5 - 16 5 - 16

MELSOFT

5 BASIC OPERATIONS

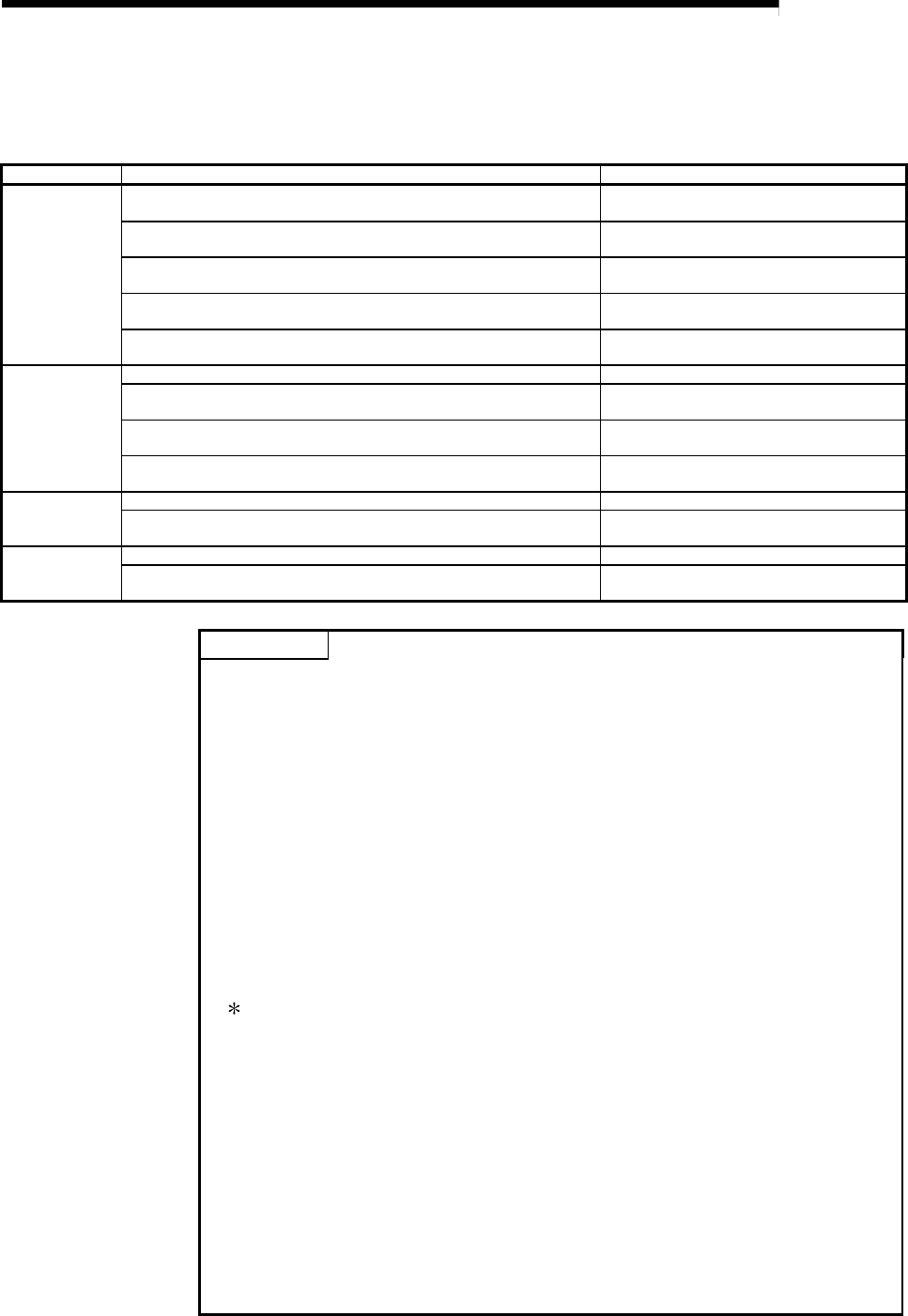

(3) Paths connectable using GX Explorer

The following table indicates the paths connectable using GX Explorer on a PLC

series basis.

PLC Series Description Name in Connection Path List

Connected to the PLC CPU from the serial port by the RS-232 cable or

from the USB connector by the USB cable.

Serial port PLC module connection

Connected to the MELSECNET/10(H) network module by the

MELSECNET/10(H) board.

MNET/10 (H) board communication Access

other station via MNET/10 (H) module

Connected to the CC-Link master/local module by the CC-Link board.

CC-Link board communication Access other

station via CC-Link module

Connected to the Ethernet interface module by the Ethernet board.

Ethernet board communication Access

other station via Ethernet module

QCPU

(Q mode)

Connected to the remote I/O station of MELSECNET/H from the serial

port by the RS-232 cable.

Serial port NET/10 (H) remote module

connection

Connected to the PLC CPU from the serial port by the RS-232 cable. Serial port PLC module connection

Connected to the MELSECNET/10 network module by the

MELSECNET/10(H) board.

MNET/10 (H) board communication Access

other station via MNET/10 (H) module

Connected to the CC-Link master/local module by the CC-Link board.

CC-Link board communication Access other

station via CC-Link module

QnACPU

Connected to the Ethernet interface module by the Ethernet board.

Ethernet board communication Access

other station via Ethernet module

Connected to the PLC CPU from the serial port by the RS-232 cable. Serial port PLC module connection

QCPU

(A mode)

Connected to the MELSECNET/10 network module by the

MELSECNET/10(H) board.

MNET/10 (H) board communication Access

other station via MNET/10 (H) module

Connected to the PLC CPU from the serial port by the RS-232 cable. Serial port PLC module connection

ACPU

Connected to the MELSECNET/10 network module by the

MELSECNET/10(H) board.

MNET/10 (H) board communication Access

other station via MNET/10 (H) module

POINT

• A communications error may occur if communications are made with the PLC

after setting the resume function, suspend setting, power-saving function or

standby mode of the personal computer.

Hence, any of the above functions should not be set for making communications

with the PLC.

• When the USB cable is used, frequently unplugging/plugging the USB cable,

resetting the PLC CPU, or switching power OFF/ON during communications with

the PLC CPU may cause a communications error, from which a recovery cannot

be made.

During communications, do not unplug/plug the USB cable, reset the PLC CPU,

or switch power OFF/ON.

If a recovery cannot be made from a communications error, unplug the USB

cable completely once, wait for more than five seconds, and then plug it again.

(After performing this operation, an error may occur at initial communication but

operation will be normal at and after the second time.)

During communications: Indicates that the related application in the PLC side

window is being run, write to PLC (paste) or read from PLC (copy) is being

performed, the network configuration information is being updated, the PLC data

is being deleted, or diagnostics, connection station check or total station check is

being made.

• Communication errors may occur depending on the type of personal computer

used or USB cable assembly In this case.

Please execute communication again according to the error message contents.

• When fast communication is made after the baud rate has been changed on the

personal computer's serial port (personal computer side interface),

communications may not be made or communications retries may take place to

delay communications, depending on the performance of the personal computer.

If communications cannot be made in fast communication, reduce the baud rate

and make communication.