1-5

SECTION 1

DESCRIPTION

II. COMPONENT FUNCTION

The components for the lower and upper ovens are identical.

The following description covers the lower oven.

A. Conveyor

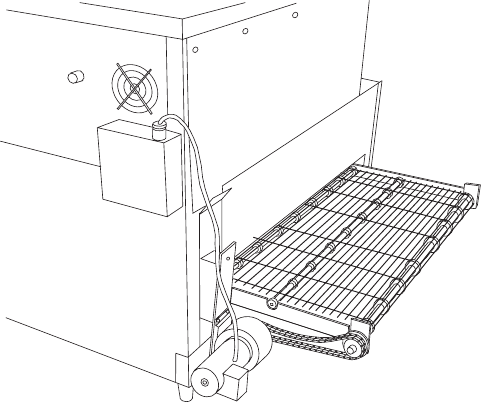

The conveyor is driven by a direct current electric motor

operating through a gear reducer, (See Figure 1-6). The motor

speed is controlled by a digital control. The stainless steel

wire belt can travel in either direction and at variable speeds.

Note that only one oven section will control the speed of the

conveyor (2 for a double tandem oven).

B. Gas Burner

Turning the heat switch to "I" will initially set up the oven purge

circuit. After approximately 45 seconds, the solid-state ignition

control lights a pilot by an electric spark.

After the pilot is lit, the main valve will open, permitting gas to go

to the burner and heat the oven.

The main burner and pilot gas are extinguished when heat is off.

This system permits the main gas valve to open only when the

pilot burner is proven to be lit.

If the pilot flame does not light or a loss of flame occurs, the main

valve closes and the red lamp is lit on the "RESET" switch. The

"RESET" switch must be pushed to restart the ignition

sequence.

Note that the gas burner of each oven section is independently

controlled by that section's temperature controller.

C. Front Window

A front window provides access to each section of the oven for

items which do not require full bake time, such as sandwiches,

cookies, small items or cheese melting processes.

The window is also used for viewing items being baked and

for cleaning.

Figure 1-6. Conveyor Drive Motor