34

Model C300Troubleshooting Guide

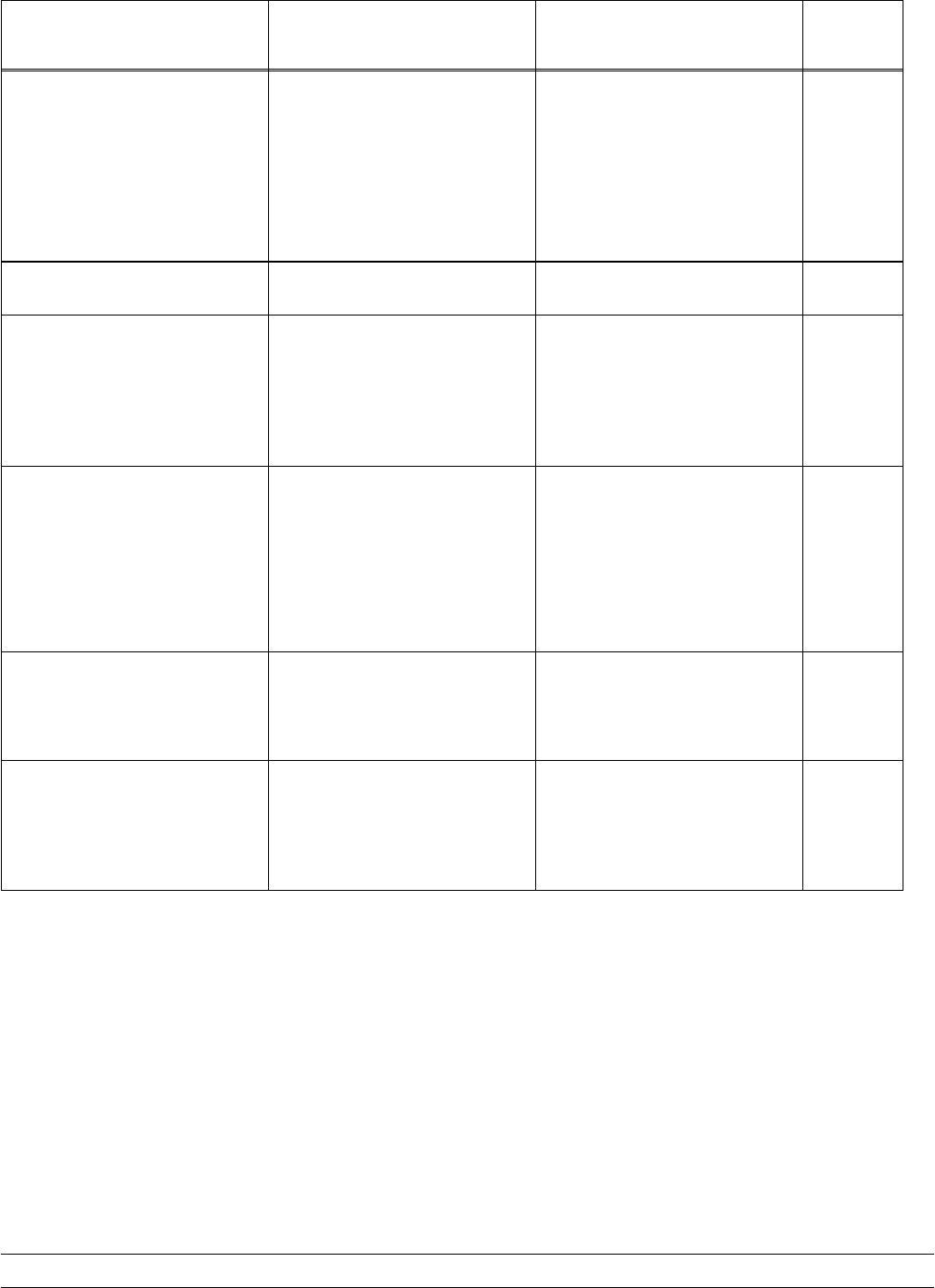

PROBLEM PROBABLE CAUSE REMEDY PAGE

REF.

6. Unable to remove the

drive shaft from the rear

shell bearing.

a. Rounded corners o f hex

end of drive shaft, drive

coupling, or both.

a. Replace the drive shaft, or

call a service technician to

replace the direct dr ive

unit.

---

b. Lubrication o f hex end of

drive shaft.

b. Do not lubricate the hex

end. If nec essary, c ontact

a service technician for

removal.

18

7. Excessive loss of CO

2

. a. Leak in the C O

2

system. a. Contact a service

technician.

---

8. Leakage from rear drip

pan(s) into front drip tray.

a. Seal or o- ring on drive

shaft is w orn, m issing, or

incorrectly installed.

a. Replace or install c orrectly

on drive shaft.

18

b. Worn rear shell bearing. b. Contact a service

technician to replace rear

shell bearing.

---

9. Excessive mix leakage

from door spout.

a. Inadequate l ubrication o f

draw valve o- rings.

a. Lubricate p roperly.

20

b. Wrong type lubr icant on

draw valve o- rings.

b. Use food grade lubricant

(example: Taylor Lube

HP).

18

c. Worn or missing dr aw

valve o- rings.

c. Replace or install o- rings

on draw valve.

20/ 35

10. Unable to adjust brix. a. Syrup lines need to be

cleaned and sanitized.

a. Clean and sanitize syrup

lines.

---

b. Blocked flow control. b. Contact a service

technician.

---

11 . Lack of syrup being

supplied to machine.

a. Loss of CO

2

to propel

syrup.

a. Contact a service

technician.

---

b. Clogged or kinked syrup

lines.

b. Sanitize syrup lines

regularly. If k inked, r epair

or replace.

---