7

312028000

INSTALLATION

This section covers unpacking and inspection, installing Loose-Shipped Parts, selecting location, installing Unit,

preparing for operation, and operation.

UNPACKING AND INSPECTION

(see Figure 5)

NOTE: The Unit was thoroughly inspected before leaving the factory and the carrier has accepted and

signed for it. Any damage or irregularities should be noted at time of delivery (or not later than 15 days

from date of delivery) and immediately reported to the delivering carrier. Request a written inspection

report from a Claims Inspector to substantiate any necessary claim. File claim with the delivering carri-

er, not with IMI Cornelius Inc.

1. After Unit has been unpacked, remove shipping tape and other packing material.

2. Remove Unit sides and back panels as instructed.

3. Remove shipping bolts that secure Unit to skid, then remove skid.

4. Unpack Loose-Shipped Parts. Make sure all items are present and in good condition.

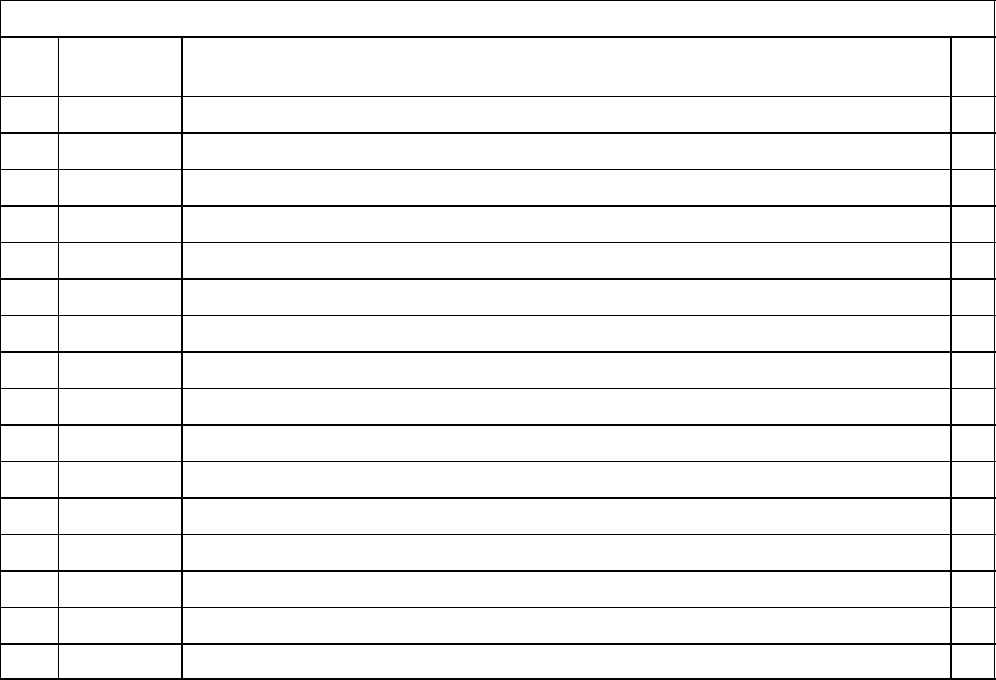

Table 3. Loose-Shipped Parts

Item

No. Part No. Name Qty.

1 178025100 Tapered Gasket, White 4

2 322859000 Spanner Wrench, Dispensing Valve 1

3 325216000 Cleaning Brush 1

4 311304000 Tapered Gasket, Black 1

5 317660000 Cup Rest 1

6 325282000 Thread Cutting Screw, Hex Hd.; No. 8 by 18 by 1/2-in. long 2

7 2738 Drip Tray Support, Left 1

8 2739 Drip Tray Support, Right 1

9 317659029 Drip Tray 1

10 326002000 Kit, Drip Tray Drain Hose 1

11 2899 Wrench, Rear Seal Housing 1

12 3810 Tool, Drive/Coupler Adjustment Gauge 1

13 324252000 Leveling Leg 4

14 3247 Spacer, White 2

15 3221 Front Access Panel 1

16 3108 Thread Cutting Screw, Phil Pan Hd; No. 10 by 32 by 1-in. long 2

IDENTIFICATION OF LOOSE-SHIPPED PARTS

1. Tapered gaskets, white (item 1) are used to seal connections when connecting Unit product inlet lines to

product tanks and connecting Unit CO

2

inlet line to CO

2

source.

2. Spanner wrench, dispensing valve (item 2) is used to remove shank nuts securing dispensing valves to

faceplates.