Installation

8

Ventilation

Blodgett gas deck ovens are direct fired. Heat and

flue products from the burners are introduced di-

rectly into the baking compartment. As a result,

improper venting can have a detrimental effect on

the baking characteristics of the oven. A properly

designed ventilation system will allow the oven to

function properly, while removing unwanted va-

pors and products of combustion from the oper-

ating area.

This oven may be vented using either:

D

A mechanically driven, canopy type, exhaust

hood, or

D

A direct flue arrangement.

U.S. and Canadian installations

Refer to your local ventilation codes. In the ab-

sence of local codes, refer to the National ventila-

tion code titled, “Standard for the Installation of

Equipment for the Removal of Smoke and Grease

Laden Vapors from Commercial Cooking Equip-

ment”,NFPA-96-LatestEdition.

General export installations

Installation must conform with Local and National

installation standards. Local installation codes

and/or requirements may vary. If you have any

questions regarding the proper installation and/or

operation of your Blodgett oven, please contact

your local distributor. If you do not have a local dis-

tributor, please callthe Blodgett Oven Company at

0011-802-860-3700.

THE BLODGETT OVEN COMPANY CANNOT AS-

SUME RESPONSIBILITY FOR LOSS OR DAMAGE

SUFFERED AS A RESULT OF IMPROPER INSTAL-

LA TION.

WARNING:

Failure to properly vent the oven can be

hazardous to the health of the operator

and may result in operational problems,

unsatisfactory baking and possible dam -

age to the equipment.

Damage sustained as a d irect resul t of im-

proper ventilation w ill not b e covered by

the Manufacturer’s warranty.

CANOPY TYPE EXHAUST HOOD

A mechanically driven, canopy type exhaust hood

is the preferred method of ventilation.

The hood should be sized to completely cover the

equipment plus an overhang of at least 6” (15 cm)

on all sides not adjacent to a wall. The distance

from the floor to the lower edge of the hood should

not exceed 7’ (2.1m).

The c apacity of the hood should be sized appro-

priately w ith provisions for an adequate supply of

make up air. Capacity is generally expressed in

ft

3

/min (CFM). 1 CFM of natural gas burned w ith

just enough air for complete combustion pro-

duces 11 CFM of combustion products. In virtually

all appliances some excess air is used. This vol-

ume of excess air is added to the flue products

flowing from the appliance.

NOTE: Consult your local exhaust hood contrac -

tor for your specific installation.

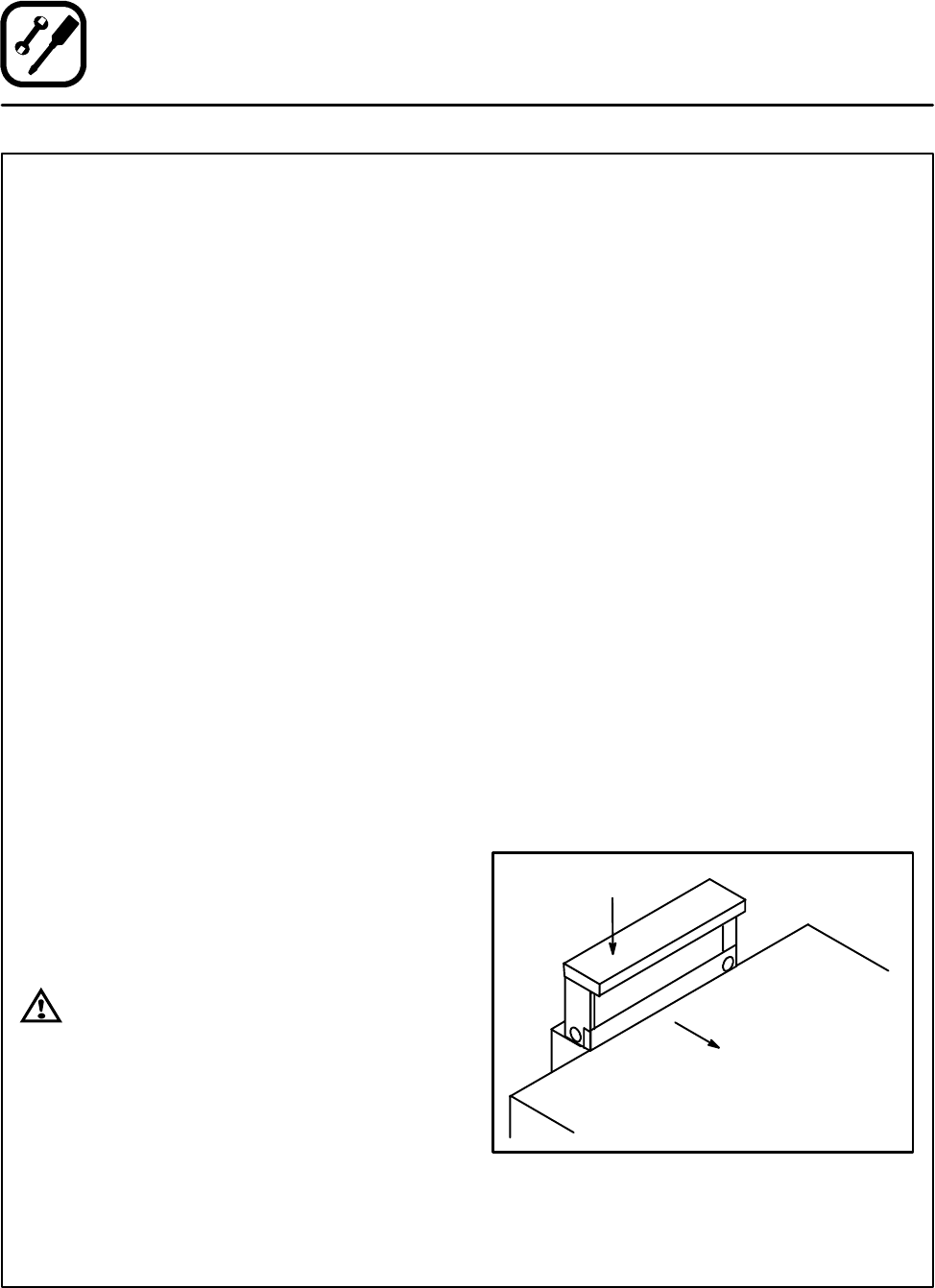

Installing the canopy hood draft diverter

Ovens ordered for hood venting are supplied with

a draft diverter. Install the draft diverter as follows:

1. Place the diverter over the flue connector with

the open area facing the front of the oven. See

Figure 6.

2. Secure both ends with the sheet metal screws

provided.

Front of

Oven

Draft Diverter

Figure 6