MODEL C24EA - SWITCHES, SOLENOIDS, RELAY, AND BUZZER

F35453 (July 2008) Page 28 of 68

Check

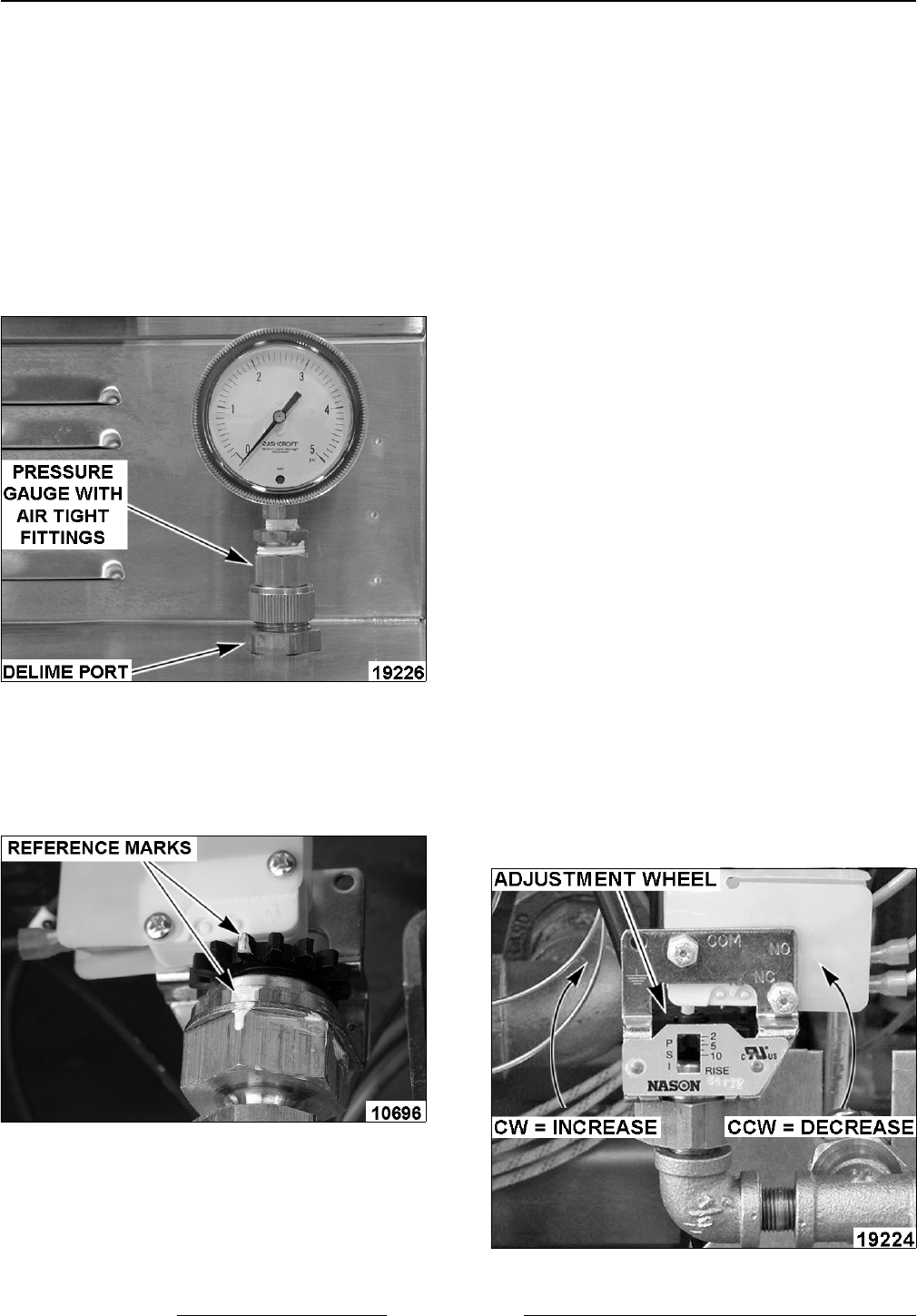

NOTE: Pressure can be checked with the small air

pocket that exists between the delime port cap and

water level probe housing in the delime hose. Make

certain that no leaks exist in the steam generator

connections or pressure gauge fittings.

1. Turn off machine to drain steam generator.

Allow steamer to complete drain cycle.

2. Remove FRONT BASE PANEL as outlined

under COVERS AND PANELS.

3. Remove cap from delime port and install

pressure gauge.

4. Close cooking compartment doors.

5. Mark one tooth of pressure switch adjustment

wheel to aid in identifying position of wheel.

Make a second mark on body of pressure

switch in alignment with mark on adjustment

wheel.

6. Turn on machine and allow to pressurize (ready

light on).

A. Set one cook timer for approximately 15

minutes.

B. Allow steamer to cycle three times for

steam production to stabilize.

NOTE: Operating pressures will vary slightly

between machine being serviced and gauge

used.

7. While observing pressure gauge, listen for

contactor to release indicating that pressure

switch contacts have opened. Correct range for

pressure switch cut-out is between 3.5 to 3.7

psi.

A. Listen for switch contacts to close

(contactor will energize).

B. Observe pressure gauge for three

complete cycles to find the average cut-out

pressure. Record pressure.

C. If pressure is outside tolerance (3.5 to 3.7

psi), adjustment is necessary. Refer to

Adjustment.

D. If cut-out pressure is within specifications,

turn power switch off. Allow time for

steamer to drain.

8. Remove test gauge and reinstall delime cap.

Adjustment

1. Allow steam production to stabilize as outlined

under Check.

NOTE: Make small incremental adjustments (1/8

turn of toothed adjustment wheel) when adjusting

cut-out pressure.

2. Referring to cut-out pressure recorded in Check

procedure, turn adjustment wheel to bring cut-

out pressure into tolerance.

A. From looking down on pressure switch:

1) Turn adjustment wheel CCW to

decrease cut-out pressure.

2) Turn adjustment wheel CW to

increase cut-out pressure.