Model C709

057010-27

06/14

Taylor Company

2014 Carrier Commercial Refrigeration, Inc.

c

JP6 NO

JP7

JUMPER INSTALLED DISABLES RESET.

NO

RTCK

RESERVED (DO NOT USE)

NO

DBGEN

RESERVED (DO NOT USE)

NO

W1

RESERVED (DO NOT USE)

NO

JUMPER INSTALLED-FORCE BRUSH CLEAN STATUS.

JUMPER INSTALLED-OPEN ALL SOLENOIDS.

RESERVED (DO NOT USE)

W6

JUMPER INSTALLED-REDUCED MIX LOW SENSITIVITY.

NO

W7

JUMPER INSTALLED-REDUCED MIX OUT SENSITIVITY.

NO

PINS 1 & 2

JUMPER INSTALLED-ENABLES 59

F HOPPER

TEMPERATURE CHECK.

PINS 7 & 8

JUMPER INSTALLED W/SWITCH-SELF SERVE

APPLICATION ONLY. LOCKS OUT TOUCH

PANEL. NEW SWITCH ACTS AS THE ON/OFF

ABILITY TO ACTIVATE THE TOUCH PANEL.

NO

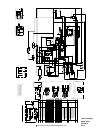

B

SOFT SERVE

PERSONALITY

BOARD

0-12 AMP BEATER MOTOR AMPERAGE RANGE YES

BROWN

J2

J3

GND

+5V

J5

1 2 3 4

5

6

J6

1 2 3 4 56

L1

7

J7

1 2 3 4 56 7

3 1

5

J8

J9

J12

J11

1234567

8

J10

12345678

9

10

B

A

J14

INTFC PCB A.

WITH SOFT SERVE

PERSONALITY PCB A.

7 8

J13

RED

WHT/RED

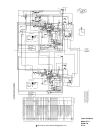

ON

OFF

BARREL

LIQUID

SOLENOID

HOPPER

LIQUID

SOLENOID

WHT/ORN

14

13

BEATER

INTERLOCK

RELAY

4

12

8

1

9

5

WHT

M

AGITATOR

MOTOR

SEE

DETAIL

WHT

24 VAC

COM

BLU/WHT

WHT

BLK/BLU

HOPPER

HOT GAS

SOLENOID

BARREL

HOT GAS

SOLENOID

BLU

BLU

BEATER

MOTOR

INTERLOCK

N.O. SWITCH

USER

INTERFACE

BOARD

0

1

3

4

2

7

8

6

0

1

3

4

2

7

8

6

HOPPER

HOT GAS

SOLENOID

RELAY

BARREL

HOT GAS

SOLENOID

RELAY

- 8 LEDS

- LCD SCREEN

- 9 KEYS

- BEEPER

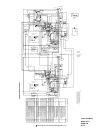

BLK

BLK

TAN

WHT

BLK

GRA/BLK

GRA

BLU/WHT

BLU/WHT

BLK YEL/BLK

BLK GRA

BLU

BLU/WHT

BLU/WHT

BLK

BRN/WHT

BRN/WHT

BRN/WHT

BRN/WHTBRN/WHT

RED

1

2

3

4

T8

T1

T7

T4

T5

BLACK

BLUE

BLACK

T1

CP

T2

L1

CP

L2

BEATER MOTOR

CONTACTOR

LEESON BEATER MOTOR WIRING

STEPS:

1) DISCONNECT WIRE T7 FROM TERMINAL 3

2) SPLICE BLUE WIRE AS SHOWN

1

2

4

6

BLACK

BLUE

BLACK

T1

CP

T2

L1

CP

L2

BEATER MOTOR

CONTACTOR

A.O. SMITH BEATER MOTOR WIRING

STEPS:

1) REMOVE BROWN JUMPER FROM BETWEEN TERMINAL #1 TO TERMINAL #5

2) MOVE BLUE INTERNAL (FROM MOTOR MAIN WINDING)

FROM TERMINAL #5 TO TERMINAL #1.

NOTE: FOR CCWLE - BLUE INTERNAL ON #1, YELLOW INTERNAL ON #6

BLUE INTERNAL

3

5

ORANGE INTERNAL

RED INTERNAL

YELLOW INTERNAL

BLACK INTERNAL

BLUE

BLUE

T3 L3

USE T3 AND L3 WHEN

CP CONTACTS ARE NOT AVAILABLE

T3 L3

USE T3 AND L3 WHEN

CP CONTACTS ARE NOT AVAILABLE

1

2

5

4

S

R

LINE

RELAY

START CAPACITOR

C

INTERNAL OVERLOAD

RUN CAPACITOR

SCHEMATIC WIRING DIAGRAM - CSR

1

2

5

4

C

S

R

LINE

RELAY

RUN

CAP.

