13

Installation and Set-Up (Continued)

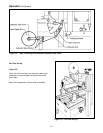

8. Install case sealer in production line. When installing the case sealer, be sure to observe the following

guidelines.

a. Case sealer must be installed level – it is not designed to convey boxes uphill.

b. Infeed conveyor must convey boxes to case sealer at a speed not to exceed 0.30 m/s [60 f/m].

c. Precautions must be taken to prevent excessive box pressure against the case sealer infeed gate.

This will help to prevent damage to the boxes and ensure proper performance.

d. Infeed and exit conveyors must provide straight entrance and exit of boxes to/from case sealer and exit

conveyor must positively convey boxes away from machine.

e. Refer to Figure 2-3 for suggested conveyor types that can be used with the case sealer.

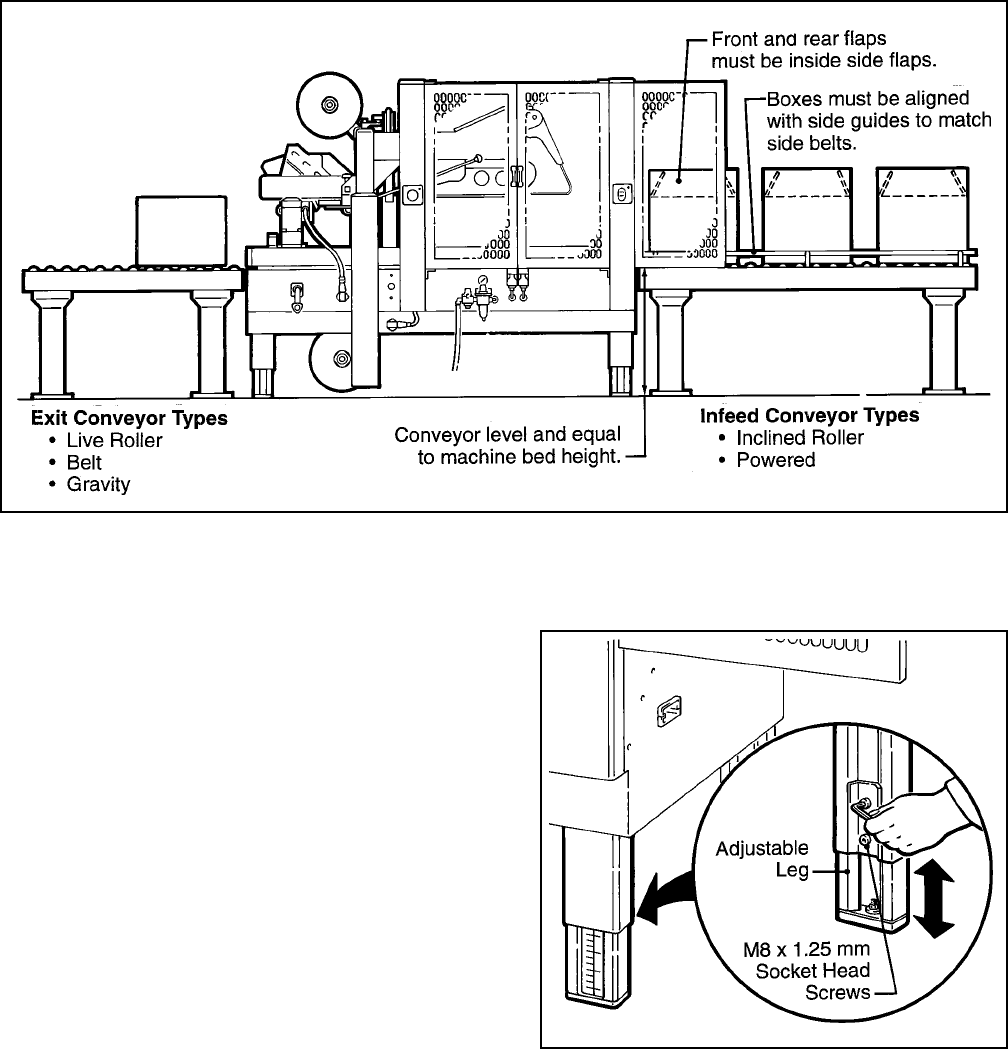

9. Adjust case sealer bed height. The adjustable

legs provide different machine bed heights from

610 mm [24 inches] minimum to 890 mm

[35 inches] maximum.

Refer to Figure 2-4 and set the machine bed

height as follows:

a. Block up the machine frame to allow

adequate leg adjustment.

b. Loosen, but do not remove, two M8 x 1.25

mm socket head screws in one leg (use M6

hex key wrench). Adjust the leg length for

the desired machine bed height. Retighten

the two screws to secure the leg. Adjust all

four legs equally.

10. Tape width – the taping heads have been pre-

set to accommodate 72 mm [3 inch] wide tape

rolls. To apply narrower width tapes, refer to

Section II, "Adjustments – Tape Web

Alignment", page 11.

Figure 2-4 – Conveyor Bed Height Adjustment

Figure 2-3 – Conveyor Systems