32

Models C708 & C716Operating Procedures

Section 6 Operating Procedures

The C708 stores mix in a hopper and has a 3.4

quart (3.2 liter) capacity freezing cylinder with a

single spout door. The C716 s tores mix in two

hoppers and has t wo 3.4 quart (3.2 liter) capacity

freezing cylinders with a three s pout door.

The Model C708 has been selected to illustrate the

step-by-step operating procedures. Duplicate the

procedures, where they apply, for the second

freezing cylinder on the Model C716.

We begin our instructions at the point where we

enter the store in the morning and find the parts

disassembled and laid out to air dry from the

previous night's cleaning.

These opening procedures will show y ou how to

assemble these parts into the freezer, sanitize them,

and prime the freezer with fresh mix in preparation

to serve your first portion.

If you are disassembling the machine for the first

time or need information to get to t his s tarting point

in our ins tructions, turn to page 47, “Disassembly”,

and start there.

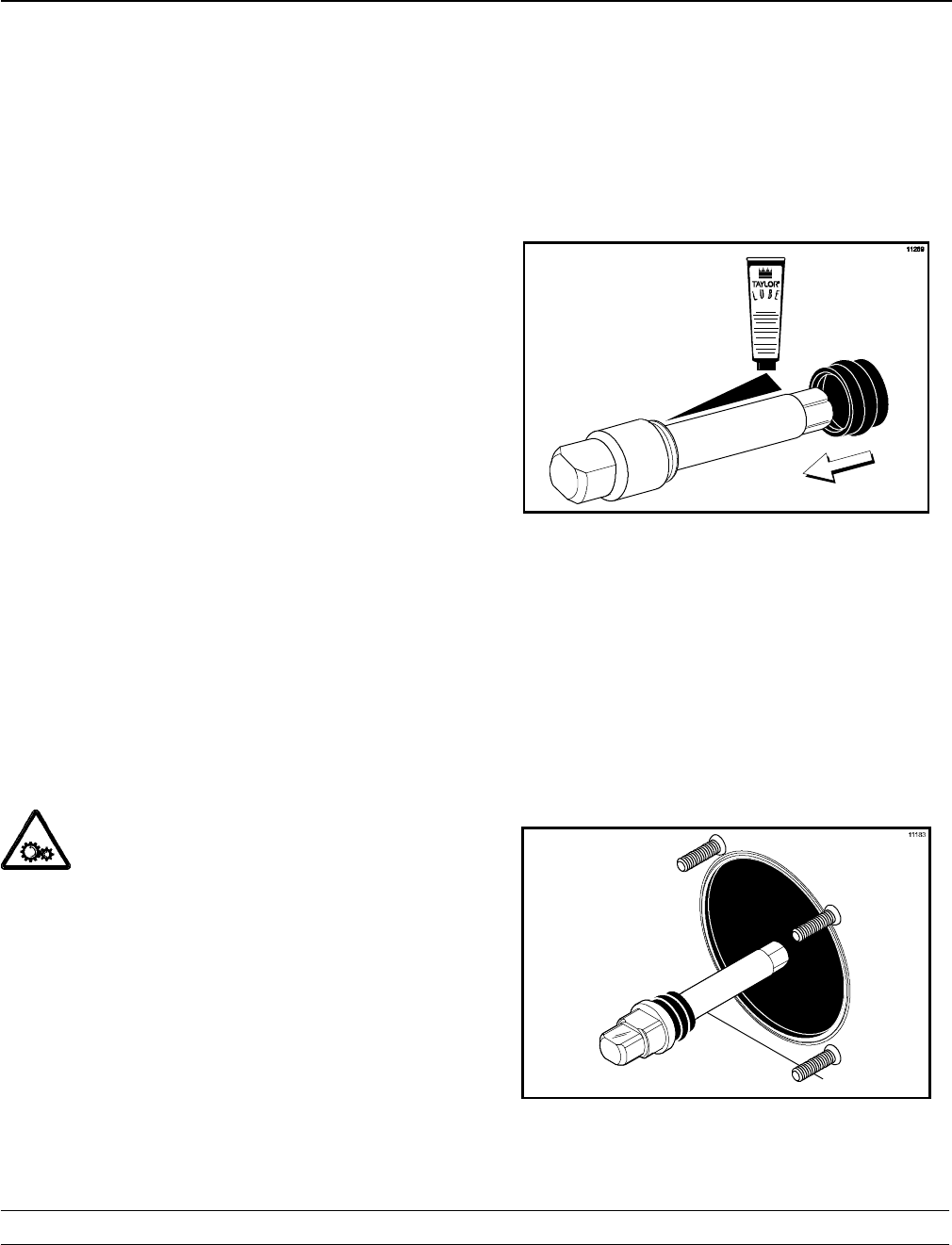

Freezing Cylinder Assembly

Note: When lubricating parts, use an appr oved food

grade lubricant (example: Taylor Lube).

MAKE SURE THE POWER SWITCH IS IN

THE “OFF” POSITION! Failure to follow this

instruction may result in severe personal injury from

hazardous moving parts.

Step 1

Before installing the beater drive shaft, lubricate the

groove on the beater drive s haft.

Step 2

Slide the beater drive shaft boot seal over the s mall

end of the beater dr ive shaft and engage into the

groove on the s haft.

Step 3

Heavily lubricate the inside portion of the boot seal

and also lubr icate the flat end of the boot seal that

comes in contact with the rear shell bearing.

Step 4

Apply an e ven c oat of lubr icant to the shaft. DO

NOT lubricate the hex end. ( See Figure 12.)

Figure 1 2

Note: To ensure the mix does not leak out of the

back of the freezing cylinder, the middle s ection of

the boot seal should be c onvex or ex tend out from

the seal. If the middle section of the boot seal is

concave o r extending into the middle o f the s eal,

turn the s eal ins ide out.

Step 5

Insert the beater drive shaft through the rear s hell

bearing in the f reezing cylinder and engage the hex

end firmly into the drive coupling. (See Figure 13.)

Figure 1 3