START CAP.

COMPRESSOR

TERMINAL

COVER

ABOVE ELECTRICAL DIAGRAM SHOWS WIRING NECESSARY

TO HOOK UP A COMPRESSOR USING A START AND RUN

CAPACITOR (CSR) WITH A RELAY.

WHITE

BROWN

BLACK

BROWN

052396-1

EQUIPMENT

GROUND

BLEED RESISTOR

WHITE(120 VOLTS)

BLACK(230 VOLTS)

BLACK

BLUE

CLR (+5v)

BLK (GRD)

BLU

BRN/WHT

HOPPER

GROUND

BLUE

GRA/WHT

WHT/BRN

BLK

LIV

SOLENOID

BLK

M

L2

L1

T1

T2

AIR COOLED ONLY

COMPRESSOR

CONTACTOR

RED

WHT

M

BLU/WHT

BLUE

AGITATOR MOTOR

DETAIL

SE

BLUE

WHT

RED

SNUBBER

WHT

ORN

TAN

BLK

#3

#1

208

*C708*

NO

NC

DRAW

SWITCH

C0M

PANEL

JACK

ADDITIONAL DRAW SWITCH

FOR FLAVORBURST

BLACK

BLUE

BLACK

T1

CP

T2

L1

CP

L2

BEATER MOTOR

CONTACTOR

GE/RBC BEATER MOTOR WIRING

NOTE: FOR CCWLE - BLUE INTERNAL ON #1,YELLOW INTERNAL ON #2

BLUE

T3 L3

USE T3 AND L3 WHEN CP

CONTACTS ARE NOT AVAILABLE

J12 OR PURPLE INTERNAL

T1 OR BLUE INTERNAL

T8 OR RED INTERNAL

J9 OR BLACK INTERNAL

A

1

4

5

T4 OR YELLOW INTERNAL

2

FIG. 3

A

LEFT SYRUP HEATER

THERMOSTAT

140° OPEN

100° CLOSE

WHT

WHT

O.T.

RIGHT SYRUP HEATER

THERMOSTAT

140° OPEN

100° CLOSE

WHT

WHT

O.T.

BLK

BLK

WHT

GRN

WHT

C

NO

208-230 VAC

012626

WHT

OPTIONAL HEATED SYRUP RAIL

WHT

M

MIX

PUMP

MOTOR

BLK

BLU

23

4

RED

START

RELAY

ORN

PUR

YEL

WHT

FIG 2

ALTERNATE MIX PUMP MOTOR WIRING

NOTE:

1. STATIC ELECTRICITY MAY CAUSE

DAMAGE TO SOLID STATE COMPONENTS.

ELIMINATE STATIC ELECTRICITY BY

TOUCHING GROUNDED UNIT BEFORE

HANDLING SOLID STATE COMPONENTS.

2. RED WIRE ON RIBBON CABLES MUST BE

CONNECTED TO PIN 1 AT EACH END.

EXTERNAL

GROUND

L2

GROUND FRAME SECURELY

L1

TERMINAL BLOCK

BRN/WHT

INTERFACE BOARD

POWER TRANSFORMER

BLK

ORN

RED

BLU

16V

L2

LOAD

LINEL1

L1 L2

240V

WHT

NOT

CONNECTED

WHT

WHT

GRN/YEL

GRN/YEL

BLK

GRN/YEL

BRN/WHT

POWER

SWITCH

DPDT

BLK

ON

OFF

RED

BLU

GRN/YEL

BLK

BLK

BLK

BLK

BLK

HOPPERBARREL

--THERMISTOR PROBES--

BLK

BLK

YEL

YEL

RIBBON

CABLE

BLU

RED

MIX

LOW

PROBE

MIX

OUT

PROBE

PRP/WHT

PRP/WHT

GRN/YEL

GRA/BLK

RED/BLK

NO

NC

BLK

DRAW

SWITCH

COM

RIBBON CABLE

RED

BLU

RED

BLU

RED

BLU

RIBBON CABLE

WHT

WHT

WHT/ORN

RED

COMPRESSOR

CONTACTOR

COIL

BLK

M

MIX

PUMP

MOTOR

(SEE FIG 2)

