9

(continued)

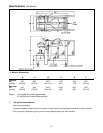

DETERMINE THE BOX LIMITATIONS BY COMPLETING THIS FORMULA:

BOX LENGTH IN DIRECTION OF SEAL MUST BE GREATER THAN .6

BOX HEIGHT

If any of the above criteria are not met boxes should be test run to assure proper machine performance.

Specifications (Continued)

9. Box Weight and Size Capacities:

A. Box Weight, filled – contents must support flaps.

Minimum – weight must be sufficient to hold carton on the conveyor bed with bottom flaps fully closed

or 1.4 kg [3 lb.] minimum.

Maximum – 40 kg [85 lb.]

B. Box Size:

Minimum: Length – 150 mm [6 inches] Maximum: Length – 760 mm [30 inches]

Width – 145 mm [5-3/4 inches] Width – 545 mm [21-1/2 inches]

Height – 120 mm [4-3/4 inches]*

Height – 620 mm [24-1/2 inches]**

* Boxes lower than 165 mm [6-1/2 inches] and wider than 320 mm [12-1/2 inches] require removal of

compression rollers.

With taping heads adjusted to apply 50 mm [2 inch] tape legs, minimum box height is 95 mm

[3-3/4 inches] with box widths greater than 195 mm[7-3/4 inches]. See "Special Set-Up Procedure -

Changing the Tape Leg Length", page 34.

** With columns adjusted to upper position, maximum box height increase to 725 mm [28-1/2 inches] and

minimum box height increases to 225 mm [8-3/4 inches]. See "Special Set-Up Procedure – Outer

Column Re-Positioning", page 35.

Note – The case sealer is designed to accommodate most boxes complying with the 1976 FBA and

PMMI*** voluntary standard "Tolerances for Top Opening" regular slotted containers (RSC).

Two of the requirements of the standard are the following:

1. The box length is not more than twice the box width.

2. The box length is not more than four times the box depth.

In addition, the box score lines must be sufficient to facilitate automatic flap folding. Certain

environmental conditions, such as high humidity, can be detrimental to automatic flap folding.

***Fibre Box Association, Packaging Machinery Manufacturer's Association