-31-

Revision 4/F3576 © Moffat Ltd, December 2004

Injection

Nozzle

Units Manufactured up to S/N 275353

1) Remove right hand side panel (refer

6.2.4).

2) Disconnect the two wires leading to the

gas solenoid.

3) Disconnect main gas supply pipe from

copper connection line to manifold.

4) Loosen pipe clamp at rear of oven and

remove main supply pipe assy.

5) On work bench undo gas solenoid valve

from assembly and replace.

Figure 6.3.25

Solenoid Valve

1) Ensure water supply is turned off.

2) Remove the water injection nozzle from

inside the oven (refer 6.3.19).

3) Remove the water solenoid access panel

at the rear of the oven (4 screws).

6.3.20 WATER SOLENOID VALVE

1) Remove the fan baffle (refer 6.2.2).

2) Unscrew the water injection nozzle.

3) Clean or replace nozzle, and reassemble

in reverse order.

6.3.19 WATER INJECTION NOZZLE

Figure 6.3.26

Figure 6.3.27

4) Remove the wires from the solenoid, and

disconnect the mains water connection.

5) Remove the two screws securing the

solenoid bracket to the oven rear, and

remove the valve assembly.

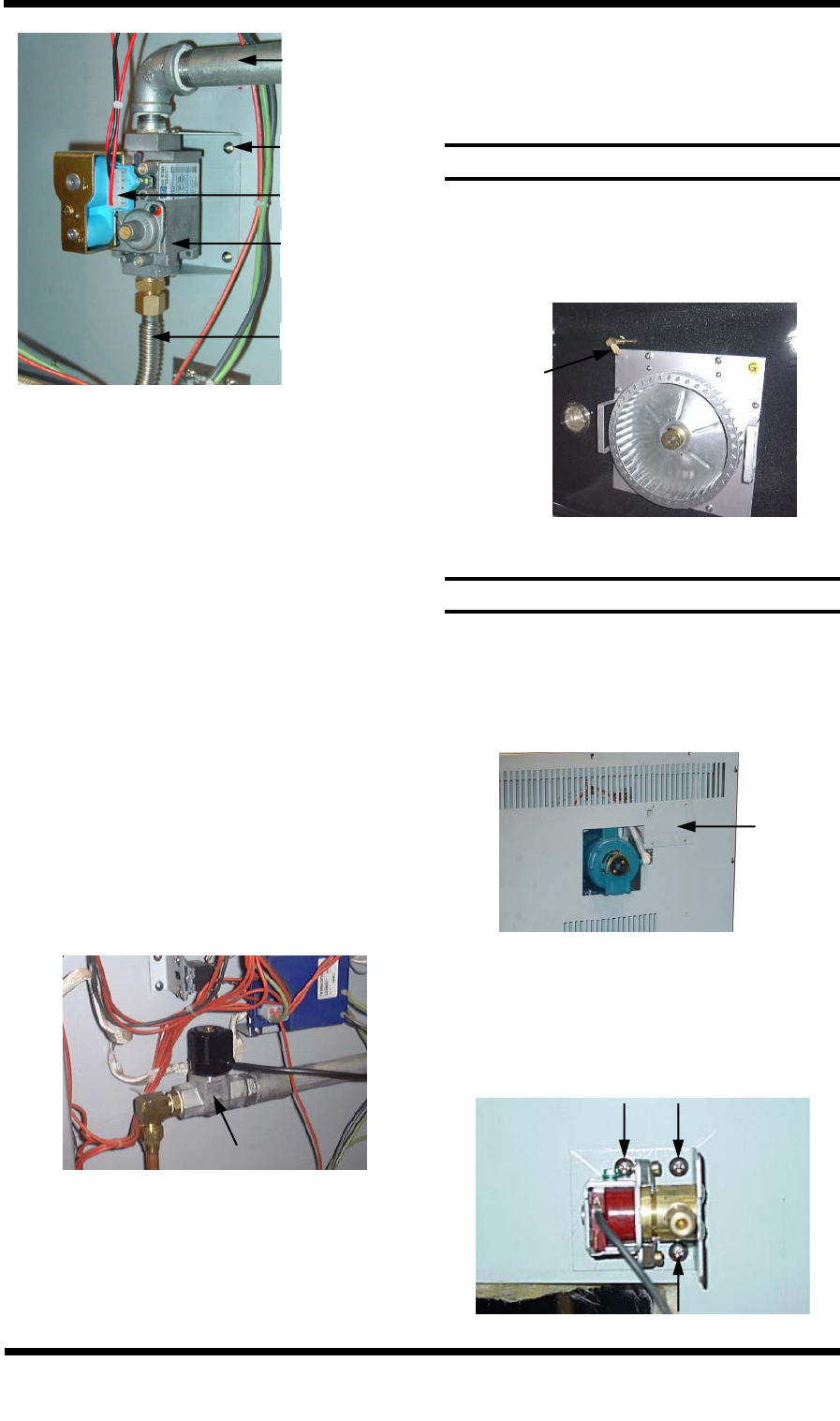

Figure 6.3.28

Water

solenoid

access panel

4) Disconnect gas supply at rear of oven,

remove saddle clamp holding the gas inlet

pipe (two screws).

5) Remove the four screws securing valve

bracket to oven, remove valve and inlet

pipe from the oven.

6) Unscrew gas inlet pipe and elbow from

the valve. Remove the four screws (two

top and bottom) securing the valve to the

bracket, remove valve.

7) Fit new valve to the bracket and

re-assemble in reverse order.

8) Leak test all new connections.

Figure 6.3.24

Gas Inlet Pipe

Wiring Plug

Flex-tube

Gas Valve

(four screws)

Valve Bracket

(four screws)

6) Refit and reconnect solenoid wires using

reverse procedure.

7) Leak test all new connections.