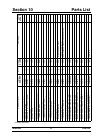

33

Model H63 Troubleshooting Guide

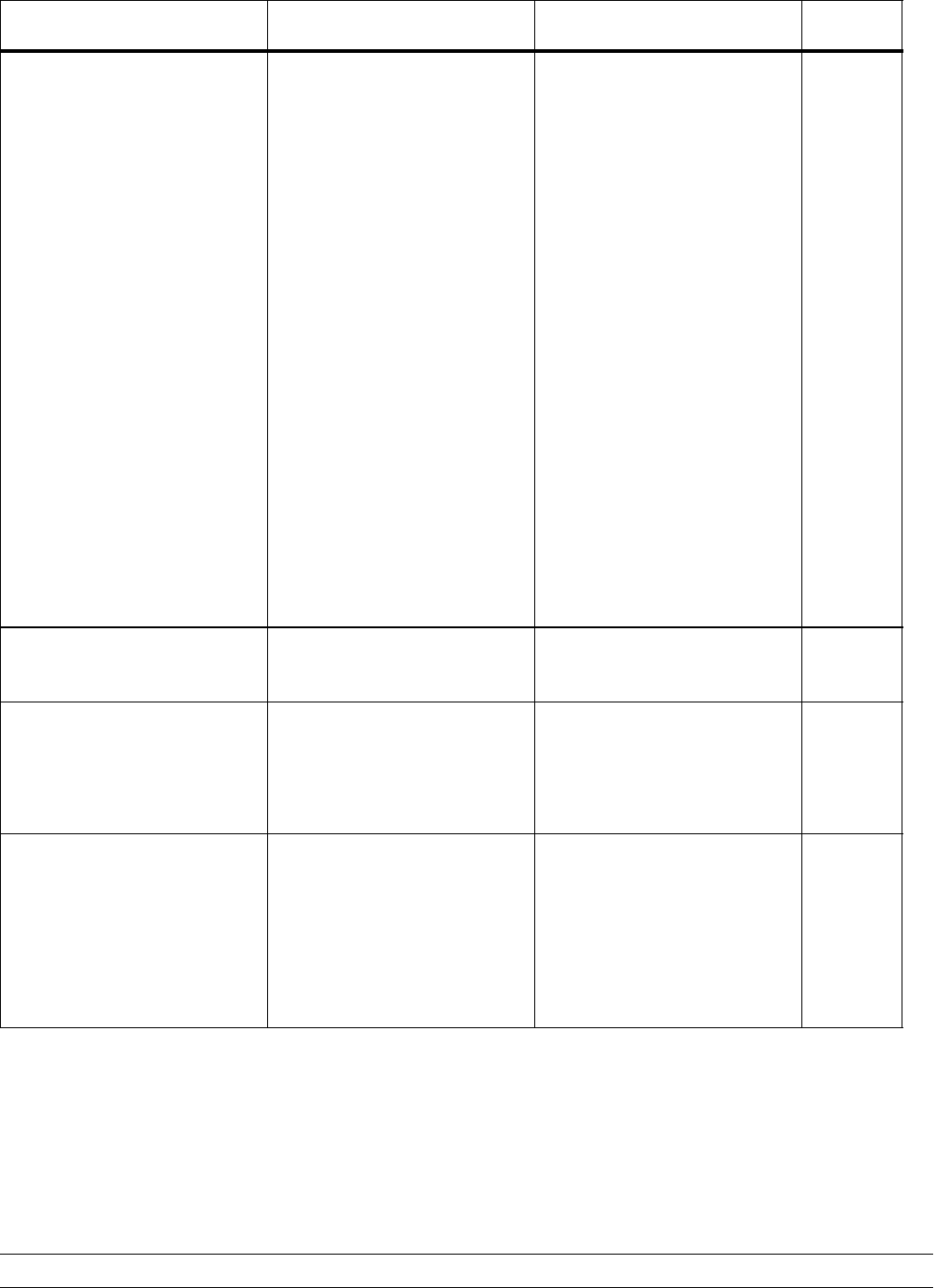

PROBLEM PROBABLE CAUSE REMEDY

PAGE

REF.

5. The p roduct is t oo soft. a. Improper consistenc y

control adjustment.

a. Pr oduct, with no syrup

blended ( vanilla), should

be dis pensed at 26_ to

28_F. (-3.3_ to -2.2_C.).

11

b. Th e tor que rotor is

binding.

b. Before installing the

torque arm, check to s ee

if the torque rotor can be

rotate d fr eely without

binding.

19

c. Improper lubrication of

torque rotor o-rings.

c. Lubricate the o- rings

properly.

20

d. Lubric ation of torque rotor

guide bear ing.

d. Do not lubricate the guide

bearing.

19

e. Not enough air space

around unit (air-cooled) .

e. Allow for adequate a ir f low

across the condenser.

2

f. The scraper blades are

worn.

f. Replace r egularly. 29

g. Dirty condenser

(air-cooled)

g. Clean regularly. 29

h. Th e mix is out-of-date. h. Use only fresh mix. 24

i. Loss of condenser

cooling.

i. Locate cause o f water

loss and correct.

-- -- --

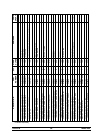

6. The mix in the hopper is

too cold.

a. Th e tem perature is out of

adjustment.

a. Call a service technician

to adjust hopper

temperature.

-- -- --

7. The mix in the hopper is

too warm while in the

AUTO mode.

a. Th e tem perature is out of

adjustment.

a. Call a service technician

to adjust hopper

temperature.

-- -- --

b. Th e hopper cover is not in

position.

b. Place the c over in

position.

24

8. The d rive s haft is stuck in

the gear box coupling.

a. Rounded corners of d rive

shaft, coupling, or both.

a. Call service technician to

correct cause and replace

the necessary

components . Do not

lubricate end of drive

shaft.

18

b. Mix and lubricant collected

in the drive coupling.

b. Br ush-clean rear shell

bearing a rea regularly.

29