OPERATION AND SERVICE PROCEDURES

73 RC231002 Rev. 3

ignition circuit. One terminal of each switch is connected

to the 120 VAC line while the other terminal connects to the

"L1" module terminal. Terminal "N" of the module con-

nects to the common or neutral side of the AC line. The

spark switch is located on the stem of the top burner valve.

A continuity test can be made to check for proper switch

operation. Shut off power to the range and remove the

switch wiring. Set an ohmmeter to the RX1 scale and

attach the meter leads to the switch terminals. When the

switch is turned to the "LITE" position, zero (0) OHMS

(closed contacts) should be indicated. Infinite OHMS

(open contacts) should be indicated in all positions except

"LITE". If the switch fails this test, it must be replaced.

DOOR LATCH MECHANISM

The door latch mechanism is used to insure the oven door

is sealed tightly against the chassis during the clean cycle.

The latch cannot be moved to the "CLEAN" position unless

the door is closed. A thermal safety "jams" the lock

mechanism during the clean cycle to prevent accidental

opening of the door latch during cleaning. When the latch

is jammed the latch cannot be moved to the "COOK"

position.

After the cleaning is completed and the oven cools, the

latch is released and can be moved again to the "COOK"

position.

FIRE OR EXPLOSION

TO AVOID THE RISK OF ELECTRICAL SHOCK,

PERSONAL INJURY OR DEATH DISCONNECT POWER

BEFORE SERVICING, UNLESS TESTING REQUIRES

IT.

LATCH SWITCH

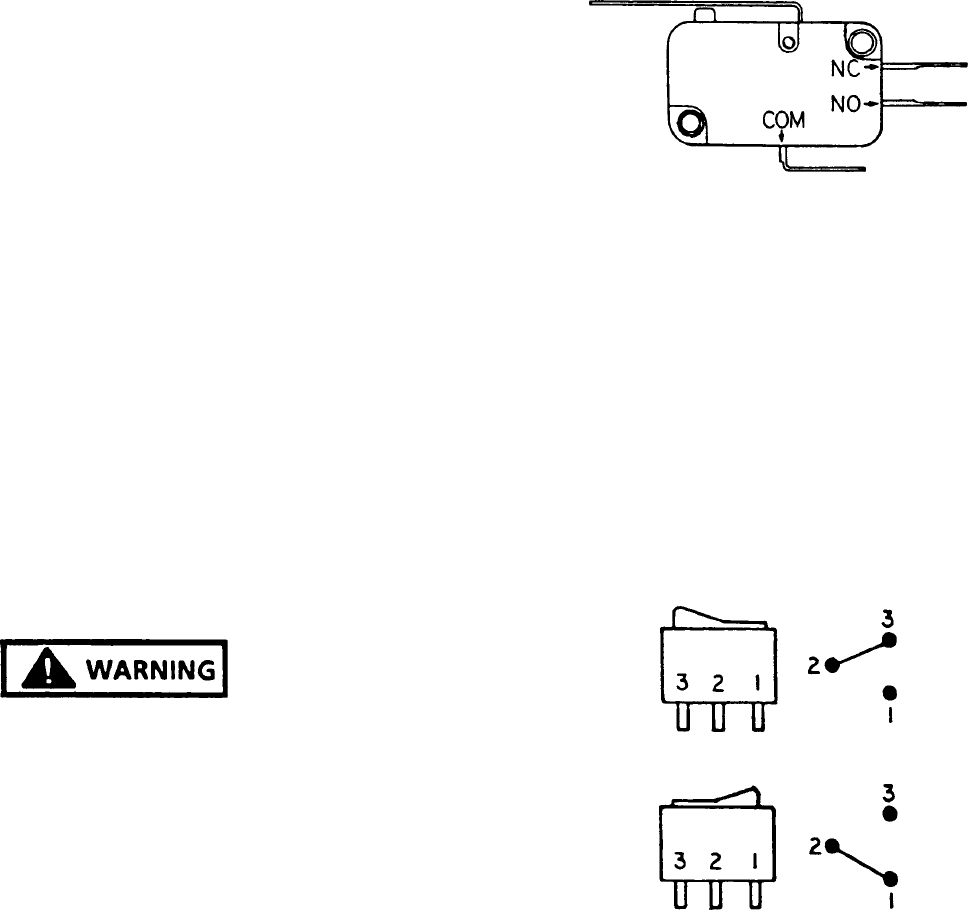

The door latch switch is a single pole, double throw switch.

It is used to complete the self-clean cycle. On models

without the ERC, it also completes the circuit to the

"CLEAN" indicator. It is mounted on the door latch

mechanism.

The Switch Contacts can be Checked as Follows:

1. Shut off power to the range.

2. Disconnect the switch wire leads and check the COM

- N.O. and COM - N.C. contacts for continuity.

3. When the door latch is in the left or unlocked position,

the COM - N.O. contacts should be open and the

COM - N.C. contacts should be closed.

4. Move the door latch to the far right or locked position.

The COM - N.O. contacts should be closed and the

COM - N.C. contacts should be open.

Figure 74 - Latch Switch

ROCKER SWITCH TESTING

The rocker type switch on these models is a single pole,

double throw switch used to control the oven light. The

rocker switch contacts can be checked for continuity by

using an ohmmeter set to the RX1 scale or a continuity

tester. Set the switch to the position as shown in Figure 31

and connect the meter or tester leads to terminals 2 - 3 and

then to terminals 1 - 2. Continuity should be indicated

across terminals 2 - 3 and open contacts should be

indicated across terminals 1 - 2.

Set the rocker switch to the position as shown in Figure 32.

Continuity should be indicated across terminals 1 - 2 and

open contacts indicated across terminals 2 - 3. If the switch

fails either test, it should be replaced.

Figure 75

Figure 75A

FLUORESCENT LIGHT SYSTEM

The fluorescent light system incorporates a light switch,

fluorescent starter and ballast in conjunction with the

fluorescent lamp. Momentarily depress the lamp switch.

The lamp should light and remain lit until the switch is

depressed a second time.

TO TEST THE FLUORESCENT LIGHT SWITCH

1. Shut off power to the range.

2. Disconnect switch leads to wire nuts.