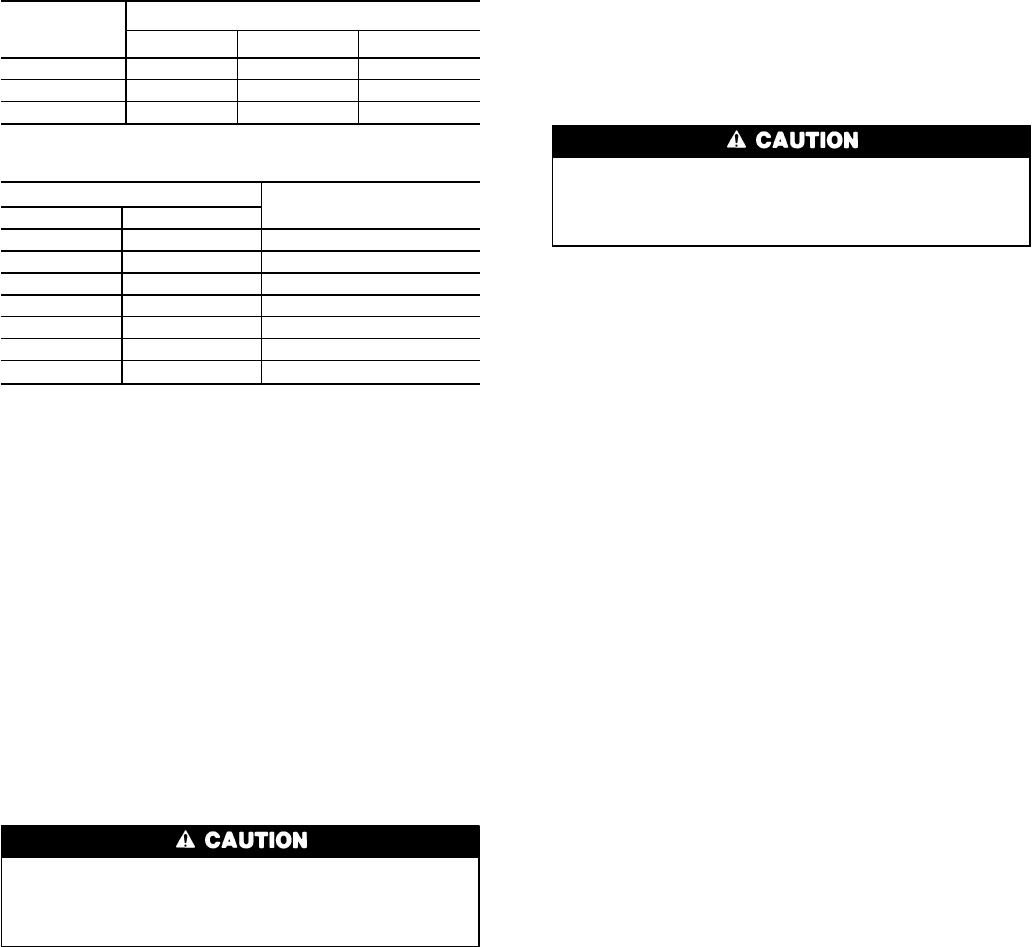

Table5—Typical Deadband Requirements

UNIT

CAPACITY

STEPS

COOLER DESIGN RANGE, F (C)

5.0 (2.8) 10.0 (5.6) 15.0 (8.3)

2 1.3 (0.7) 2.5 (1.4) 3.8 (2.1)

3 0.8 (0.4) 1.7 (0.9) 2.5 (1.4)

4 0.6 (0.3) 1.3 (0.7) 1.9 (1.1)

Table 6 — Deadband Setting

MIN. REQUIRED DEADBAND

DEADBAND SETTING (F)

FC

0.5 to 1.5 0.28 to 0.83 1.0

2.0 1.11 2.0

2.5 1.39 2.5

3.0 1.67 2.8

3.5 1.94 3.0

4.0 2.22 3.7

4.5 2.50 4.0

10. Check compressor oil charge (should be visible in

oil sight glass). Refer to Check Oil Charge section on

page 27.

11. Be sure the compressor crankcase heater is warm (heater

should be on for 24 hours before starting the compres-

sor). The crankcase heater must be firmly locked into

the compressor crankcase.

12. Be sure the compressor is floating freely on the com-

pressor springs (see Step 4 — Check Compressor Mount-

ing and Connections section on page 3).

