INSTALLATION INSTRUCTIONS

19 RC231002 Rev. 3

minutes, no longer. Be sure the liquid completely covers

the cap and base portion of the assembly. After 20

minutes, remove burner, cool slightly and rinse thoroughly

with cold water. Be sure hands are protected to prevent

burns from hot water. Be sure all the solution is completely

rinsed off both the inside and outside of the burner. If some

stains still remain, rub with a "Dobie" pad.

The burner may then be left to dry at room temperature or

be placed in the oven at 170° for 1/2 hour. BE SURE TO

PROTECT YOUR HANDS WHEN REMOVING DRIED

BURNERS FORM THE OVEN.

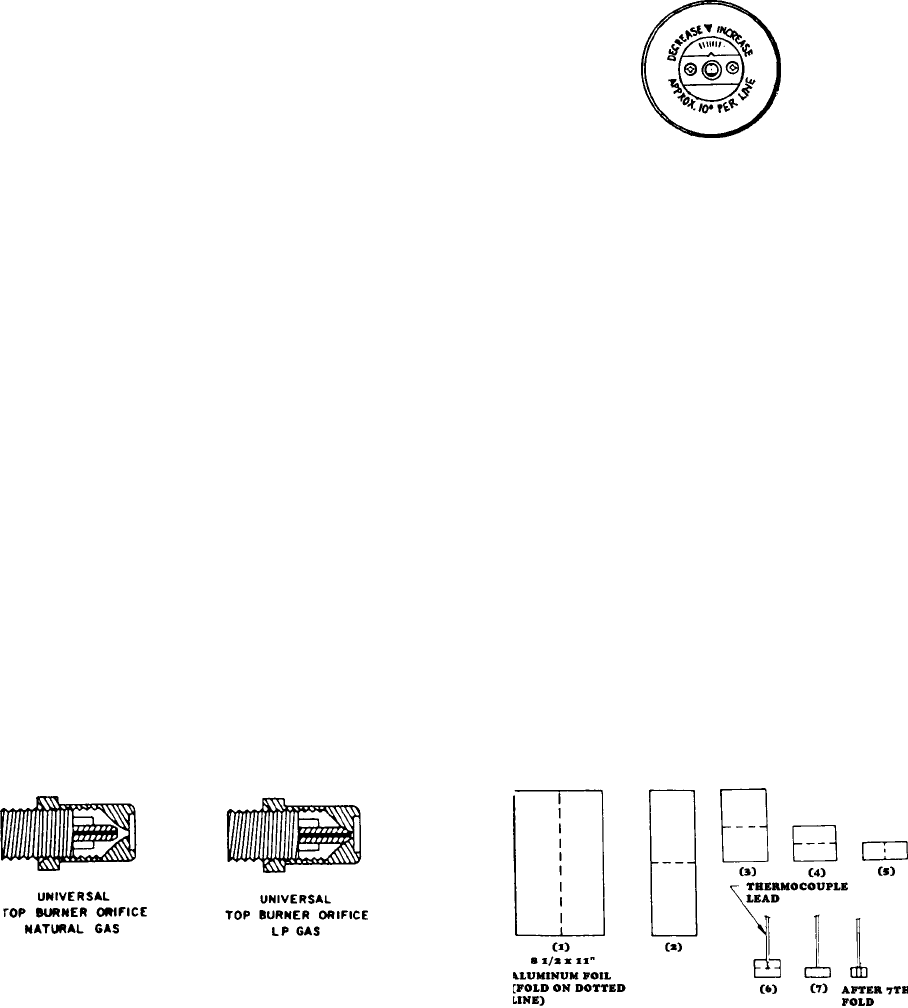

UNIVERSAL GAS ORIFICES

With the exception of the Broiler Burner and Sealed Top

Burner, orifices for these models are of the coaxial type.

They contain a double coaxial orifice hood and universal

pin. The hood orifice is sized for Natural Gas (6 inches

water column pressure). The pin orifice is sized for LP Gas

(11 inches water column pressure).

The orifice is adjusted for Natural gas as shipped from the

factory. It must be adjusted for use on LP gas. This

requires that the orifice hood be screwed or turned down

approximately two (2) turns onto the pin. The hood should

be turned down snug but not tight to the point where it

damages or distorts the pin. (See Figure 19.)

When set up for Natural Gas, gas flows around the pin and

through the orifice of the hood which is sized for Natural

Gas. When the hood is screwed down for LP gas, the gas

flow is only through the hollow pin which is sized for LP gas.

Figure 30 - Universal Orifice

OVEN THERMOSTAT KNOB ADJUSTMENT

Models without electronic Range Control (ERC)

Cooking recipes are written to take into consideration that

oven thermostats have manufacturing tolerances, and

may not provide an average temperature exactly on the

thermostat setting. If the temperature average reading is

beyond the ±25° tolerance range, a limited adjustment can

be made with the adjustable skirt on the knob. The

adjusting screw on the thermostat is sealed and no adjust-

ment can or should be attempted. The rear of the adjust-

able skirt shown here is self-explanatory.

Figure 31

NOTE: These thermostats (Robertshaw) have a cement

coating over the adjusting screw. Evidence of attempts to

adjust these thermostat nullifies the warranty.

For Thermostat Calibration on models with the Elec-

tronic Range Control (ERC), see section on ERC

Operating and Testing Procedures.

When making any temperature adjustments, a reliable test

instrument should be used to accurately determine the

oven temperature.

A reliable test instrument of the thermocouple type is

preferred which will allow temperature readings with the

door closed.

Position the thermocouple clip of the test instrument on the

center of the oven rack that is positioned in the center of the

oven cavity. The thermocouple of the test instrument

should be "weighted" or "loaded" in order to represent more

closely the average cooking temperature of the oven

versus the on-off cycling of the thermostat with the full rate

gas valve. The procedure for loading a thermocouple is

illustrated in Figure 20.

Figure 32 - "Loading" A Thermocouple

An 8 1/2 x 11-inch piece of aluminum foil should be folded

five (5) times, doubling the thickness with each fold. After

the fifth fold, place the thermocouple in the center of the

aluminum piece as shown and fold once more. Finally, fold

the sides so the foil clings to the thermocouple. The loaded

thermocouple will then provide temperature readings on

the thermometer that more closely resemble the mean or

average temperature of the oven as it cycles on and off

above and below the temperature setting.

With all the controls properly set for "Bake", turn the oven

thermostat to 350°.