MODEL C24EA - CONTROL BOARD

F35453 (July 2008)Page 33 of 68

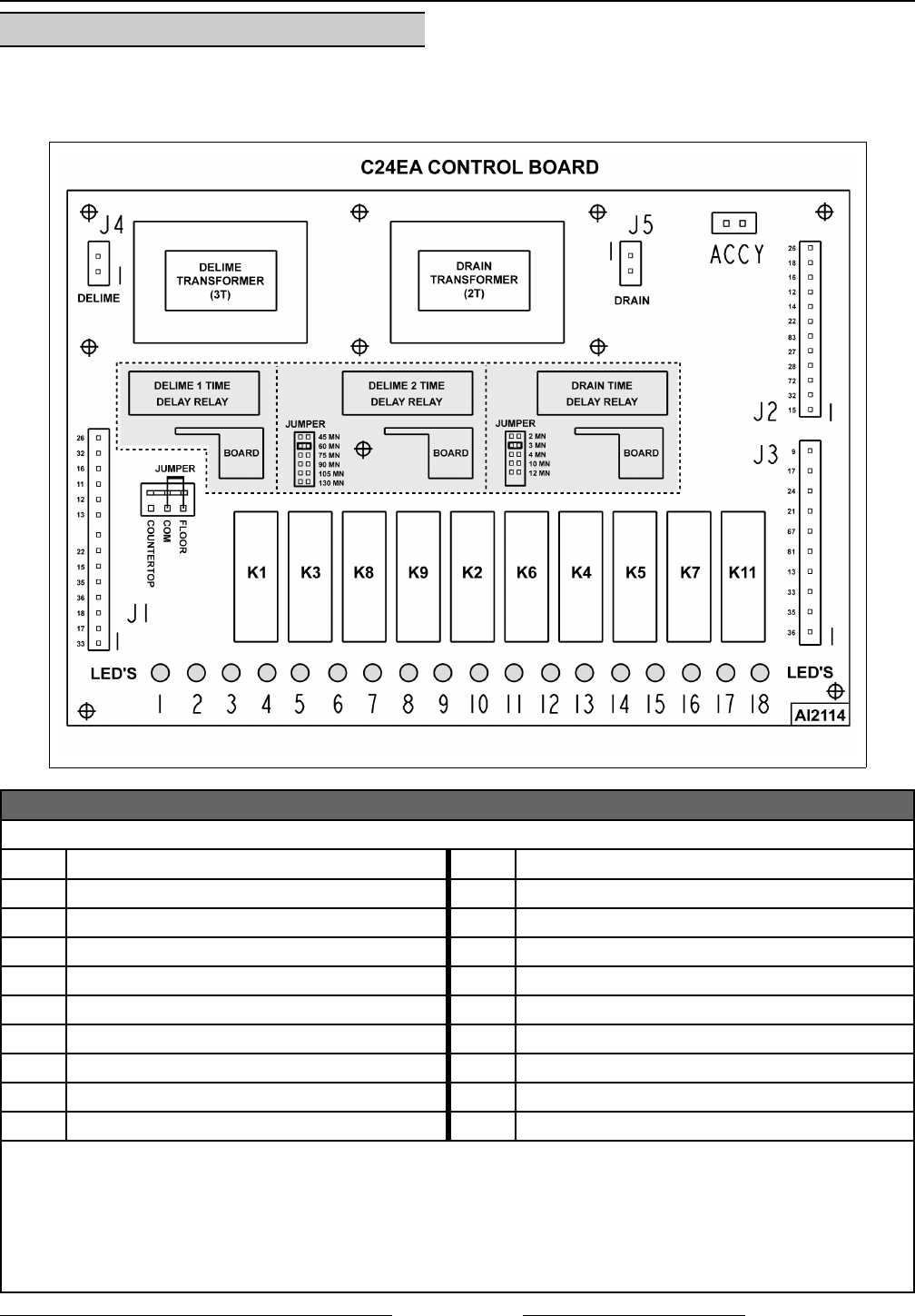

LAYOUT AND LED LEGEND

The control board provides a central location for wire harness connections and power transfer through board

relays (K1-K9, and K11) and time delay relays (delime 1, delime 2 and drain) to the steamer controls. Also,

provides a condition or component troubleshooting indicator by utilizing eighteen LED’S on the board.

LED LEGEND

LED ON = Condition satisfied or component energized. LED OFF = Condition not satisfied or component de-energized.

LED Component LED Component

1 Board powered (120VAC). 10 Drain relay (K3).

2 Limiting contactor (1CON). 11 Drain relay (K5).

3 Regulating contactor 1 (2CON).

1

12 Vacuum relief solenoid (2SOL).

4

4 Regulating contactor 2 (3CON).

2

13 Delime 1 time delay relay powered.

5 Relay (K1) energized. 14 Delime relay (K4).

6 Upper cavity relay (K8).

3

15 Delime relay (K2).

7 Lower cavity relay (K9).

3

16 Delime relay (K6).

8 Heat exchanger relay (K10). 17 Delime relay (K7).

9 Drain time delay relay (TDR). 18 High limit relay (K11).

1. Contactor will cycle heating elements to maintain steam generator pressure when one or both compartments are in use;

or when idling to maintain pressure when compartments are not in use.

2. Contactor will cycle heating elements as necessary to maintain steam generator pressure when both compartments are

in use.

3. K8 and K9 must be energized for heat exchanger relay (K12) to be energized. Heat exchanger element (2) is then

powered.

4. Allows venting of steam generator.