27

Model H63 Operat ing Procedures

090130

Rinsing

Step 1

Pour two gallons (7.6 liters) of cool, clean water i nto

the mix hopper . With the brushes pr ovided, scrub the

mix hopper, mix level sensing probes, the outside of

the agitator housing, and the mix inlet hole.

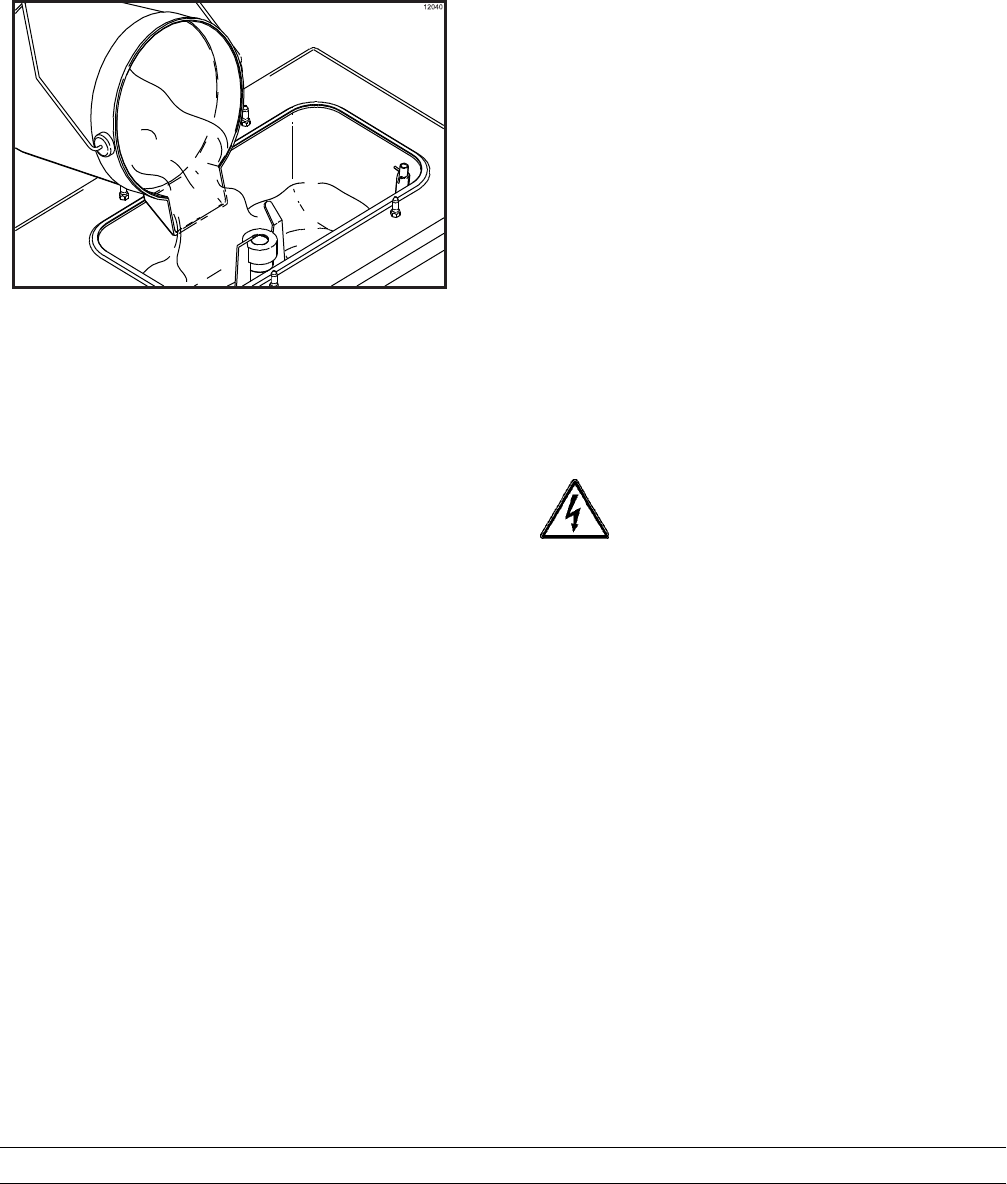

Figure 30

Step 2

With a mix pail beneath the door spout, press the

WASH key.

Step 3

Open the draw valve on the freezer door. Drain all the

rinse water from the door spout, close the draw valve,

and press the WASH key cancelling the wash cycle.

Repeat this procedure until the rinse water being

drawn from the f reezing c ylinder is clear.

Hopper Cleaning

Step 1

Prepare a pail o f an approved 100 PPM cleaning solu-

tion (examples: 2--1/2 gal. [9.5 liters] of Kay--5R or

2 gal. [7.6 liters ] of Stera--SheenR). USE WARM WA-

TER AND FO LLOW THE MANUFACTURER’S

SPECIFICATIONS.

Step 2

Pour the c leaning solution into the hopper and allow it

to flow into the freezing cylinder.

Step 3

While t he solution is flowing into the freezing cylinder ,

brush clean the mix hopper, mix level sensing probes,

the outside of t he agitator housing, and mix inlet hole.

Step 4

Press the WASH key and allow the c leaning solution

in the fr eezing cylinder to agitate for f ive minutes.

Step 5

Place an empty pail beneat h the door spout.

Step 6

Open t he draw valve on the freezer door and draw off

all the solution.

Step 7

Once the cleaner stops flowing fr om the door spout,

close the draw valve and press the WASH key

cancelling wash cycle.

Disassembly

Note: Failure to r emove par ts, brush c lean and then

air dry these parts , will result in dam age to the related

parts. These parts must be removed every 14 days or

the mac hine will lock--out and will not operate in the

AUTO mode.

BE SURE THE CONTROL SWITCH IS IN

THE OFF POSITION. Failure to do so may cause

injury from electrocution or hazardous moving parts.

Step 1

Lift out the torque arm. Disengage the draw arm f rom

the draw valv e bracket and rotate the bracket to the

right.

Step 2

Remove the handscrews , freezer door, torque roto r

assembly, beater , scraper blades, and drive shaftfr om

the freezing cylinder. Take these parts to t he s ink for

cleaning.

Hint : If the guide bearing is not connect ed to the end

of the torque rotor shaft, it is still lodged in the beater

drive shaft. To remove the guide bearing, insert the

torque arm into the side hole of the drive shaft and

push the bearing forward.

Step 3

Remove the front drip tr ay and splash shield.