13. For 30HL and HWA units with remote condenser, check

the condenser fans for correct rotation. See instructions

shipped with the condenser.

14. Be sure the unit is fully charged with refrigerant (see

Check Refrigerant Charge section below).

15. If unit is a brine unit, check to ensure proper brine con-

centration is used to prevent freezing.

Check Refrigerant Charge

When adding or removing refrigerant charge, circulate

water through condenser and cooler at all times to pre-

vent freezing. Freezing damage is considered abuse and

is not covered by Carrier warranty.

The 30HK, HWB, HWC, and HWS units are shipped with

a full refrigerant charge (see Tables 1A-2B). However, if it

is necessary to add refrigerant, operate the unit for some time

at full capacity and then add charge until the sight glass is

clear of bubbles. For maximum liquid subcooling, liquid level

should be up to condenser end (30HK, HWC, HWS units

only). This usually requires additional refrigerant charge be-

yond the amount to clear sight glass.

The 30HL and HWAunits (condenserless) are shipped with

a refrigerant holding charge only. After chiller assembly is

completed in the field, system must be fully charged. While

the unit is running at full capacity, add refrigerant until the

sight glass is clear. R-22 is the normal refrigerant.

Do not open the liquid valve or the compressor discharge

valve until there is a charge in remainder of system. A posi-

tive pressure indicates a charge in system. With the unit op-

erating at full load, check liquid line sight glass to be sure

the unit is fully charged (bubbles in the sight glass indicate

the unit is not fully charged).

If there is no refrigerant vapor pressure in the system, the

entire system must be leak tested.After repairing leaks, evacu-

ate the system before recharging. Follow approved evacu-

ation procedures when removing refrigeration. Release re-

maining pressure to an approved evacuated cylinder.

The liquid charging method is recommended for com-

plete charging or when additional charge is required.

Be careful not to overcharge the system. Overcharging

results in higher discharge pressure with higher cooling

water consumption, possible compressor damage, and

higher power consumption.

LIQUID CHARGING METHOD — Add charge to the unit

through the liquid line service valve. Never charge liquid

into the low-pressure side of the system.

1. Frontseat (close) condenser liquid line shutoff valve.

2. Connect a refrigerant cylinder loosely to the charging valve

connection of the liquid line shutoff valve. Purge the charg-

ing hose and tighten the connections.

3. Open the charging valve.

4. If the system has been dehydrated and is under vacuum,

break the vacuum with refrigerant gas. For R-22, build

up system pressure to 58 psig and 32 F (400 kPa and

0° C). Invert the refrigerant cylinder so that the liquid

refrigerant will be charged.

5. a. For complete charge of 30HK, HWB, HWC, and HWS

units, follow charging by weight procedure.When charge

is nearly full, complete the process by observing the

sight glass for clear liquid flow. The use of sight glass

charging is valid only when unit is operating at full

capacity (no unloaders energized).

b. For complete charge of 30HLand HWA units or where

refrigerant cylinder cannot be weighed, follow charg-

ing by sight glass procedure. The use of sight glass

charging is valid only when unit is operating at full

capacity (no unloaders energized).

6. a. The 30HL and HWA condenserless units are shipped

with a holding charge only. After installation with the

field-supplied system high side, the complete system

should be charged until the sight glass is clear (with

the unit running at full capacity). To achieve maxi-

mum system capacity, add additional charge equal to

the difference between the condenser optimal charge

and the condenser minimum charge, which can be ob-

tained from the charge data provided in the condenser

installation instructions.

b. To ensure maximum performance of 30HWB units,

raise the compressor saturated discharge temperature

(SDT) to approximately 105 F (40.6 C) by throttling

the condenser water intake. Add charge until there is

approximately 15 to 17° F (8.3 to 9.4° C) of system

subcooling (SDT minus actual temperature entering the

thermostatic expansion valve).

c. To ensure maximum performance of 30HK, HWC, and

HWS units, raise the compressor saturated discharge

temperature (SDT) to approximately 103 F (39.4 C)

by throttling the condenser water intake. Add charge

until there is approximately 8 to 10° F (4.4 to 5.6° C)

for 30HK units or 12 to 14° F (6.7 to 7.8° C) for 30HWC,

HWS units of system subcooling (SDT minus actual

temperature entering the thermostatic expansion valve).

26