13 312028000

STARTING FCB AND ADJUSTING WATER-TO-SYRUP “RATIO” (BRIX) OF DISPENSED

PRODUCT

1. Open shutoff valve in city plain water line connected to the Unit. Check for water leaks and tighten or repair

leaks if evident. ‘‘H

2

O OUT’’ fault message should have gone out but ‘‘SYRUP 1’’, and ‘‘SYRUP 2’’ fault mes-

sages will continue to be displayed.

IMPORTANT: Product shutoff valves, located in lines leading from product blender tanks to freeze

cylinders (see Figure 2 and 6), must be closed at this time. Closing valves prevents product from filling

freeze cylinders while checking BRIX of product in product blender tanks.

2. Close product shutoff valves, located in lines leading from product blender tanks to freeze cylinders, to pre-

vent product from entering cylinders.

IMPORTANT: The following CO

2

and liquid disconnects disconnecting and connecting procedure for

soft drink tank replacement or filling soft drink tank in place must be performed in order as follows:

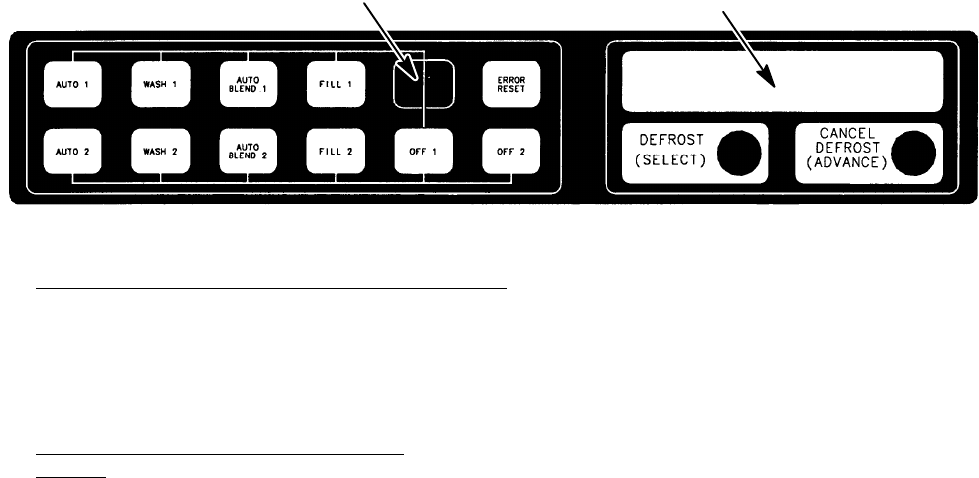

HIDDEN SECURITY

SWITCH

MESSAGE DISPLAY

FIGURE 3. CONTROL PANEL ASS’Y

To disconnect soft drink tank from Unit syrup system.

A. Disconnect liquid disconnect from soft drink tank. NOTE – Disconnecting liquid quick disconnect

from soft drink tank first prevents syrup from backflowing through Unit syrup flow regulator

which may alter regulator adjustment.

B. Second, disconnect CO

2

quick disconnect from soft drink tank.

To connect soft drink tank into Unit syrup

system.

A. First, connect CO

2

quick disconnect to soft drink tank to pressurize the tank.

B. Second, connect liquid quick disconnect to the soft drink tank.

3. Pressurize soft drink tanks containing syrup, then connect tanks into Unit syrup systems.“OFF 1”, “OFF 2”,

“SYRUP 1”, and “SYRUP 2” fault messages will continue to be displayed.

4. The following steps A through J are instructions for adjusting the Water-to-Syrup “Ratio” (BRIX)

of the dispensed product on one of the systems.

NOTE: The Unit control panel assembly is equipped with a hidden “SECURITY SWITCH” located be-

tween “FILL 1” and “ERROR RESET” control switches (see Figure 3). Pressing in and holding the

“SECURITY SWITCH” for 3 seconds deactivates the control switches preventing tampering with Unit

normal operation. To reactivate the control switches, press in and hold the “SECURITY SWITCH” for 3

seconds.

NOTE: The adjustable carbonated water flow regulators (see Figure 2 and 12) located in their respective

systems, control carbonated water flow rate to the product blender tanks. The water flow regulators are

factory adjusted at 1.3 0.05 oz/second and should not normally require adjustment. If adjustment is

necessary, adjust as instructed.

A. Press ‘‘FILL 1’’ switch to fill No. 1 syrup system sold-out float. ‘‘SYRUP 1’’ fault message will go out and

‘‘FILL 1’’ fault message will come on. ‘‘OFF 1’’, ‘‘OFF 2’’, and ‘‘SYRUP 2’’ fault messages will continue to

be displayed.