YORK INTERNATIONAL

94

FORM 160.55-O1 (604)

DISPLAY MESSAGES

The Status Bar of the Display contains a Status Line

and, beneath it a Details Line. The Status Line con tains

a message describing the operating state of the chiller;

whether it is stopped, running, starting or shutting down.

The Details Line displays Warning, Cycling, Safety,

Start Inhibit and other messages that provide further

details of the Status Bar messages. The Status Mes sag es

list ed be low are displayed on the Status Line. All other

mes sag es are displayed on the Details Line.

To aid in the meaning of the message, messages are

displayed in different colors as follows:

Normal Operation mes sag es - Green

Warning messages - Yellow

Cycling Shutdown mes sag es - Orange

Safety Shutdown mes sag es - Red

STATUS MESSAGES

“SYSTEM READY TO START”

The chiller is shut down but will start upon receipt of a

Local or Remote start signal.

“CYCLING SHUTDOWN – AUTO RESTART”

The chiller is shut down on a CYCLING shutdown. The

cause of the shutdown is still in effect and is dis played

on the Details line of the Status Bar. The chiller will

au to mat i cal ly restart when the CYCLING con di tion

clears.

“SAFETY SHUTDOWN – MANUAL RESTART”

The chiller is shut down on a SAFETY shutdown. The

cause of the shutdown is still in effect and is displayed

on the Details line of the Status Bar. The chiller can be

started after the Safety condition clears and the Op er a tor

moves the COMPRESSOR switch to the STOP-RESET

(O) position.

“SYSTEM PRELUBE”

A chiller start has been initiated and the pre-start lu-

bri ca tion is being performed. The Prelube duration is

ei ther 30 seconds or 180 seconds, as conÞ gured with

a Microboard Program Switch. The Pre-lube duration

must nev er be changed by anyone other than a quali-

Þ ed Ser vice Tech ni cian. The standard Prelube duration

is 30 sec onds.

“SYSTEM RUN”

The chiller is running under the condition described in

the Details Line of the Status Bar.

“SYSTEM COASTDOWN”

The chiller has shut down and the Post-run lubrication is

being performed. On electric motor drive ap pli ca tions,

the Postlube duration is 150 seconds. On Steam Tur bine

applications, it is 15 minutes. The actual du ra tion is de-

ter mined by a Microboard Program Jumper, con Þ g ured

by a qualiÞ ed Service technician.

“START INHIBIT”

The chiller is prevented from being started due to the

reason displayed on the Details Line of the Status bar.

RUN MESSAGES

“MOTOR – HIGH CURRENT LIM IT”

The Compressor Motor current is > the Local or Re mote

Current Limit Setpoint. The Current Limit Setpoint is

pro grammed over a range of 30 to 100% of the Chill er

Full Load Amps (FLA). When the motor current in-

creas es to the “inhibit open” threshold, the Pre-rotation

Vanes are inhibited from further opening. This prevents

a fur ther cur rent rise. If the current continues to rise

to the “start close” threshold, the Vanes begin closing

until the current falls to the “stop close” threshold. Au-

to mat ic Vane operation is resumed and this message

au to mat i cal ly clears when the motor current decreases to

the “allow open” thresh old. The thresholds are dif fer ent

for the var i ous motor start er applications. To allow Þ eld

calibration of the Solid State Starter (Mod “A”) Logic

Board or CM-2 Current Module, pressing the Slide Valve

Load key in Service access level, starts a 10 minute timer

during which the current limit thresh olds are elevated.

Refer to table on next page.

