16

Model 8756Operating Procedures

Section 6 Operating Procedures

The Model 8756 has two freezing cylinders. The size

of each freezing cylinder is 3.4 quarts (3.2 liters).

Mix is stored in the lower front refrigerated

compartment and is pumped up to the freezing

cylinder by an air/mix pump.

Duplicate the following procedures, where they

apply, for the second freezing cylinder.

We begin our instructions at the point where we

enter the store in the morning and find the parts laid

out to air dry from the previous night's brush

cleaning.

If you are disassembling the machine for the first

time, or need information to get to this starting point

in our instructions, turn to page 32, “Disassembly”

and start there.

Assembly

MAKE SURE THE POWER SWITCH IS IN

THE “OFF” POSITION. Failure to follow this

instruction may result in electrocution or injury to

fingers or hands from hazardous moving parts.

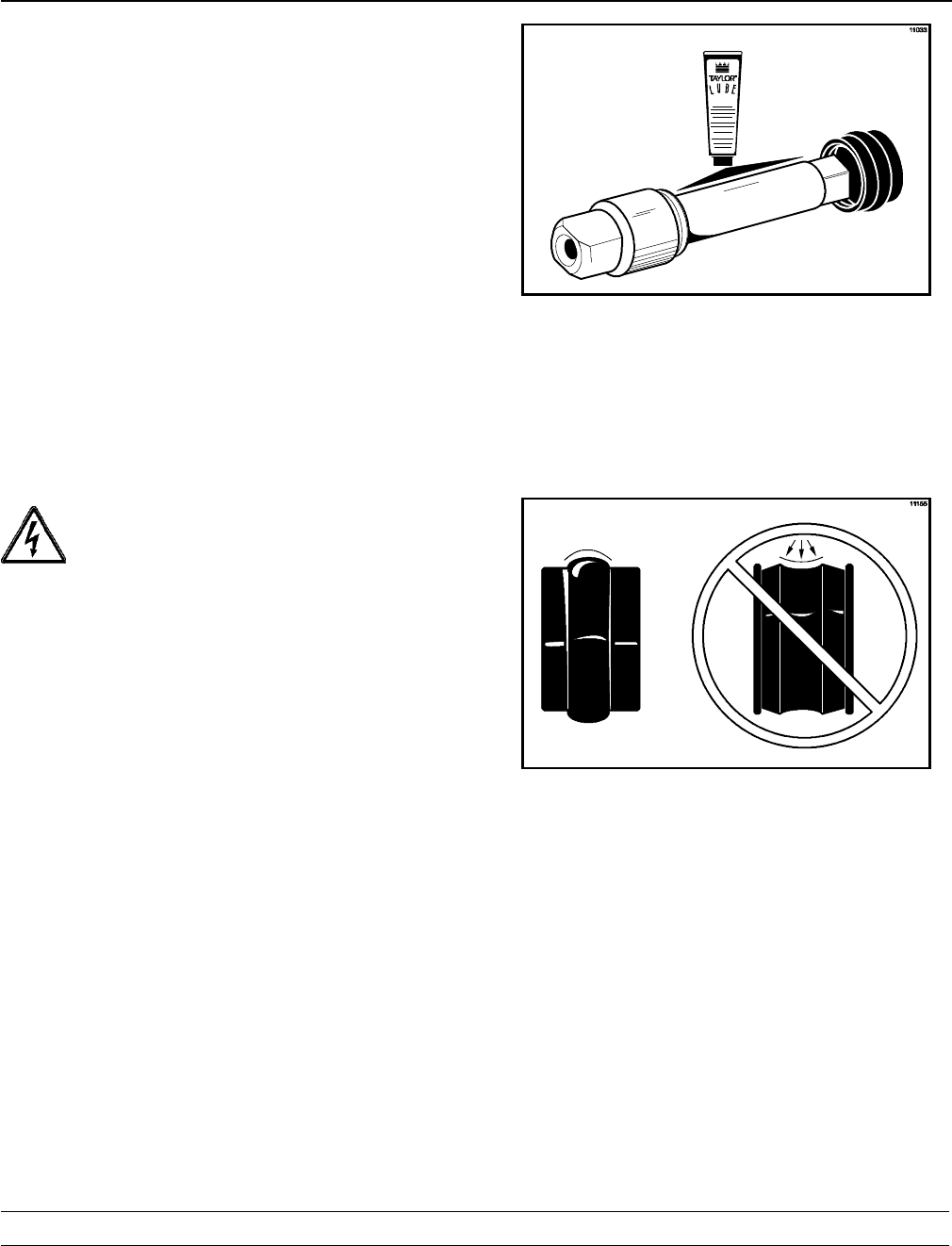

Step 1

Lubricate the groove and shaft portion that comes in

contact with the bearing on the beater drive shaft.

Slide the seal over the shaft and groove until it

snaps into place. DO NOT lubricate the hex end of

the drive shaft. Fill the inside portion of the seal

with1/4” more lubricant and evenly lubricate the end

of the seal that fits onto the rear shell bearing.

Figure 6

Note: For ease of cleaning, the seal may be turned

inside out. Be sure to position the seal correctly

during assembly.

Figure 7