25

Maintenance

The case sealer been designed for long, trouble

free service. The machine will perform best when it

receives routine maintenance and cleaning.

Machine components that fail or wear excessively

should be promptly repaired or replaced to prevent

damage to other portions of the machine or to the

product.

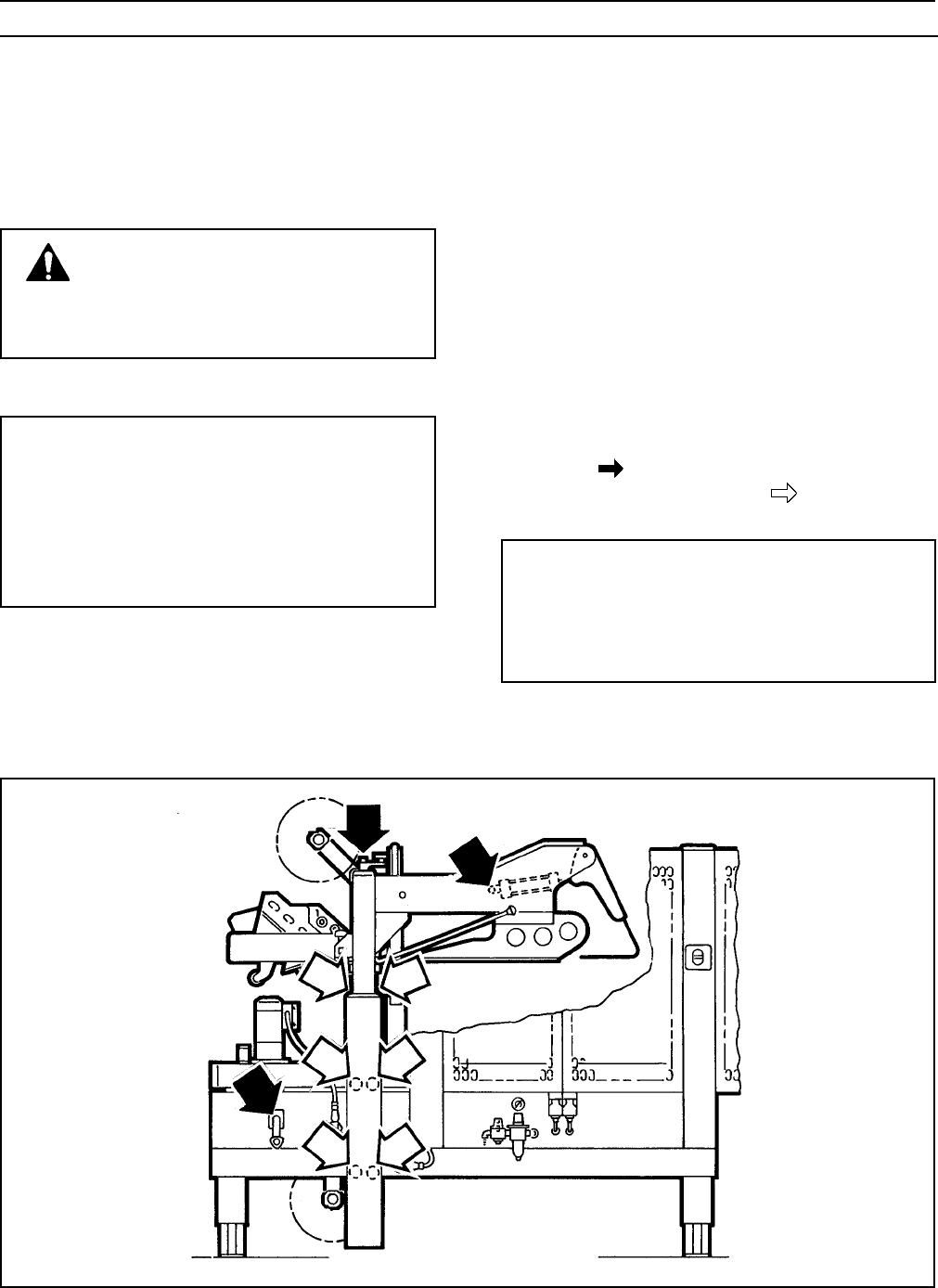

Figure 4-1 – Lubrication Points, Frame

WARNING – Turn air and electrical

supplies off and disconnect before

beginning maintenance. Failure to comply

with this warning could result in severe

personal injury or equipment damage.

Cleaning

Note – Never attempt to remove dirt by blowing

it out with compressed air. This can cause the

dirt to be blown inside the motor and onto

sliding surfaces which may cause premature

equipment wear. Never wash down or subject

equipment to conditions causing moisture

condensation on components. Serious

equipment damage could result.

Regular slotted containers produce a great deal of

dust and paper chips when processed or handled in

equipment. If this dust is allowed to build-up on

machine components, it can cause component

wear and overheating of drive motor. The dust

build-up can best be removed from the machine by

Note – Wipe off excess oil and grease. It will

attract dust and dirt which can cause premature

equipment wear and jamming. Take care that

oil and grease are not left on the surface of

rollers around which tape is threaded, as it can

contaminate the tape's adhesive.

a shop vacuum. Depending on the number and

type of boxes sealed in the case sealer, this

cleaning should be done approximately once per

month. If the boxes sealed are dirty, or if the

environment in which the machine operates is

dusty, cleaning on a more frequent basis may be

necessary. Excessive dirt build-up that cannot be

removed by vacuuming should be wiped off with a

damp cloth.

Lubrication

Most of the machine bearings, including the drive

motor, are permanently lubricated and sealed and

do not require additional lubricant.

Figure 4-1 illustrates the areas of the case sealer

that require lubrication. Lubricate points indicated

by arrows ( ) with SAE #30 non-detergent oil

and points indicated by arrows ( ) with a small

amount of multi-purpose grease.

TAPING HEAD LUBRICATION – See Section II,

""Maintenance – Lubrication", page 10.