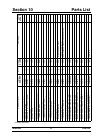

34

Model H63Troubleshooting Guide

PROBLEM PROBABLE CAUSE REMEDY

PAGE

REF.

9. The freezing cylinder walls

are scored.

a. Th e beater assembly is

bent.

a. Call a service technician

to repair or replace beater

and to correct cause of

insufficient mix in f reezing

cylinder.

-- -- --

b. Th e fr ont bearing i s

missing or worn.

b. In stall or replace front

bearing.

20

c. The gear box is out of

alignment.

c. Call a service technician

to realign gear box.

-- -- --

d. Th e beater pins are

broken.

d. Call service technician to

repair or replace.

29

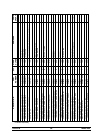

10. Excessive mix l eakage

from the dispensing s pout.

a. Th e draw valve o-rings

are w orn or missing.

a. Replace regularly. 36

b. There is unadequate

lubrication on the draw

valve o-rings.

b. Lubric ate properly. 20

c. The wrong type of

lubricant was being used

(Example: petroleum base

lubricant) .

c. Use f ood grade lubricant

(Example: Taylor Lube

High P erformance) .

18

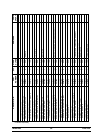

11. Excessive mix leakage

into the r ear drip pan.

a. Worn or missing s eal on

drive shaft.

a. Replace regularly. 29

b. Inadequate lubrication of

drive shaft.

b. Fo llow lubrication

procedures in “ Assembly”.

18

c. Bad rear shell bearing. c. Call serv ice technician to

replace rear s hell bearing.

-- -- --

d. Driv e shaft and beater

working forward.

d. Call service technician. -- -- --

e. Seal installed inside-out

on dr ive shaft.

e. In stall c orrectly. 18