6712FR Refrigerated Sampler

Section 2 Installation/Preparation

2-9

2.5 How Does the Sampler

Work?

When the sampler takes a sample, it draws liquid through the

strainer and suction line to the pump tube. The liquid flows

through the pump tube and past the liquid detector, which senses

the liquid. From the detector, the liquid follows the pump tube

through the pump to the bulkhead fitting and then through the

discharge tube to the sample bottle.

A typical sampling cycle consists of:

1. The sampler moves the distributor arm over the bottle that

is to receive the sample.

2. The pump reverses for the pre-sample purge.

3. The pump direction changes, filling the suction line.

4. When the detector senses liquid, the sampler begins mea-

suring the sample.

5. After depositing the sample, the pump again reverses for

the post-sample purge.

Sampling cycles vary somewhat according to program settings

for distribution. The sampler can move the distributor arm

clockwise and counterclockwise, making a number of distribution

methods possible. (In this manual, the words “sample event”

refer to a full sampling cycle for any distribution.)

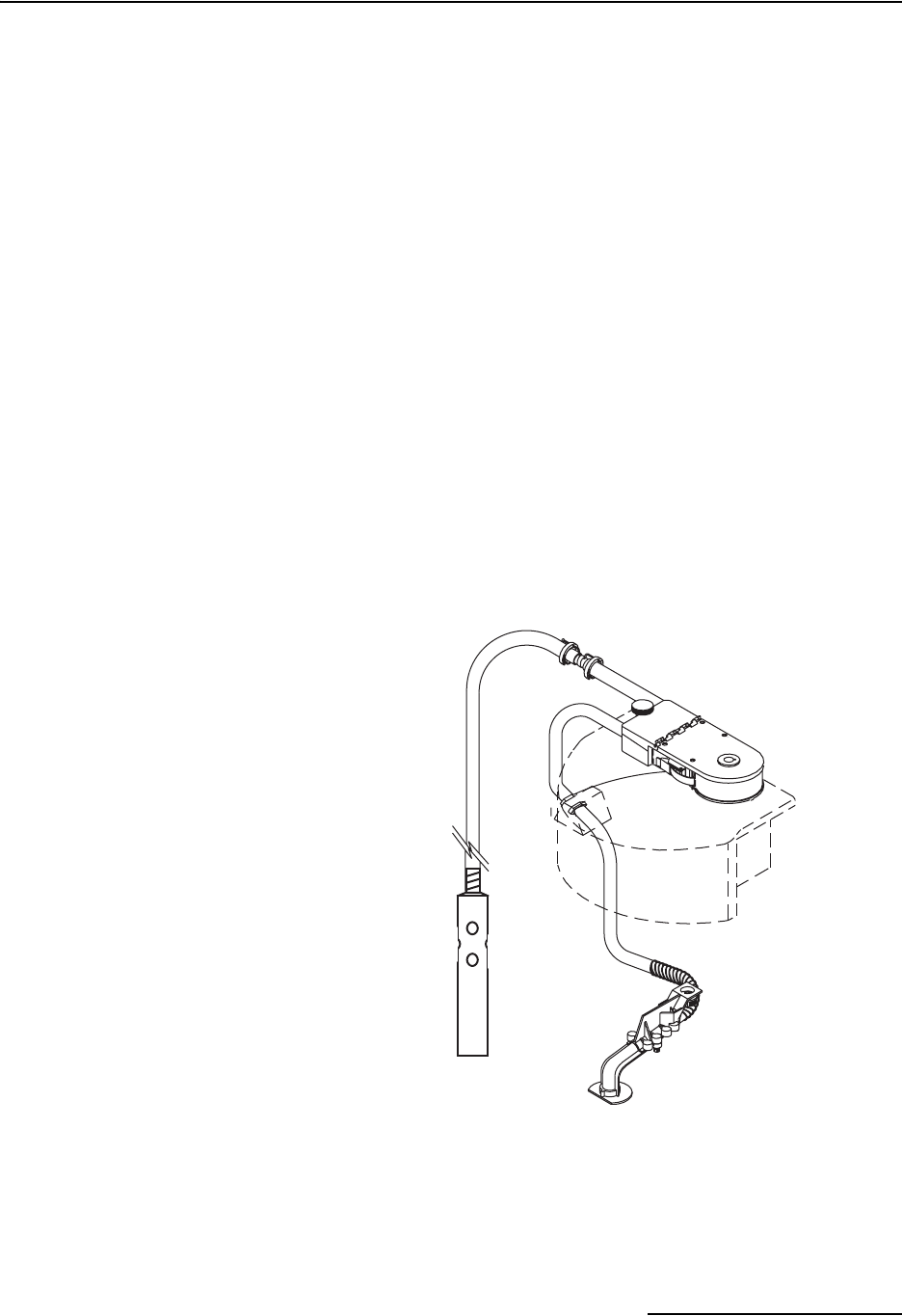

Figure 2-6 Identifying the Sampler Components

Other variations include extended-program settings for

suction-line rinses and sampling retries. A sampler running a

program with line rinses completes the pre-sample purge and

a

i

b

d

j

h

e

f

g

c

a. Controller.

b. Peristaltic pump.

c. Liquid Detector.

d. Strainer

e. Suction line

f. Stainless Steel Coupling

g. A pump tube routed from the liq-

uid detector’s intake port

through the pump, out the detec-

tor’s discharge port, and over the

side of the controller to a bulk-

head fitting.

h. Bulkhead fitting.

i. Discharge tube running from the

bulkhead through the spring and

distributor arm.

j. Distributor arm and spring.