FORM 160.55-O1 (604)

127

YORK INTERNATIONAL

CHECKING OP ER A TION

During operation, the fol low ing con di tions should be

periodically checked:

1. On start ing, the prerotation vanes should re main

closed.

2. Be sure the oil pump is operating while unit is run-

ning.

3. Check Oil Pressure display. A gradual de crease in

bearing oil pres sure of 5 to 10 PSI (with con stant

suc tion and discharge pres sures) may be an in di -

ca tion of a dirty Þ lter. The Þ lter should be replaced

when pres sure loss is 30% or more of the orig i nal

pres sure. The actual bearing oil pressure will vary

with com pres sor suction and discharge pres sures.

When a new sys tem is Þ rst operated under nor mal

full load conditions, the bearing oil pressure should

be re cord ed as a ref er ence point with which to com-

pare sub se quent read ings.

OPERATING LOG SHEET

A per ma nent daily record of system operating con di -

tions (tem per a tures and pres sures) recorded at regular

intervals throughout each 24 hour operating period

should be kept.

LD00466

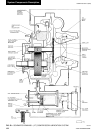

FIG. 56 – MINIMUM ENTERING CONDENSING

WATER TEMPERATURE

FIG. 57 – LIQUID CHILLER LOG SHEETS

*NOTE: These items can be printed by an electronic printer connected to the Microboard

and pressing the PRINT key on the Keypad or automatically using the Data Logger feature.

LD00467

23889A

4