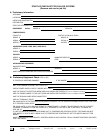

B. Preliminary Equipment Check (YES or NO) (cont)

HAVE POWER SIDE ELECTRICAL COMPONENT CONNECTIONS BEEN CHECKED FOR TIGHTNESS?

ON 30HK,HL UNITS, IS THE PROPER CONTROL VOLTAGE SUPPLIED TO TB2-1 AND TB2-3?

ON 30HK,HL50 HZ UNITS, IS THE BLACK WIRE GOING TO TRAN1 AND TRAN2 CONNECTED TO THE RED LEAD FROM

THE TRANSFORMER?

CHECK AIR SYSTEMS (YES OR NO)

ARE ALL AIR HANDLERS OPERATING?

(refer to air-handling equipment Installation and Start-Up Instructions)

ARE ALL CHILLED FLUID VALVES OPEN?

IS THE FLUID PIPING CONNECTED PROPERLY?

HAS ALL AIR BEEN VENTED FROM THE COOLER LOOP?

IS THE CHILLED WATER (FLUID) PUMP (CWP) OPERATING?

IS THE CWP ROTATION CORRECT?

CWP MOTOR AMPERAGE: Rated

Actual

C. Unit Start-Up (insert check mark as each item is completed)

HAS THE CHILLER BEEN PROPERLY INTERLOCKED WITH THE AUXILIARY CONTACTS OF THE CONDENSER

WATER PUMP STARTER?

ASSURE THAT UNIT IS SUPPLIED WITH CORRECT CONTROL VOLTAGE POWER.

ASSURE CRANKCASE HEATERS HAVE BEEN ENERGIZED FOR A MINIMUM OF 24 HOURS PRIOR TO

START-UP.

ASSURE COMPRESSOR OIL LEVEL IS CORRECT.

ASSURE LIQUID LINE SERVICE VALVE(S) IS BACKSEATED.

ASSURE COMPRESSOR DISCHARGE SERVICE VALVE(S) IS BACKSEATED.

ASSURE COMPRESSOR SUCTION SERVICE VALVE(S) IS BACKSEATED.

LOOSEN COMPRESSOR SHIPPING ISOLATOR LOCKNUTS.

OPEN GAGE PANEL SERVICE VALVES.

BE SURE TEMPERATURE CONTROLLER DEADBAND AND SAMPLE RATE SETTINGS ARE SET.

SET POINT SHOULD BE ADJUSTED TO THE DESIRED COOLER LEAVING FLUID TEMPERATURE. (refer to installation

instructions)

LEAK CHECK THOROUGHLY: COMPRESSOR(S), CONDENSER FITTINGS, TXV(s), SOLENOID VALVE(S), FILTER

DRIER(S), FUSIBLE PLUG(S), AND COOLER HEAD(S), WITH GENERAL ELECTRIC H-10-B ELECTRONIC LEAK

DETECTOR.

LOCATE, REPAIR, AND REPORT ANY R-22 LEAKS.

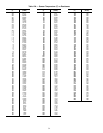

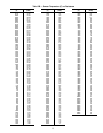

CHECK VOLTAGE IMBALANCE: AB AC BC

AB + AC + BC (divided by 3) = AVERAGE VOLTAGE = V

MAXIMUM DEVIATION FROM AVERAGE VOLTAGE =

(MAX. DEVIATION)

VOLTAGE IMBALANCE = x 100 = % VOLTAGE IMBALANCE

AVERAGE VOLTAGE

IF OVER 2% VOLTAGE IMBALANCE, DO NOT ATTEMPT TO START CHILLER!

CALL LOCAL POWER COMPANY FOR ASSISTANCE.

ASSURE THAT INCOMING POWER VOLTAGE TO CHILLER IS WITHIN RATED UNIT VOLTAGE RANGE.

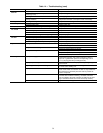

SYSTEM FLUID VOLUME IN LOOP: TYPE SYSTEM:

AIR CONDITIONING — MINIMUM 3 GAL. (3.25 L) PER NOMINAL TON (kW) =

GAL. (L)

PROCESS COOLING — MINIMUM 6 GAL. (6.5 L) PER NOMINAL TON (kW) =

GAL. (L)

CL-2