1 and R -

(A4 lit).

2. 24VAC output from control (A8 lit) to ignition

module terminal W and one side of the draft

inducer pressure switch.

A. Draft inducer motor energized from ignition

module terminal F2 (115VAC).

B. Inducer pressure switch closes.

1) Power to terminal PS.

3. Pre-Purge cycle begins (15 seconds).

4. Ignition module energizes hot surface ignitor

(24VAC) thru terminal S1 for 4 second heat up

time.

5. Gas valve energized thru MV1 two seconds

after start of hot surface ignitor cycle.

6. Top burner lights and flame spreads to all

burners.

7. Flame sensor rod is engulfed in flame and a

current is rectified between the flame and

ground thru the sensor. Ignition module

requires a steady 1.0 microamp to verify flame

presence.

NOTE: Ignition module makes three attempts to

achieve ignition. 30 seconds inter-purge between

each attempt. If after the three tries for ignition and

the burner has not lit, there will be an additional 15

seconds purge time. After which the ignition module

will enter a lock-out condition. The ignition module

utilizes a 3 blink code of the LED for this problem.

The ignition module will have to be reset by

removing power from the ignition module. To do this,

open the door or cycle the main circuit breaker

(110VAC) to the oven.

8. When set temperature is met, control removes

heat output to ignition module terminal W (A8

not lit).

A. Ignition module is de-energized.

1) Gas valve de-energized.

2) Draft inducer motor M3 de-energized

30 seconds after gas valve de-

energized.

B. Inducer pressure switch N.O. contacts

open.

F25361 (January 2010)

Page 50 of 60