1

THEORY OF OPERATION, SPECIFICATIONS AND INSTALLATION

T

HEORY OF OPERATION

The TurboChef

®

High h Batch speed cook oven

uses high heat transfer rates developed by force air

impingement to rapidly cook food. The High h

batch utilizes top and bottom Jetplates that have

been optimized for specific food items. The plates

can be easily removed and replaced to facilitate

either higher or lower heat transfer rates. As a result,

the operator can cook foods that require maximum

browning/caramelizing (high heat transfer), or more

delicate foods that require low heat transfer to

ensure quality is not compromised.

The technology is similar to but about twice as fast

as the fastest impingement conveyor oven. The High

h Batch utilizes a variable speed blower, oscillating

rack, and Catalytic Converter to provide maximum

speed, minimal energy input, ventless operation and

the highest food quality.

CERTIFICATIONS

UL, cUL, NSF

D

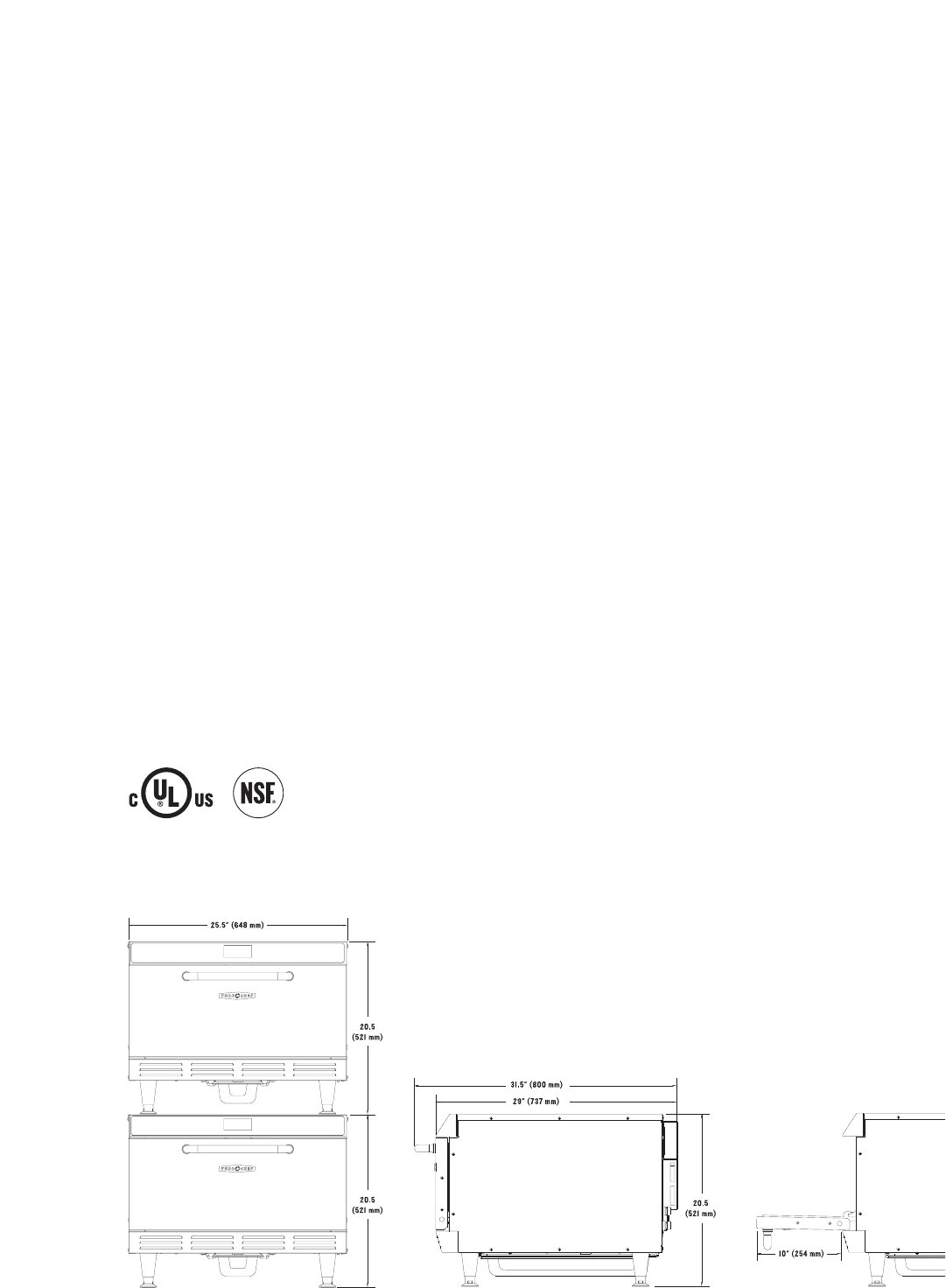

IMENSIONS

Single Units

Height 20.5

′′ (521 mm)

Width 25.5

′′ (648 mm)

Depth 29

′′ (737 mm)

with handle 31.5

′′ (800 mm)

Weight 157 lbs. (71 kg)

Double Units (requires Stacking Kit)

Height 41

′′ (1042 mm)

Width 25.5

′′ (648 mm)

Depth 29

′′ (737 mm)

with handle 31.5

′′ (800 mm)

Weight 314 lbs. (42 kg)

Cook Chamber

Height 8′′ (203 mm)

Width 18.75

′′ (476 mm)

Depth

16.75

′′ (425 mm)

Volume 1.45 cu. ft. (41.1 liters)

Wall Clearance

Top 2′′ (51 mm)

Sides 2

′′ (51 mm)

: High h Batch Dimensions