Head Pressure Control

EXV UNITS (All 30GN units except 040 and 045 with op-

tional brine) — The microprocessor controls the condenser

fans in order to maintain the lowest condensing temperature

possible, thus the highest unit efficiency. Instead of using the

conventional head pressure control methods, the fans are con-

trolled by the position of the EXV and suction superheat.

As the condensing temperature drops, the EXV opens to

maintain the proper suction superheat. Once the EXV is fully

open, if the condensing temperature continues to drop, the

suction superheat begins to rise. Once the suction superheat

is greater than 40 F (22.2 C), a fan stage is removed after

2 minutes.

As the condensing temperature rises, the EXV closes to

maintain the proper suction superheat. Once the EXV has

closed to 39.5% open (600 steps open), a fan stage is added

after 2 minutes.

During start-up, all the condenser fans are started when

the condensing temperature reaches 95 F (35 C) to prevent

excessive discharge pressure during pulldown. See Table 5

for condenser fan sequence of operation.

For low-ambient operation, the lead fan in each circuit can

be equipped with the optional or accessory Motormaster

III head pressure controller. This control has its own sensor

which is mounted on a return bend in the liquid portion of

the condenser. It will vary the fan speed to maintain a satu-

rated condensing temperature of 100 F. The controls auto-

matically default to condensing temperature control during

this first stage of condenser-fan operation. When subsequent

fan stages start, the controls revert to EXV fan control.

TXV UNITS (30GN040,045 with optional brine only) —

Head pressure control is based on set point control. The micro-

processor stages the condenser fans to maintain the set point

temperature specified by the controller.

Pumpout

EXV UNITS — When the lead compressor in each circuit

is started or stopped, that circuit goes through a pumpout

cycle to purge the cooler and refrigerant suction lines of

refrigerant.

The pumpout cycle starts immediately upon starting the

lead compressor and continues until the saturated suction tem-

perature is 10° F (5.6° C) below the saturated suction tem-

perature at start-up, is 10° F (5.6° C) below the cooler leav-

ing fluid temperature, or reaches a saturated suction temperature

of –15 F (–26 C). No pumpout is necessary if the saturated

suction temperature is below –15 F (–26 C). At this point,

the EXV starts to open and continues to open gradually to

provide a controlled start-up to prevent liquid flood-back to

the compressor.

At shutdown, the pumpout cycle continues until the satu-

rated suction temperature for that circuit is 10° F (5.5° C)

below the saturated suction temperature when pumpout is

initiated, or saturated suction temperature reaches –15 F

(–26 C). At that point, the compressor shuts down and the

EXV continues to move until fully closed.

TXV UNITS — Pumpout is based on timed pumpout. On a

command for start-up, the lead compressor starts. After

10 seconds, the liquid line solenoid opens. At shutdown, the

liquid line solenoid closes, and the lead compressor contin-

ues to run for 10 seconds before stopping.

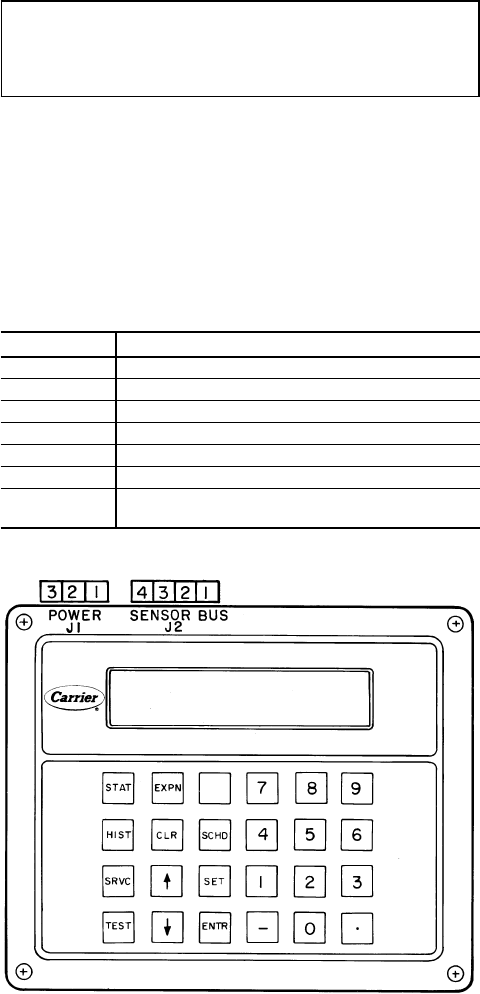

Keypad and Display Module (Also Called HSIO

or LID) —

The only function of this module is to allow

the operator to communicate with the processor. It is used to

enter configurations and set points and to read data, perform

tests, and set schedules. This device consists of a keypad

with 6 function keys, 5 operative keys, 12 numeric keys

(0 to 9, •, and -), and an alphanumeric, 8-character LCD. See

Fig. 4. See Table 6 for key usage.

IMPORTANT: When entering multiple character in-

puts beginning with a zero, a decimal point must be

entered in place of the first zero. When entering an in-

put of zero, only the decimal point need be entered.

ACCESSING FUNCTIONS AND SUBFUNCTIONS — See

Tables6-8.Table 7 shows the 6 functions (identified by

name) and the subfunctions (identified by number).

AUTOMATIC DEFAULT DISPLAY — When keypad has

not been used for 10 minutes, display automatically switches

to the rotating automatic default display. This display has

7 parts, listed below, which appear in continuous rotating

sequence.

DISPLAY EXPANSION

TUE 15:45 TODAY IS TUE, TIME IS 15:45 (3:45 PM)

LOCAL ON UNIT IN LOCAL MODE

CLOCK ON UNIT IS ON VIA CLOCK SCHEDULE

8 MODE TEMPERATURE RESET IN EFFECT

COOL 1 NUMBER OF STAGES IS 1

2 ALARMS THERE ARE 2 ALARMS

3 MINS

3 MINUTES REMAINING IN THE OFF-TO-ON

TIME DELAY

Fig. 4 — Keypad and Display Module

24