30

Models C708 & C716Important: To the Operator

The third screen shows the right side (R) of the

freezer.

The top line of t hese screens shows the hopper (H)

and barrel (B) temperatures recorded at the end of

the Heat Treat Cycle and indicates the side ( L or R)

of the freezer.

The remaining lines indicate the following:

HEAT = Total time for the hopper ( h) and barrel (b)

to reach 150.9°F (66.1°C).

OVER = Total time the hopper (h) and barrel (b)

temperature was abov e 150° F (65.6°C).

COOL = Total time the hopper (h) and bar rel (b)

temperature was abov e 41° F (5°C) during the CO OL

phase.

PEAK = Highest temperature reading for the hopper

(h) and barrel (b) dur ing t he Heat Treatment Cycle.

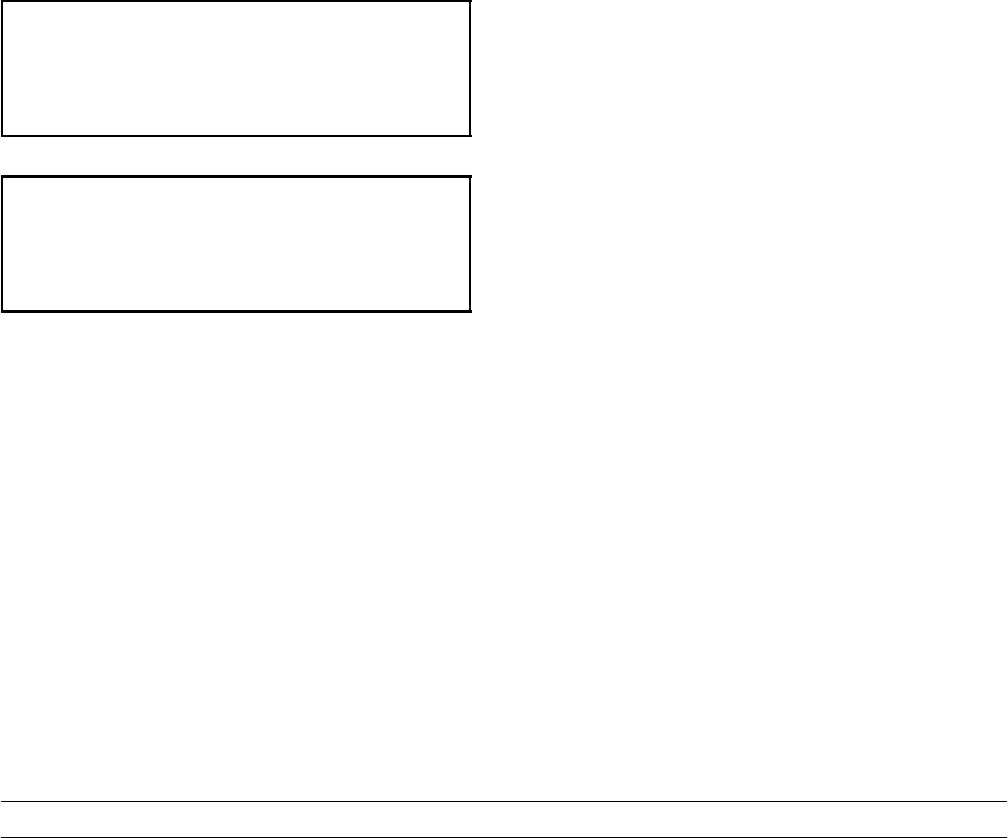

H: 40.9 B:26.3 L

HEAT OVER COOL PEAK

1:12 0:49 h 1:19 161.0

0:46 1:11 b 0:15 169.7

H: 38.0 B:23.7 R

HEAT OVER COOL PEAK

1:09 0:52 h 1:11 161.2

0:66 1:00 b 0:11 169.9

The HEAT time indicates the amount of time taken

in each z one t o reach 150.9°F (66.1°C). Each zone

must remain above 150° F (65.6°C) for a minimum of

35 minutes.

Touch the UP arrow symbol to advance to the nex t

page or the DOWN arrow symbol to view the

previous page. A Heat Cycle Failure message will

display on the first screen if a failure oc curred.

Listed below are v ariable failure code messages

which could appear on line 2.

HT HEAT TIME FAILURE

Mix temperature did not rise above 151_F

(66.1_C) in les s than 90 minutes.

CL COOL MODE FAILURE

Mix temperature i n the hopper and freezing

cylinder did not fall below 41_F(5_C) in less

than 90 minutes.

TT TOTAL TIME FAILURE

The heat treatment cycle must be completed

in no more than 4 hour s.

ML MIX LOW FAILURE

The Heat Phase or Cool Phase time was

exceeded and a mix low c ondition was

present.

MO MIX OUT FAILURE

A mix out condition was detected at the s tart

or during the heat cycle.

BO BEATER OLVD IN HC

A beater overload occurred during the heat

cycle.

HO HPCO IN HEAT CYCLE

A high pr essure cut-out condition occurred

during the heat cycle.

PF POWER FAILURE IN HC

A power failure caused the Heat Phase,

Cool Phase, or Total Cycle Time to exceed

the maximum allowed time. If a power failure

occurs, but the heat treatment cycle does

not fail, an asterisk(*) will appear on the third

line of the dis play.

OP OPERATOR INTERRUPT

Indicates the heat cycle was aborted in t he

OPERATOR INTERRUPT option in the

Service Menu.

PS POWER SWITCH OFF

The power switch was placed int o t he O FF

position during the heat cycle.

TH THERMISTOR FAILURE

A thermistor probe has failed.

PD PRODUCT DOOR OFF

A product door is not in place or is loos e.