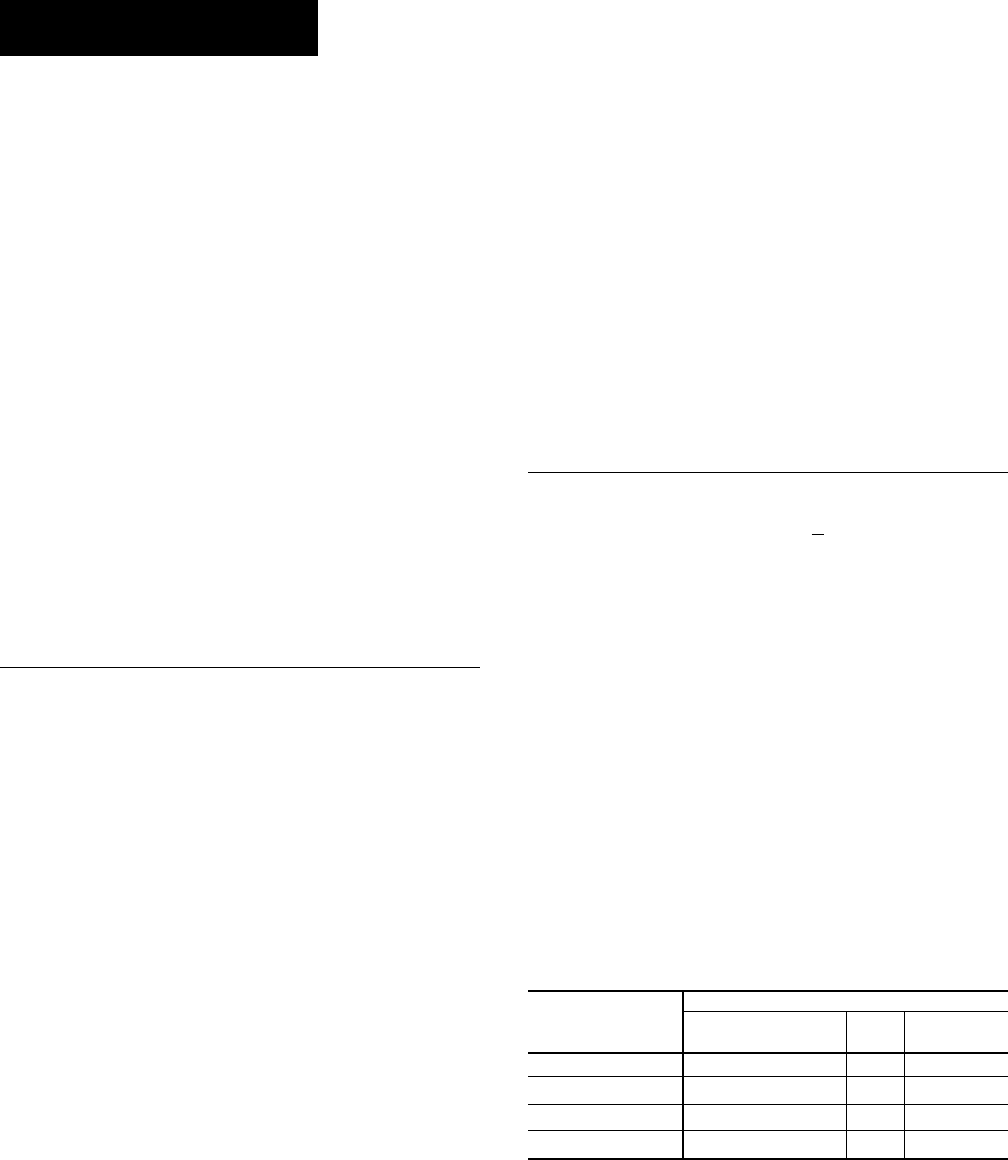

Vane Control

Motor Current (%FLA)

Electro-Me chan i cal/

VSD Ser vice Mode

Solid state starter

On rise, inhibit open 100 100 107

On fall, allow open 98 98 106

On rise, start close 104 103 110

On fall, stop close 102 101 109

An example of current limit is as follows: If a Solid Sate

Starter chiller FLA is 100 Amps and the Current Limit

Setpoint is 50%, the following will occur:

50 Amps – inhibit vane open

52 Amps – vanes begin closing

51 Amps – vanes stop closing

49 Amps – allow automatic vane control

“LEAVING CHILLED LIQUID CONTROL”

The chiller is running, controlling the Leaving Chilled

Liq uid to the Leaving Chilled Liquid Temperature

Setpoint. There are no system conditions inhibiting

this operation.

OptiView Control Center