BLK

OVERLOAD

SWITCH

23

4

WHT

RED

START

RELAY

BEATER

MOTOR

STARTER

COIL

WHT

ORN

WHT/ORN

BLK

BLKBLK

BEATER

MOTOR

OVERLOAD

SWITCH

BLK

BLK

COMPRESSOR

HIGH PRESSURE

LIMIT SWITCH

BLK

BLK

BLK

ORN/WHT

PURPLE

YEL

BARREL

SUCTION

SOLENOID

ORN

WHT

GRN/YEL

GRN/YEL

BLK

SV CABLE SV CABLE

BLK

BLK

BLK

BLK

BLK

BLK

BLK

BLK

BLK

BLK

BRN/WHT

M

T2

SOFT SERVE

COMPRESSOR

L2L1 T1

CONDENSER

FAN MOTOR

M

BLK BLK

BLUE

BLK

BEATER MOTOR

STARTER

BEATER MOTOR

STARTER

BLK

SOFT SERVE

BEATER MOTOR

BLK

BLK

BLK

BLK

CLR

ONE SIDE OF A

TWO WIRE CORD

FUSE

15A

4 5

EMI FILTER

UVC4

BOARD

FUNCTION

JUMPER

INSTALLED

INITIALLY

JP1

PINS 1 AND 2

JUMPER INSTALLED- BARREL AND HOPPER

TEMPERATURES ARE CHECKED DURING

AUTO/STANDBY. UNIT IS LOCKED OUT IF

EITHER BARREL OR HOPPER IS TOO WARM FOR

A PERIOD OF TIME. LOCKOUT OCCURS WHEN

BARREL OR HOPPER IS ABOVE 45

F (7 C)

FOR MORE THAN ONE HOUR OR ABOVE 41

F

(5

C) FOR MORE THAN FOUR HOURS.

YES

NO JUMPER INSTALLED-NO LOCKOUT DURING

AUTO/STANDBY IF BARREL OR HOPPER IS TOO

WARM FOR A PERIOD OF TIME.

PINS 3 AND 4

RESERVED (DO NOT USE)

NO

JP2 PINS 1 AND 2

DOMESTIC CONFIGURATION-JUMPER INSTALLED.

HOPPER TEMPERATURE NOT DISPLAYED ON

SCREEN/HEAT SYMBOL KEYS ONLY ACTIVE

WHEN A LOCKOUT CONDITION HAS OCCURRED/

STANDBY KEYS DISABLED.

YES

INTERNATIONAL CONFIGURATION-NO JUMPER

INSTALLED. HOPPER TEMPERATURES

DISPLAYED ON SCREEN/MANUAL HEAT CYCLE

START BY SELECTING HEAT SYMBOL/STANDBY

KEYS FUNCTIONAL.

JP3

RESERVED (DO NOT USE)

NO

JP4

RESERVED (DO NOT USE)

NO

JP5

RESERVED (DO NOT USE)

NO

RESERVED (DO NOT USE)

INTERFACE

BOARD

FUNCTION

JUMPER

INSTALLED

INITIALLY

W2 NO

W3

RESERVED (DO NOT USE)

NO

W4 NO

W5 NO

J10

YES

NO

A

SOFT SERVE

PERSONALITY

BOARD

0-6 AMP BEATER MOTOR AMPERAGE RANGE

BLK

BLK

BLK

M

WHT

PANEL SPINNER OPTION

SEE FIG. 1

BRN/WHT

M

BLK

BLK

BLK

BLK

BLK

WHT

LINE

LOAD

LINE FILTER

SPINNER MOTOR WIRING

FIG. # 1

LINE

GRN/YEL

WHT

WHT

WHT

BLK

BLK BLK

BLU/WHT

BLU

BLU

BLU

LOW PRESSURE

FAN SWITCH

WHT/GRA

BLU

BLU

JUMPER SETTINGS

WHT

WHT

L2

(SEE FIG 3)

J1

J3

GRD

+5V

J2

J11J10

J7

J1

1

2

UNIVERSAL CONTROL PCB A.

BLK

CLR

J9

J12

SHIELD CUT

NO CONNECTION

THIS END

J17

J15

J8

5

4

6

2

1

3

J13

J4

J16

3

4

2

7

8

6

1

5

RED

GRN

WHT

BLK

CABLE

RIBBON CABLE

RIBBON CABLE

BLK

YEL

SELF SERVICE

ENABLE

(OPTIONAL)

DISABLE

ENABLE

EQUIPOTENTIAL

GROUND

BLK

BLK

208/230 VOLTS, 60HZ

(DOMESTIC)

L1

L2

208/230 VOLTS, 60HZ

(INTERNATIONAL)

L1

L2 OR N

WIRE COLORS - BASED ON INCOMING POWER

FIG. 4

BLK

BLK

GRN/

YEL

GRN/

YEL

GRN/

YEL

GRN/

YEL

GRN/

YEL

GRN/

YEL

(SEE FIG.4)