OPERATION AND SERVICE PROCEDURES

RC231002 Rev. 3 62

either timer switch contacts 1 to 2 or 3 to 4. Press

"SET" button twice (Auto Program) and rotate "SET"

knob for approximately ten (10) to fifteen (15) sec-

onds. Meter needle should swing to zero (0) ohms

(continuity) indicating a closed switch. Repeat the

procedure after transferring the test leads to the other

switch contacts. Allow countdown to complete, the

alarm should sound, and the meter indicate open

contacts. NOTE: A slight "click" can be heard

whenever the relay switches open or close.

TO AVOID THE RISK OF ELECTRICAL SHOCK,

PERSONAL INJURY OR DEATH DISCONNECT POWER

BEFORE SERVICING, UNLESS TESTING REQUIRES

IT.

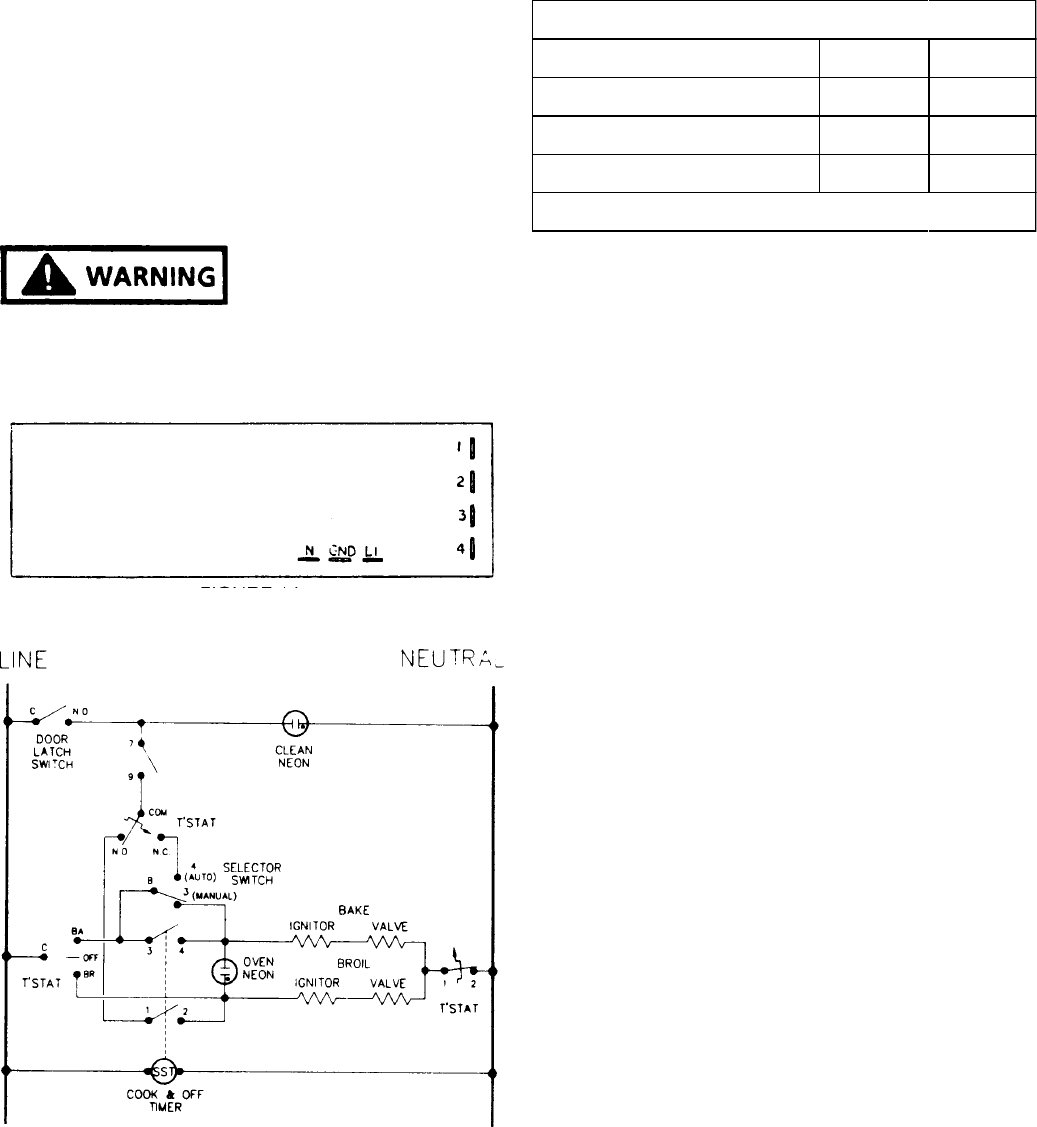

Figure 63 - Cook And Off Timer - Rear View - Partial

Figure 64 - Cook And Off Timer Switch Circuits

CLOCK TIMER

FUNCTION 1 - 2 3 - 4

MANUAL

0 0

COOKING IN AUTO

X X

AUTO COMPLETE

0 0

O = OPEN X = CLOSED

Timer Switching Schedule

BAKE AND BROIL IGNITORS

The bake and broil ignitors are mounted to the bake and

broil burners and ignite the gas flowing into the burner.

During a broil or manual bake operation, current flows

through the ignitor, gas valve, selector switch, and thermo-

stat to neutral. As the ignitor starts heating up and glowing,

its internal resistance decreases allowing more current to

flow through the bake or broil circuit. When the circuit

current reaches approximately 3.2 - 3.6 amps, the bi-metal

arm in the gas valve flexes, opening the valve, allowing

gas to flow to the burner where it is ignited by the glowing

ignitor. The ignitors will glow anytime the bake or broil

burners are in operation and cycle on and off with the

thermostat cycling contacts.

The operation of the OVEN/BROILER "ELECTRIC IGNI-

TOR" can be checked by using a VOLT/OHMMETER as

follows: NOTE: This check must be made while the ignitor

is at ambient room temperature.

1. Disconnect electricity.

2. Set the volt/ohmmeter on the RX1K ohms scale.

(Zero the meter.)

3. Remove ignitor from burner.

4. Remove ignitor lead wire nuts and disconnect ignitor

leads from range wiring.

5. Connect ohmmeter leads to ignitor wire leads.

6. If the meter indicates continuity (a low resistance

reading), the ignitor is operative. NOTE: The cold

resistance measurement can vary several hundred

ohms. However, this test is for continuity without a

dead short (zero ohms).